Tungsten Carbide Inserts’ Wear Mechanisms in Green Oak Machining

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2015 14:17

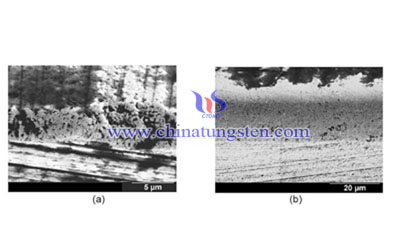

When using tungsten carbide inserts in green oak machining, some typical degradation would be identified by examining its wear mechanisms.

There is no attack occurred between tungsten carbide grains and the extractives when the cobalt binder is removed from the interstices. Some researchers suggested that the depth of the cobalt binder is removed, is of the order of the tungsten carbide grain size at any stage in the life of a tool. It also suggested that wear occurs primarily by preferential dissolution of the binder phase though chemical attack by the extractives present in the Oak which is then followed by loss of individual carbide grains when the strength of the remaining WC-Co-bond is insufficient to resist action of the shear forces caused by motion of chip and wood over the tool face. This motion would, in addition, be responsible for removing any corrosion reaction products which may form during cutting. Such a mechanism is fundamentally different to that which usually occurs in metal cutting.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com