Tungsten Concentrate Gravity Separation – Ball Mill

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 July 2017 17:04

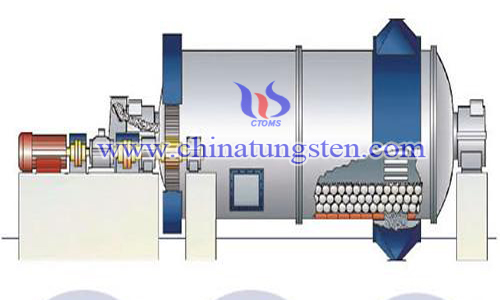

After artificial beneficiation, tungsten concentrate will enter gravity separation. In grinding and tungsten slime recovery process need fine grinding, the equipment is ball mill.

As we all know, after jigging separation, the high grade ore is separated, the rest part still contains tungsten element and need to use gravity separation, flotation, magnetic separation and electric separation to extract them. To do the subsequent process easily, the rest tailings shall be grinded again, the ball mill is needed. Usually grain size is smaller than 2mm and bigger than 0.037mm.

At present, wet overflow ball mill is more often used, its main component is cylinder with small diameter and large length, supported by rolling bearings, rotate through the transmission machinery, the material is sent from the cylinder feed end into cylinder. Due to the ball and the ore itself throwing the impact and self-grinding, the material can be crushed. Due to the continuous feeding of materials, the pressure will promote the material move from the feed end to the discharge end of the material. The lower edge of the hollow shaft will flow out, hollow shaft with anti-spiral blade can return the overflow of steel balls and rough to the mill.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com