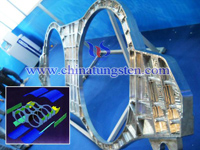

WHA Balance Weight

- Details

- Category: Tungsten Information

- Published on Friday, 31 May 2013 15:24

- Hits: 2124

Drivers consistently report they can sense differences in how a car handles on the track if the weight on a given wheel varies only by a couple of pounds. Fine tuning a car to a given track is a very cumbersome and time consuming ordeal with conventional lead plate weights. WHA balance weight offers up to 50% more weight in a given volume, with the added advantages of direct attachment via threaded holes or thru-bolting and the freedom from deformation. The high density of WHAs permit weights to be placed in the lower half of NASCAR weight adjustment tubes, effectively lowering the overall center of gravity for improved handling. Tungsten product has a specialized line of racing weights for these applications.

Tungsten heavy alloy (WHA) balance weight of racing car is now becoming the most popular material for ballast, due to its main advantages as follows:

Highest density

Adding WHA balance weight into the whole framework of a racing car is helpful to optimize the performance of the racing car during the racing progress, which contributes to the better control of the car's movement.

High tensile strength and good creep resistance

Tungsten has high tensile strength and good creep resistance with a high mass/size ratio, so it will be the ideal to work in a restricted space. Its high density also gives enhanced sensitivity by increasing the control of load distribution.

Machined Easily

WHA is also easily machineable which gives designers greater flexibility in deciding on the final shape of components and offer designers several advantages over conventional balance materials e.g. lead or steel.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Fishing Weights

- Details

- Category: Tungsten Information

- Published on Friday, 31 May 2013 15:10

- Hits: 2260

Tungsten alloy fishing weights are an ideal, environment-friendly alternative to lead weights, which are toxic and increasingly being labeled an environmental hazard. Tungsten alloy fishing weights are harder than steel and extremely dense, tungsten being on average 30 percent smaller than its lead counterpart. Tungsten alloy fishng weights are smaller than conventional weights, create twice the sound of lead weights and maintain their shape for longer. Tungsten is also used in the production of other fishing applications, such as tungsten-carbide line cutters and tungsten powder coating for fishing lines.

A fishing weight is a weight used to force a lure or bait to increase its rate of sink, anchoring ability, and/or casting distance. Fishing weights may be as small as 1/32 of an ounce for applications in shallow water, even smaller for fly fishing applications, or as large as several pounds or considerably more for deep sea fishing. They are formed into nearly innumerable shapes for diverse fishing applications. Environmental concerns surround the usage of most fishing sinker materials.

A jig is a type of fishing lure that usually consisting of a lead sinker with a hook molded into it and usually covered by a soft body to attract fish. However, recently, tungsten alloy fishing weights is becoming more and more popular among angles because it has the features of high density, small volume, and environmental friendly, and has been taking place of the lead sinker. Jigs are intended to create a jerky, vertical motion, as opposed to spinnerbaits which move through the water horizontally. The jig is very versatile and can be used in both salt water as well as fresh water. Many species are attracted to the lure which has made it popular amongst anglers for years.

The fishing weight is made by rare metal - Tungsten, it is an ideal substitute of the lead fishing sinker. It's strong adhesive, semi-solid state, soft for a long term. Tungsten Heavy Alloys concentrate maximum weight in the smallest possible space. They are more often to be used as counterweight in sporting field, such as fishing sinkers, golf weights, etc.

Advantages for tungsten alloy fishing weights

*Small body

*High density

*Nuisance free

*Strong wind resistance

*International environment protection standard

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

3D Printing Technology & Refractory Metal Material

- Details

- Category: Tungsten Information

- Published on Thursday, 30 May 2013 18:31

- Hits: 2419

Refractory metal is generally a kind of metal whose melting point is higher than 1650℃ and has definite reserves. The metals whose melting point is higher than Zr (1852℃) are also called as refractory metal. Refractory metal material is a kind of alloys which is based on refractory metal as matrix and add s with other metal elements. 3D printing technology is a kind of techniques which is based on files of mathematical model, utilizing refractory metal material and manufacturing substance by printing layer by layer. 3D printer appeared at the mid-term of 1990’s. It is a kind of rapid prototyping devices by using light-cure and paper stacking up. The operational principle is similar to general printer. There is refractory metal powder in 3D printer. When connecting with computer, the printer superimposes refractory metal material layer by layer, being controlled by computer. Lastly, the blueprint in computer will be change into material object. At present, 3D printing technology has been widely adopted in aviation industry for manufacturing main bearing components of fighter. The most outstanding advantage of 3D printing technology is that graphic data of computer can produce any shapes components directly, without machine work or moulds, so that can reduce lead time of product, improve productivity and lower cost.

s with other metal elements. 3D printing technology is a kind of techniques which is based on files of mathematical model, utilizing refractory metal material and manufacturing substance by printing layer by layer. 3D printer appeared at the mid-term of 1990’s. It is a kind of rapid prototyping devices by using light-cure and paper stacking up. The operational principle is similar to general printer. There is refractory metal powder in 3D printer. When connecting with computer, the printer superimposes refractory metal material layer by layer, being controlled by computer. Lastly, the blueprint in computer will be change into material object. At present, 3D printing technology has been widely adopted in aviation industry for manufacturing main bearing components of fighter. The most outstanding advantage of 3D printing technology is that graphic data of computer can produce any shapes components directly, without machine work or moulds, so that can reduce lead time of product, improve productivity and lower cost.

3D printing technology can not only be used for manufacturing plastic gun. At present, 3D printing technology has been widely used in developing and manufacturing of weapons around the world. Advanced 3D printing  technology can not only sinter or fuse plastic, wax and sand, it can also sinter refractory metal directly. In traditional manufacturing process of fighter, it needs long-term investment for manufacturing hydraulic forming equipment after finishing design of fighter 3D model. The processes of shaping and application of components have been improved largely while using 3D printing technology. The main bearing components, being made by refractory metal material and manufactured by 3D printing technology has been widely used for J-15, the first Chinese carrier aircraft, including the whole former landing chassis. It is said that the refractory metal material which is manufactured by 3D printing technology will be also used for J-20 and J-31, the fifth generation fighter.

technology can not only sinter or fuse plastic, wax and sand, it can also sinter refractory metal directly. In traditional manufacturing process of fighter, it needs long-term investment for manufacturing hydraulic forming equipment after finishing design of fighter 3D model. The processes of shaping and application of components have been improved largely while using 3D printing technology. The main bearing components, being made by refractory metal material and manufactured by 3D printing technology has been widely used for J-15, the first Chinese carrier aircraft, including the whole former landing chassis. It is said that the refractory metal material which is manufactured by 3D printing technology will be also used for J-20 and J-31, the fifth generation fighter.

3D printing technology can be also used for maintenance and guarantee of weapons in the battlefield directly. At present, the U.S. army has already deployed mobile laboratory in Afghanistan. The U.S. Army is also speeding up the combat deployment of 3D printing technology, so that can improve the maintenance ability of weapons and enhance persistent combat effectiveness during wartime. The damaged components can be printed by using 3D printing technology timely and assembled by maintenance personnel so that weapons can join in battle again.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Bio-medical Grade Tungsten heavy Alloys

- Details

- Category: Tungsten Information

- Published on Thursday, 30 May 2013 17:59

- Hits: 2410

Owing to its high density of shielding, tungsten heavy alloys is quite ideal for medical radiation shielding of which including Magnetic Resonance Imaging(MRI),Intensity Modulated Radiation Treatment(IMRT ),Positron Emission Tomography (PET), collimator, isotope container, and so on.

Tungsten heavy alloys for medical radiation shielding set forth below:

|

Designation |

Class/Grade |

Standard |

|

90W-7Ni-3Fe |

Class 1 |

AMS-T-21014 |

|

91W-6Ni-3Fe |

Class 1 |

AMS-T-21014 |

|

92W-5Ni-3Fe |

Class 2 |

AMS-T-21014 |

|

93W-4Ni-3Fe |

Class 2 |

AMS-T-21014 |

|

95W-3Ni-2Fe |

Class 3 |

AMS-T-21014 |

|

96W-3Ni-1Fe |

Class 3 |

AMS-T-21014 |

|

97W-2Ni-1Fe |

Class 4 |

AMS-T-21014 |

|

90W-6Ni-4Cu |

Class 1;Grade 1 |

MIL-T-21014;ASTM-B-459-67 |

|

90W-7Ni-3Fe |

Class 1;Grade 1 |

MIL-T-21014;ASTM-B-459-67 |

|

92.5W-5.25Ni-2.25Fe |

Class 2;Grade 2 |

MIL-T-21014;ASTM-B-459-67 |

|

95W-3.5Ni-1.5Cu |

Class 3;Grade 3 |

MIL-T-21014;ASTM-B-459-67 |

|

92.5W-3.5Ni-1.5Fe |

Class 3;Grade 3 |

MIL-T-21014;ASTM-B-459-67 |

|

97W-2.1Ni-0.9Fe |

Class 4;Grade 4 |

MIL-T-21014;ASTM-B-459-67 |

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Material for Shaped Charge Liners

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 May 2013 18:23

- Hits: 2466

The temperature of tungsten alloy material inside shaped charge liners rises from normal temperature to more than 1000℃ and strain rate reaches 1.0×105s-1. So, we can see that the shaping procedure of EFP (Explosively Formed Penetrator) is happening under the conditions of high temperature, high pressure and high strain rate. It is not any materials that can shape complete EFP. It has quite a high claims on the dynamic characteristics of materials under the condition of high temperature, high pressure and high strain rate. The ideal materials for shaped charge liners should have the properties of high melting temperature, high density, high elongation and dynamic strength, etc. Tungsten alloy material is ideal material for shape charged liners. Otherwise, engineering application also should considerate the cost and resources of material. Those materials which are important, high price and short resources are not easily utilized for a wide range.

Tungsten copper alloy shaped charge liners recombine metals which have different function so that can exert the complicated advantages of alloy. Compared with those single-metal shaped charge liners, tungsten copper alloy shaped charge liners have more reasonable transformation and absorption mechanism, more excellent penetration and lower cost. So it has wide prospect for development.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Heat Resistance Tungsten Alloy for Taihang Aero Engine

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 May 2013 15:12

- Hits: 2644

Heat resistance tungsten alloy is a kind of alloys which can work long term under the temperature more t han 600℃ and definite pressure. It has a series of complicated properties such as excellent hot strength, good anti oxidation and thermal corrosion resistance, good fatigue property and fracture toughness, etc. Heat resistance tungsten alloy has been the irreplaceable key materials for high-temperature components in military and civil gas turbine engine.

han 600℃ and definite pressure. It has a series of complicated properties such as excellent hot strength, good anti oxidation and thermal corrosion resistance, good fatigue property and fracture toughness, etc. Heat resistance tungsten alloy has been the irreplaceable key materials for high-temperature components in military and civil gas turbine engine.

The advancement of Taihang aero engine has close relationship with development of heat resistance tungsten alloy High turbine working temperature is the most significant symbol in Taihang aero engine. Improving turbine working temperature is an important measure to improve thrust and increase thrust weight ratio of Taihang aero engine. While the primary factor having influence on the temperature before engine turbine is materials of turbine blade and turntable which have high-temperature resistance. So designers of engine turbine components try their efforts to search a kind of high-temperature  resistance materials for turbine turntable and blade. Advanced heat resistance tungsten alloy satisfies with the need of aero engine for materials, and develops rapidly with the advancement of engine.

resistance materials for turbine turntable and blade. Advanced heat resistance tungsten alloy satisfies with the need of aero engine for materials, and develops rapidly with the advancement of engine.

Heat resistance tungsten alloy powder is a kind of heat resistance tungsten alloy It is indispensable key materials for advanced aero engine turbine turntable. For several years, heat resistance tungsten alloy powder had made great progress, and been utilized in turbine turntable and diversion turntable of Taihang aero engine. The realization of heat resistance tungsten alloy powder applications in aero engine reduces the gap with advanced technology of developed countries in this industry.

The development of Taihang aero engine, also called as WS-10 was begun at the end of 1980’s. The finalization of design was finished at December 28th, 2005 which had spent 18 years. Taihang aero engine is the first high-performance, high thrust, loading turbofan engine whose intellectual property right is owned by China. Meanwhile, it also fills the gap of advanced turbofan engine in China. Taihan aero engine is the third domestic military turbofan engine which is developed by China Aviation Research Institute 606. The maximum thrust of Taihang aero engine is not more than 12000kg, by adopting high thrust bypass ratio and fully automated digitized control system. At present, Taihang aero engine is mainly equipped in J-10 the third generation high performance fighters in China.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy EFP Projectile Flight Trajectory Model

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 May 2013 14:32

- Hits: 2396

Tungsten alloy is adopted as projectile for EFP (Explosively Formed Penetrator) with its high density, high intensity and high ductility. Terminal sensing submunition can detect and distinguish targets in scanning area. When scanning trajectory of terminal sensing submunition scans the target in scanning area, the computer on the penetrator detonates warhead of EFP duly, forming explosive compacting tungsten alloy EFP projectile and attacks armor vehicles from top. Tungsten alloy EFP projectile flight trajectory is the trajectory that EFP projectile flies to the target.

Tungsten alloy EFP projectile is influenced by gravity and air resistance during flying. Gravity bends tungsten alloy EFP projectile flight trajectory and air resistance decreases the flight speed of tungsten alloy EFP projectile. High density of tungsten alloy can weaken the influence on projectile caused by gravity and air resistance. High density means higher density of energy and greater impact force, improving penetrating power. High ductility contributes to forming longer projectile so that highly increasing the depth of penetration. Because the flight speed of EFP is faster than sound velocity by 5~6times, the distance from detonating to target is no more than caliber by 1000 times. For that, the influence on EFP flight trajectory by gravity can be neglected. So tungsten alloy EFP projectile flight trajectory can be considered as straight line trajectory approximately and also can be described by using equation of motion for particle.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Alloy Industrial Shielding Applications

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2013 18:32

- Hits: 2301

Tungsten alloy is used as collimator or radiation shielding in the following applications:

Geologging

Geologging is an exploration technique used mainly in the oil and gas industries. It is also known as wireline logging and borehole logging. A gamma ray source is lowered into a borehole and the radiation penetrates the rock strata. This data can then be analysed to determine whether deposits of gas or oil are present. Tungsten alloy is used to shield the radioactive source and to act as a collimator for the gamma beam.

Pipe-line Inspection

Gamma radiation is used to inspect welds and to detect cracks in pipelines. A gamma source is mounted on a remote-controlled wheeled trolley (sometimes called a "pig") and travels inside the length of the pipe. A tungsten collimator is used to direct the radiation onto the target, whilst the radioactive source is housed inside tungsten shielding.

Non Destructive Testing

Industrial radiography uses gamma radiation to detect structural faults in materials such as metal and concrete. As with pipe-line inspection, the equipment uses tungsten shielding, coupled with a tungsten collimator. Thickness, density and level gauging Radioactive sources are used in industrial processes to measure thickness, density or levels of materials during production e.g. paper, plastic film, steel sheet or surface coatings. The material passes between a radioactive source, which is housed in tungsten alloy, and a detector. The strength of the detector signal is used to measure the thickness, density or level of the material.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

How to Care for Your New Tungsten Ring?

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2013 18:14

- Hits: 2164

our new tungsten ring should last for a lifetime and always look great! There are a just a few points to keep in mind to ensure your ring stays in it's pristine condition for years to come.

Do not drop your ring on a hard surface or purposely hit it with hard metal tool, such as a hammer.

Do not clean your tungsten ring in a jewelers ultrasonic cleaner, or with a steam cleaner or ionic cleaner.

DO not clean your tungsten ring with any chemicals as this can cause spotting.

DO only clean your tungsten ring with a mild soap and water. This will remove dirt, grime, lotions and keep your ring sparkly clean!

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten-based Alloys in The Construction of National Defense and The Important Role of the National Economy

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2013 18:03

- Hits: 2137

In the aerospace industry applications. China developed the first generation of tungsten heavy alloy performance good in the 1960s, since immediately after the birth of self-developed China's first artificial satellite navigation device has been successfully applied, then this new material has the first in China an intercontinental missile and developed by a variety of new fighters, helicopters, has been successfully applied. Developed to meet the needs of Chinese communications satellite, but also successfully developed a new type of density up to 18.5g/cm3 high proportion of tungsten-based alloys. A variety of high-performance W-Cu alloys in the rocket (missile) combustion chamber, nozzle, throat, rudder and other parts of the development of high temperature has been applied.

Military industrial applications. China has successful developed the W-Ni-Fe heavy alloy, provides of a variety of wear, shaped charge of the development a key material. W-Ni-Cu heavy alloys also play an important role in doing gyrorotor high proportion of material in China's first nuclear submarine of the research and development.

In the civilian industry and nuclear industrial applications. In the nuclear power industry, used for nuclear reactor insulation and shielding materials, tungsten heavy alloy has a good prospect. In civilian industry, high-density tungsten alloy has been more widely used; mobile phones and golf oscillator rod weight will be a wide range of products. Processing done in the electric performance of the anvil block material to make electrical upsetting of hundredfold increase production efficiency, has significant economic benefits.

In summary, the development of tungsten processing industry does not only play a very important role in building on the national economy, also has a significant impact on the modernization of national defense.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com