Packaging for High-Cut Resistance Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:09

The packaging of high-cut resistance tungsten wire (i.e., tungsten wire with high resistance to cutting) is typically designed based on its application, transportation requirements, and material properties to ensure safety and integrity. Tungsten wire itself is a high-hardness, high-melting-point metal material widely used in industrial cutting, electronic devices, and high-temperature environments. Therefore, its packaging must not only protect the wire from external damage but also facilitate storage and usage.

Generally, the packaging of high-cut resistance tungsten wire may include the following features:

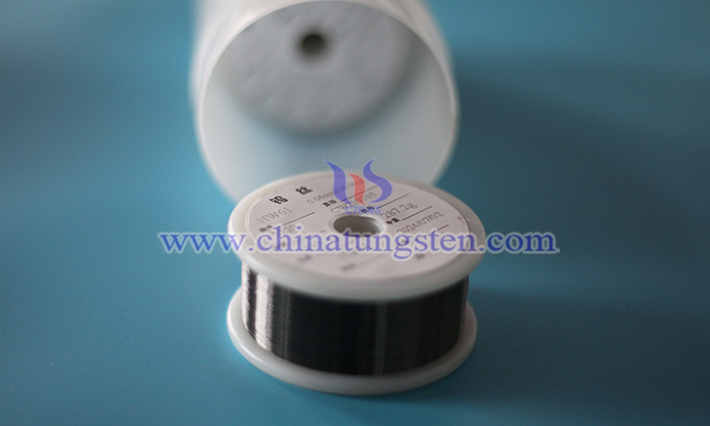

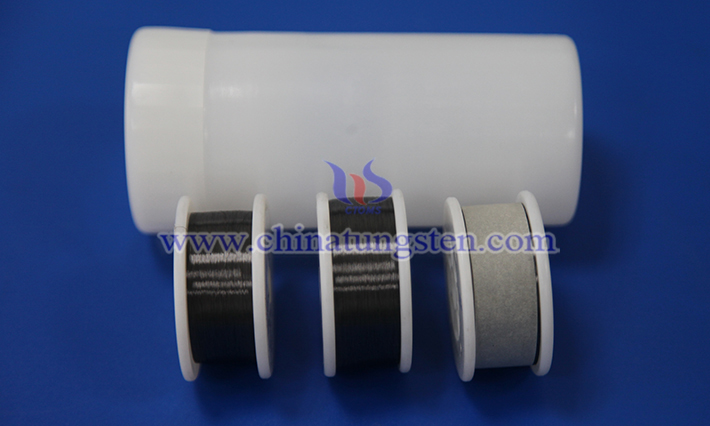

1. Protective Packaging: As tungsten wire may be thin and susceptible to bending or breaking from external forces, the packaging usually employs sturdy materials such as plastic reels, cardboard boxes, or metal containers to secure the wire and prevent damage during transportation. Reel-type packaging is particularly common, as it facilitates winding of the thin wire and prevents tangling.

2. Customized Specifications: Depending on the diameter (e.g., 0.1mm or thinner) and length of the tungsten wire, the packaging is labeled with specific specifications. Some suppliers (e.g., Zhongnuo New Materials) offer customized services, where the packaging quantity and format can be adjusted according to customer needs.

3. Moisture and Oxidation Resistance: In certain cases, tungsten wire may be sensitive to moisture or oxidation. Therefore, the packaging may include sealed plastic bags or incorporate desiccants to prolong storage life.

4. Transportation Convenience: For large quantities of tungsten wire used in industrial applications, the packaging may utilize pallets or wooden boxes to ensure stability during long-distance transportation. Lightweight packaging materials may also be used to reduce transportation costs.

5. Clear Identification: The outer packaging is usually printed with product information such as purity (commonly 99.99%), diameter, weight, etc., for easy identification and usage by customers. Additionally, transportation warning labels such as "fragile," "avoid magnetization," and "no heavy pressure" are added based on the specific product characteristics.

CTIA GROUP provides tungsten wire packaging that balances protective performance, transportation safety, and industry standards. If you have specific usage scenarios or require more detailed information, please contact us at sales@chinatungsten.com.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com