Why Is Tungsten Disulfide Compounded with Graphene?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:33

The composite of tungsten disulfide (WS₂) and graphene is a significant research direction in materials science. By combining the strengths of both materials, a synergistic effect is achieved, endowing the composite with exceptional properties such as enhanced catalytic and electrochemical performance.

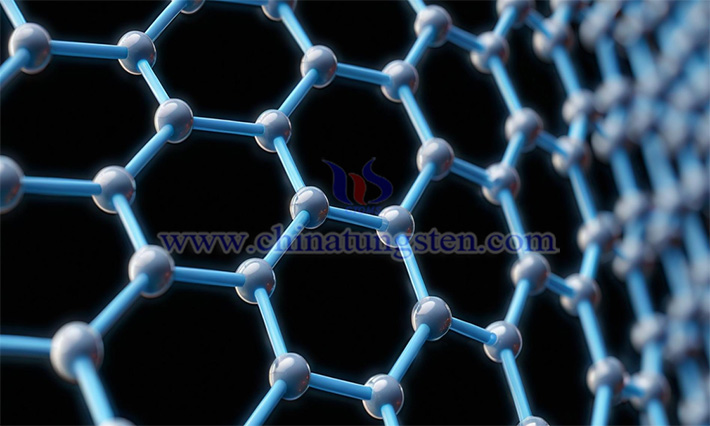

Both WS₂ from CTIA GROUP LTD and graphene are quintessential two-dimensional (2D) materials. Graphene is a 2D carbon nanomaterial composed of carbon atoms arranged in a hexagonal honeycomb lattice via sp² hybridized orbitals, renowned for its outstanding mechanical and electrical properties. WS₂, on the other hand, features a sandwich-like layered structure, with tungsten and sulfur atoms bonded covalently within layers and held together by van der Waals forces between layers. The 2D nature of both materials allows them to integrate seamlessly during composite formation, creating a stable structure that maximizes their synergistic potential.

1. Enhancing Electrical Properties

Formation of Efficient Conductive Networks: Graphene’s high conductivity enables the creation of efficient electron transport pathways within WS₂. When combined, electrons can rapidly transfer between graphene and WS₂, significantly boosting the overall conductivity of the composite. This enhancement is critical for improving the electrical performance of materials in electronic devices, such as transistors and electrode materials, by reducing resistance, increasing electron mobility, and thereby enhancing device performance and operational speed.

Bandgap Tuning: The interaction between graphene and WS₂ in the composite alters the bandgap structure of WS₂. By controlling the preparation process and the ratio of the two components, the bandgap can be precisely tuned to meet the specific requirements of various electronic devices. For instance, in optoelectronic applications, an optimized bandgap enhances the material’s absorption and emission properties for specific wavelengths of light, improving photoelectric conversion efficiency.

2. Improving Mechanical Properties

Enhanced Mechanical Strength: Graphene, often hailed as the “king of new materials,” possesses exceptional strength and modulus. When combined with WS₂, graphene acts like “nanoscale reinforcement bars” distributed between or on the surfaces of WS₂ layers, effectively preventing interlayer sliding and crack propagation. This significantly enhances the mechanical strength and toughness of the composite. Such reinforcement is highly valuable in producing high-performance composite coatings and films, improving wear resistance, fatigue resistance, and other mechanical properties, thereby extending the material’s service life.

Increased Flexibility: The layered structure of WS₂ somewhat limits its flexibility, whereas graphene exhibits excellent flexibility. Upon compositing, graphene imparts greater flexibility to WS₂, enabling the composite to maintain robust performance under bending or folding conditions. This is particularly crucial for applications in wearable devices and flexible electronics.

3. Boosting Electrochemical Performance

Increased Active Sites: In energy storage and conversion applications, such as lithium-ion batteries and supercapacitors, a material’s electrochemical performance is closely tied to the number of active sites. Graphene’s high specific surface area provides abundant active sites for electrochemical reactions while facilitating thorough contact between the electrolyte and the material. When combined with WS₂, their synergistic interaction further increases the number of active sites in the composite, promoting lithium-ion insertion and extraction, and thereby enhancing battery specific capacity and charge-discharge efficiency.

Improved Cycling Stability: WS₂ tends to undergo volume changes and structural degradation during charge-discharge cycles, compromising its cycling stability. The presence of graphene mitigates these volume changes in WS₂, while its excellent conductivity helps maintain the structural integrity of the electrode. This improves the cycling stability of the composite. For example, in lithium-ion batteries, WS₂-graphene composite electrodes retain high specific capacity and reliable charge-discharge performance even after multiple cycles, demonstrating promising application potential.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com