Cerium Tungsten Electrode -Ⅱ

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 18:03

- Written by Yahong

- Hits: 313

In the early 1980s, cerium tungsten electrode was used as a non-radioactive tungsten electrode in place of thorium tungsten electrode, and was introduced to the United States. Under normal circumstances, the content of CeO2 in cerium tungsten electrode is about 2%. In the low voltage conditions, because cerium tungsten electrode can easily arc at a low voltage, so it is suitable for DC welding. The best selection of tungsten electrode is thorium or lanthanum tungsten electrode when you welding at high voltage or high current conditions. Because of in AC welding condition, the Cerium tungsten electrode will easily split. Cerium tungsten electrode has a lower rate of evaporation and combustion rate than pure tungsten electrode. With the increase of CeO2 content, these advantages are gradually revealed.

Cerium tungsten electrode advantages:

1. It owns excellent performance of tungsten;

2. It is the best products at low current condition, such as, tiny or complex parts welding.

3. No radiation, it can operate at low currents, and has a low melting rate and longer life.

4. It cathode spots are small, the pressure drop is small, does not burn, and it is widely used in arc welding.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cerium Tungsten Electrode - Ⅰ

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 18:00

- Written by Yahong

- Hits: 342

Cerium tungsten electrode is a kind of tungsten electrode without radioactivity. It can be used to take place of thorium tungsten electrode (with radioactivity) when its diameter is less than 2.0mm or when it is in a low-current DC condition, it can be used in place of thorium tungsten electrodes (radioactive); thanks to its good advantages, such as, good arc starting performance and smaller pilot arc current, it can be applied for the welding of stainless steel parts, pipes and small precision parts; adding rare earth cerium oxide (CeO2) to tungsten, prepared it by powder metallurgy process to get tungsten electrode products.

Cerium tungsten electrode (adding cerium oxide - CeO2to the tungsten) grade and standard

|

Grade |

Color sign |

Other impurities% |

Tungsten% |

dopant |

Doping amount % |

Electronic work function/ eV |

|

WC20 |

Grey |

<0.20 |

The rest |

CeO2 |

1.80-2.20 |

2.7-2.8 |

Specification

Length (mm): 150/175, and the like;

Diameter (mm): 0.5 / 1.0 / 1.6 / 2.0 / 2.4 / 3. / 3.2 / 4.0 / 4.8 / 5.0 / 6.0 / 7.0 / 8.0 / 10.0 / 12.0, and so on;

Welding materials: copper, aluminum, carbon steel and stainless steel and so on.

Package

10 / plastic box; Length: 150mm / 175mm; 1000 / carton.

Application

It can be used for AC / DC welding, especially in the small current conditions.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Radiation Shielding Efficiency of Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:38

- Written by wenjing

- Hits: 413

Tungsten alloy is a tungsten-group sintered alloy consisting of tungsten and a binder phase with nickel, copper, iron, etc. Tungsten alloy is also used as radiation shielding material because of its excellent radiation shielding effect realized by its high density. Recently, due to environmental requirements, Tungsten alloy has attracted attention as replacement for lead which has been used for this application.

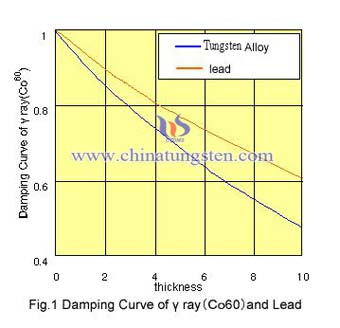

On the radiation shielding effect of tungsten alloy, we examined a comparative evaluation with lead. Fig.1 shows the attenuation rate of γ-ray (Co60) against the change in thickness of tungsten alloy and lead. The γ-ray (Co60) used for the evaluation this time is that eradiated from relatively a high energy zone, which becomes an issue in the case of nuclear power station.

This evaluation proves that tungsten alloy of about 3mm or 7mm thickness has the radiation shielding effect equivalent to lead of about 4.5mm or 10mm thickness respectively. consequently, tungsten alloy, compared with lead, has 1.5 times shielding effect against γ-ray (Co60).

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Tungsten Isotope Radiation Container

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:36

- Written by wenjing

- Hits: 432

Radioactive isotope called "radioisotopes." Isotope radiation technology now widely used in industry, agriculture, health, archeology, and environmental protection and other aspects, including radiation detectors, radiotherapy apparatus and medical X-ray instruments. The most important component of radiation technology equipment is the radiation shielding container. When using radiation technology, place radioactive isotope within the shielding container is the most important thing. Due to its high density, excellent absorption behaviour against radiation and environmental friendly characteristics, tungsten material can be widely used to produce isotope radiation container.

Applications of tungsten isotope radiation container:

Industrial instrumentation equipment and petroleum drilling

Cancer treatment equipment

Weld inspection

Large container inspection equipment

Nuclear submarine accessories

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Process Test of Copper-Bismuth Separation from Sulfide Minerals Associated With Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:21

- Written by xinyi

- Hits: 350

This paper studies the process test of copper-bismuth separation from sulfide minerals associated with tungsten ore by applying the combined process of gravity separation,flotation and gravity separation.The results of small closed-circuit test: the copper concentrate with the grade of 25.03 % and the recovery of 93.93 %;the bismuth loss rate in the copper concentrate is 7.08 %;the bismuth concentrate with the grade of 15.08 % and the recovery of 79.42 %;the copper loss rate in the bismuth concentrate is 1.84 %.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sodium Polytingstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:17

- Written by xiaoshan

- Hits: 348

Sodium polytingstate are also known as sodium metatungstat. Its physical properties are as follows: chemical formula: Na6O39W12, molecular weight: 2968, density: 3.1g/cm3, CB number: CB1128947, CAS number: 12141-67-2.

Sodium Polytingstate because of its high density, non-toxic, easy preparation and can be recycled and other advantages so it has been widely use in many areas. For example sodium polytingstate wildly use in density separation research area of geology, soil science and marine biology. In geology it is mainly used in separation minerals and sedimentary rocks, for the separation of micro-fine pure minerals providing a new way. In soil science it is mainly used in separate large particles of soil aggregates, organic matter and humic acid and so on. In marine biology and is mainly used in the separation of ancient microbial and organic matter. On the other hand, using sodium polytingstate solution to density separation the operation is simple and the effect is stable. What’s more it not changes the physical and chemical properties of substances to be separated.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Simulation and Analysis on Flow Field in Leaching Tank With Dual-impeller for Alkali Cooking Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:14

- Written by xinyi

- Hits: 346

Simulation and Analysis on Flow Field in Leaching Tank With Dual-impeller for Alkali Cooking Tungsten Ore

Computational fluid dynamics method was applied to study three-dimensional flow field in leaching tank with JH type axial impeller and straight blade impeller.The velocity field,pressure field and turbulent kinetic energy field in leaching tank were analysized rotating at constant speed of 300 r/min and taking the fluid of sodium hydroxide mixed with tungsten ore as simulation object by using the multi-reference frame(MRF) and standard k-ε turbulent model.The research provided scientific basis for structure optimization design of leaching tank.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preliminary Isotope Studies of the Lianhuashan Tungsten Ore Deposit

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 17:08

- Written by xinyi

- Hits: 348

Lianhuashan deposit, the first porphyry-type tungsten deposit ever discovered in China, is located in the east of Guangdong Province. Stratigraphically only Jurassic Xiaoping coal series and acidic volcanic rocks occur in the mining area with the latter unconformably overlying the former. Biotite granite, quartz-porphyry and quartz diorite-porphyrite constitute the major intrusives. Rb-Sr isochron ages of the volcanic rocks and the granite are 135.8 ±2.5 m. y. and 137.2± 2.5 m.y. respectively, indicating that they are products of the identical magmatic activity. K-Ar apparent ages vary between 76.6 m.y. and 119.5 m.y. with the K~(40)-Ar~(40) isochron age of volcanic rocks determined at 120.4±12.1 m.y. These ages are as a rule younger than the corresponding Rb-Sr ages. The formation of ferberite-bearing greisen represents the first stage of tungsten mineralization. The K-Ar age of its muscovite is 119.5 m.y., denoting the coincidence of the tungsten mineralization with the igneous rocks in their formation time. The younger K-Ar apparent ages of samples from this area might be chiefly attributed to the effect of the late stage thermal events in the mega-metallogenic belt around the Pacific Ocean. The stable isotope measurements give the following δS~(34)(‰) values:pyrrhotite, from -0.05 to + 3.14;pyrite, from -0.85 to + 3.3; total sulfur(δS_(ΣS)~(34)), 2.0, suggesting that sulfur in the deposits came from deep sources. Initial ratios of Sr isotopes for volcanic rocks and granitic rocks are 0.7061 ±0.0004 and 0.7069 ±0.006 respectively, showing that, in addition of occurring in the same period, they were derived from the same sources. The materials for igneous rocks and tungsten deposits were probably formed as a result of the melting of the oceanic plate along the subduction zone.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

On the Response of Magma Activity and Mineralization of Shirenzhang Tungsten Ore in East China's Yanshan Geological Period

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 16:59

- Written by xinyi

- Hits: 347

The most extensive magma activity and mineralization in Shirenzhang zone occurred in Yanshan Period,which is also the most important mineralization term in East China.The magma activity and mineralization of Shirenzhang region in Yanshan geological period must be restricted by the bigger tectonic environment of East China.In another word,the magma activity and mineralization of Shirenzhang zone in Yanshan period is a reflection of magma activity and mineralization of Shirenzhang zone in East China.This paper tries to talk about the tectonic-magma-mineralization of Shirenzhang zone in a bigger environment of East China.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Dartboard Setup Tips

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 August 2015 15:55

- Written by yingying

- Hits: 373

dartboard setup tips:

1. Setup your dartboard in a safe and secure area that is wide enough for people to stand around while waiting to play. An area with at least a meter on both sides of the dartboard should be wide and safe enough to prevent anyone from getting hurt if any darts should bounce-out.

2. The area should preferably have a carpet or wooden floor. Tile floors, cement or anything similar will damage the darts that bounce-out. It is a good idea to place a dart mat directly below the dartboard on any type of floor. A dart mat will protect your darts and will save you time to install an oche(throwing-line), because dart mats are completely marked for this purpose else any normal piece of carpet will do.

3. The area must be well lit or contain / be able to hold the necessary fixtures to provide adequate lighting to the dartboard.

4. It is a good idea to place the dartboard in a dartboard cabinet. A cabinet will protect the wall and will save you time to put up scoreboard/s.

5. If a dartboard cabinet is not used, erect a scoreboard on one or both sides of the dartboard, where it is easy visible.

6. If a dartboard cabinet is not used, it is a good idea to place a wooden board or some kind of protection behind the dartboard to protect your darts and the wall should someone miss when throwing at the dartboard.

7. Make absolutely sure that all dartboard setup measurements are 100% accurately. Once you get use to the throwing distance and height, you can immediately feel it if someone else’s measurements are not the same and it will influence your throwing and vice verse.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com