High Jump Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 15:53

- Written by yingying

- Hits: 602

High Jump tungsten dart rule is a very unique style of game similar only to it's cousin, Broad Jump. It may be played by any number of players or teams and is a good game to play with an odd number of people.

The Object: The object of the game is to "jump" higher than your opponents.

The Scoring: Players names are written in order down the left side of the scoreboard. Order is usually determined by throwing one dart each at bulls-eye. Closest to the bulls-eye throws first, farthest throws last.

The Play: Each player in turn throws three darts trying to advance the target numbers to make the highest "jump". The targets are up the center of the board in order: Double-3, Large-3, Triple-3, Small-3, Bulls-eye, Double-Bulls eye, Bulls-eye, Small-20, Triple-20, Large-20, Double-20.

For a dart to count, the targets must be hit in order, one dart each. Play begins with the Double-3, once the Double-3 is hit the player may now throw at Large-3 and so on across the board.

After the each player throws all three darts, the "highest" target that was hit becomes the height of the jump and is written next to the player's name and play continues with the next player. The next time that player throws again, the target number is the next number after the old target. This means that each round extends the height of the jump for that player.

If the player misses the target with all three darts, that player's jump is over and the last target that was hit becomes the final height of the jump. That player does not throw again.

After all players have missed their target with three darts, whoever's jump was highest wins the game. If more than one player has the same height jump at the end of the game or both made it all the way across the board, those players alone should play again to break the tie.

Strategy: Take your time and concentrate when you get to the bulls-eye area. They are hard to hit, but if you get past them, it's all down hill from there.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Decorating Tungsten Dart Flights

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 15:50

- Written by yingying

- Hits: 323

Tungsten dart flights stabilize a tungsten dart throw differently depending on their shape, size and texture. Creating your own tungsten dart fights allows you to personalize your tungsten darts to your own preferences and style of dart throwing. You can choose the material, texture and design of your flights to express yourself and to give yourself a leg up on the competition. Making your own flights also gives you greater control over the feel of your tungsten darts.

Decorating the Tungsten Dart Flights:

1. Trace the flight template two times onto a plastic sheet with a pen.

2. Cut out both flights with a utility knife.

3. Draw your design on both flights.

4. Cut a thin, rectangular slit halfway up the first flight. Begin cutting at the bottom of the flight.

5. Cut a thin, horizontal slit halfway down the second flight. Begin cutting at the top of the flight.

6. Slide the two slits together to interlock the flights.

7. Line up the flights along the slits so that tops and bottoms connect exactly.

8. Glue the flights together along the seam.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Create Template of Tungsten Dart Flights

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 15:48

- Written by yingying

- Hits: 646

Tungsten dart flights stabilize a dart throw differently depending on their shape, size and texture. Creating your own tungsten dart fights allows you to personalize your tungsten darts to your own preferences and style of dart throwing. You can choose the material, texture and design of your flights to express yourself and to give yourself a leg up on the competition. Making your own flights also gives you greater control over the feel of your tungsten darts.

Creating a template of Tungsten dart flights:

1. Cut a 2-inch-by-2-inch square from a piece of paper.

2. Fold the paper square to create diagonal and horizontal crease lines across the paper.

3. Open the paper square.

4. Create the tungsten dart flight's basic shape. To do this, bring the center points of all the edges together, folding the paper along the previously made crease marks. Lay the flaps flat, creating an upside down triangle.

5. Cut the top tips of the triangle to give your flight a modern look. Traditional shapes for tungsten darts are the kite, the pear and the slim. Cut off the triangle's top tips to make a diamond kite shape. Round the triangle's top tips for the pear shape, and cut the triangle's outside edges to slim the flight.

6. Open the square paper.

7. Cut the square paper along both diagonal creases. This will create four flight templates. Only one is needed for a template.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nine Lives Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 15:45

- Written by yingying

- Hits: 363

Nine Lives tungsten dart rule is a simple game of elimination for any number of players. It does get a little long when there are a lot of players, however.

The Object: To be the first player to get "around the clock", that is to get at least one tungsten dart in each number from 1 through 20 in order.

The Scoring: Each player throws one tungsten dart at bulls-eye, closest to the bulls-eye goes first, furthest from the bulls-eye goes last. Each player gets three "lives" represented by three tally marks below their name. No, I don't know why they call the game 9 lives but you only get 3. Maybe it was invented with 3 players?

The Play: Each player takes a turn trying to hit each number from 1 through 20. The numbers must be hit in order or they do not count.

If a player misses with all three tungsten darts, one life is lost (a tally mark is erased) from that player. When all three of a players lives are lost, that player is out of the game.

The winner of the game is the first player to make it to 20 or the last player in the game to have any lives left.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pure tungsten electrode - Ⅲ

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 14:59

- Written by Yahong

- Hits: 327

Pure tungsten electrode (model - L10) common specification

|

Model |

Content |

Length/mm |

Diameter/mm |

Welding materials |

|

L10 |

La2O3, Y2O3, CeO2 The rest: tungsten |

150/175 |

0.5 |

Copper/ Aluminum / Carbon steel/ Stainless steel |

|

150/175 |

1.0 |

|||

|

150/175 |

1.6 |

|||

|

150/175 |

2.0 |

|||

|

150/175 |

2.4 |

|||

|

150/175 |

3.0 |

|||

|

150/175 |

3.2 |

|||

|

150/175 |

4.0 |

|||

|

150/175 |

4.8 |

|||

|

150/175 |

5.0 |

|||

|

150/175 |

6.0 |

|||

|

150/175 |

7.0 |

|||

|

150/175 |

8.0 |

|||

|

150/175 |

10.0 |

|||

|

150/175 |

12.0 |

Package:

10 / plastic box; Length: 150mm / 175mm; 1000 / carton.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pure tungsten electrode -Ⅱ

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 14:53

- Written by Yahong

- Hits: 338

Pure tungsten electrode is the earliest electrode used in arc welding technology.

TIG technology refers to the welding method under the function of protective gas-argon gas, that is to say, it is a technology that inlet the argon gas as a protective gas around the arc welding, isolate the air outside the welding areas to prevent the oxidation of welding material, which is also known as argon arc welding, can be used to weld metal hardware, stainless steel and other materials.

Arc welding refers to the process that using the heat generated by arc combustion (i.e., arc discharge) to make welding electrode (or welding wire) smelting with workpiece and condensation, then it will form the weld, and then a solid workpiece can be obtained, in industrial production, this method has the most wide application.

Pure tungsten electrode owns good conductivity, small thermal expansion coefficient, low resistance, low vapor pressure and high elastic modulus and other excellent performance.

Today, with the economic development, the world annual demand for the tungsten electrode is still in a growing trend. China's annual output of tungsten electrode has been growing steadily, accounting for about 3/4 of the world production of tungsten electrodes.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Pure tungsten electrode -Ⅰ

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 14:51

- Written by Yahong

- Hits: 307

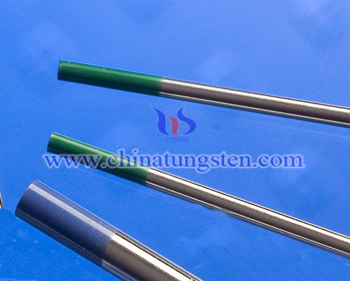

The content of tungsten in pure tungsten electrode is higher than 99.5%, and there are no other alloying elements existing. Compared to other tungsten alloy electrode, such as, tungsten copper electrode, silver tungsten electrode and tungsten nickel electrode, etc., because pure tungsten has high electronic work function, so its arc is more difficult than tungsten alloy electrode, and it is also difficult to maintain the stability of the arc beam. It’s the tip temperature of the electrode is relatively high, it will make the grain easy to grow, and the arc beam will be instable, leading to harder arcing, and shorter service life (improvement method: adding rare earth oxides). Therefore, tungsten is only used for AC welding.

Arc, as the name suggests, it is the process that the welding material (welding wires, welding rods, etc.) ignite the arc process.

Basic index of pure tungsten electrode

|

Grade |

Color |

Other impurities/% |

Tungsten/% |

Doping content/% |

Electronic work function/ eV |

|

WP |

Green |

<0.20 |

The rest |

--- |

4.5 |

Electronic work function refers to the electronic break the bound of the nucleus, the minimum energy needed to escape from the surface of the material.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Electrode (Pure Tungsten Electrode) Species and Application

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 14:49

- Written by Yahong

- Hits: 309

Pure tungsten electrode is one species of tungsten electrode, the species of tungsten electrode and its application

|

Tungsten electrode species |

Grade |

Color sign |

Application |

|

Thorium tungsten electrode |

WT20 |

red |

It has the most widely application, mainly for the welding of titanium, copper, carbon steel, stainless steel and other materials (with slight radioactivity) |

|

Cerium tungsten electrode |

WC20 |

grey |

It is mostly used in low current DC conditions, mainly applied in carbon steel, copper, titanium, stainless steel, etc. |

|

Pure tungsten electrode |

WP |

green |

It is mainly used for welding aluminum, magnesium, aluminum alloy, magnesium alloy, etc. (its welding conditions requirement is relatively lower) |

|

zirconium tungsten electrode |

WZ8 |

white |

It is mainly employed in the welding of aluminum and aluminum alloys |

|

Yttrium tungsten electrode |

WY |

blue |

It is mainly used in military and aerospace

|

|

Silver tungsten electrode |

- |

- |

It is mainly used in aerospace, metallurgy, high temperature resistance materials and microelectronics,etc. |

|

Composite tungsten electrode |

WRex |

- |

It is mainly applied in metallurgy, machinery and so on.

|

|

Lanthanum tungsten electrode |

WL20/ WL15/ WL10 |

gold / sky blue / black |

It has a wide range of applications, and mainly used for welding copper, aluminum, aluminum alloy, carbon steel, stainless steel, titanium, etc. |

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Pulsed Nozzle

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 17:59

- Written by xiaobin

- Hits: 362

Compared with common nozzle, tungsten carbide pulsed nozzle can accelerate 10%-77% at speed in drilling and deepen 10%-48% in depth of drilling, which definitely improves oil field drilling and brings about financial benefits. Because the chamber of pulsed nozzle is bigger than the entrance and exit, using traditional methods can not suppress sintering powder metallurgy so that we should take advantage of powder metallurgy principle, no needs welding processing, and the product as a whole, duration will be highly improved.

Its principle is the flow runs into chamber and via two upper and lower reflecting surfaces , the upper surface reflecting pressure wave is equal to the lower movement of the pressure wave phase, and comes into addition of waveforms. And the circle shearing stress is forming water bombs in vacuum, where generated in the high-pressure, high velocity water bombs discharged form a discontinuous flow of the water ejection, continuous power to overcome the shortcomings of the existing continuous small-jet nozzle, and improve the instantaneous impact force of the jet spray distance and the effective energy of the flow reaches the bottom of well.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Solid-cone Nozzle

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 August 2015 17:57

- Written by xiaobin

- Hits: 363

The atomization of tungsten carbide nozzle distributes on average, the angle of jet is 30° - 120°, and the drop arrayed by size in ascending order. Owing to its special design of vane, which is suitable for some area requires covered by atomization, the system can be control precisely. Its sustaining flow is 0L/min - 1000L/min, common sizes are 1/8inch, 3/8inch, 1/4inch, 3/4inch, 1/2inch, 1inch, 1.5inch, 2inch, 3inch, pressure is 0MPa – 15MPa, and has several modes such as external thread connection, internal thread connection, ferrule fitting connection, folder connection, welding solution and flange form connection, etc. Therefore, it can be widely used in surface solutions like the phosphorization metal parts, high pressure cleaning, PCB cleaning, cooling and so on.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com