Why Is Tungsten Disulfide Compounded with Carbon Nanotubes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:25

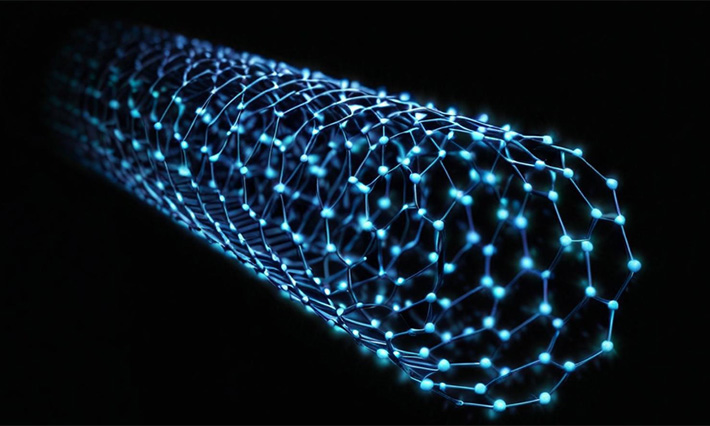

The combination of tungsten disulfide (WS₂) and carbon nanotubes (CNTs) primarily aims to leverage the strengths of both materials, achieving complementary and synergistic enhancements in performance to meet the demands of various applications. For instance, in reactions such as hydrogenation and hydrogen evolution, WS₂-CNT composites exhibit superior catalytic performance compared to their inpidual components, showing great potential for widespread use in energy conversion and chemical industries. Additionally, due to their excellent electrical properties and high specific surface area, WS₂-CNT composites can be utilized to fabricate high-performance gas sensors, biosensors, and more.

The main reasons for combining tungsten disulfide with carbon nanotubes are as follows:

1. Enhancing Mechanical Properties

Improved Toughness: Tungsten disulfide, a layered structure material, has weak interlayer bonding, making it prone to interlayer sliding under external forces, which results in poor toughness. CNTs, with their exceptional strength and toughness, possess a unique one-dimensional nanostructure that acts as a bridge and support between WS₂ layers. This effectively prevents interlayer sliding in WS₂, significantly enhancing the toughness of the composite material.

Increased Hardness and Wear Resistance: The high hardness and wear resistance of CNTs compensate for the shortcomings of WS₂ in these aspects. When CNTs are uniformly dispersed in the WS₂ matrix, they increase the surface hardness of the material, improving its resistance to friction and wear, thus extending its service life. For example, in applications requiring wear-resistant coatings, WS₂-CNT composites offer better wear protection than pure WS₂ coatings.

2. Optimizing Electrical Properties

Enhanced Conductivity: Although tungsten disulfide possesses certain electrical properties, its conductivity is still limited compared to high-performance conductive materials. CNTs, with their excellent conductivity due to their unique electronic structure, enable rapid electron transport within their tubes. When combined with WS₂, CNTs form efficient conductive pathways within the WS₂ matrix, facilitating electron mobility and significantly improving the overall conductivity of the composite. This is particularly crucial for applications of WS₂ in electronic devices and electrode materials, enhancing device performance and response speed.

Bandgap Tuning: The combination of CNTs and WS₂ can also influence the bandgap structure of WS₂. By adjusting the content and distribution of CNTs, the bandgap of the composite can be precisely tuned, allowing for fine control over its electrical properties. For instance, in optoelectronic devices, this bandgap adjustment can enhance the material’s absorption and response to specific wavelengths of light, improving the photoelectric conversion efficiency.

3. Improving Electrochemical Performance

Increased Specific Surface Area: In energy storage applications, such as lithium-ion batteries and supercapacitors, the specific surface area of a material significantly affects its electrochemical performance. CNTs, with their high specific surface area, provide more active sites for electrochemical reactions. When combined with WS₂, the composite not only exhibits an increased specific surface area but also improves contact between the electrode material and the electrolyte, facilitating ion transport and adsorption. This enhances the charge-discharge efficiency and specific capacity of batteries.

Enhanced Cycling Stability: Tungsten disulfide tends to undergo volume changes during charge-discharge cycles, leading to structural instability and reduced battery cycle life. The incorporation of CNTs can mitigate these volume changes in WS₂ while their excellent conductivity helps maintain the structural integrity of the electrode. This improves the cycling stability of the composite material. For example, in lithium-ion batteries, WS₂-CNT composite electrodes can maintain high specific capacity and good charge-discharge performance even after multiple cycles.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com