Structure and Morphology of Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Thursday, 24 February 2022 21:54

The research team at Yingkou Institute of Technology and Georgia Institute of Technology recently presented their latest work describing the structure and antimicrobial properties of thin-film coatings based on tungsten oxide materials on stainless steel substrates.

Tungsten (VI) oxide, also known as tungsten trioxide or tungstic anhydride, WO3, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals. Tungsten ores are treated with alkalis to produce WO3. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to pure metal.

In recent decades, tungsten oxide (WO3-X), one of the most important transition metal oxides, has attracted great interest due to its wide application in various unique technological fields. In general, WO3 films are prepared by various methods such as pulsed laser deposition, thermal evaporation, sputtering, chemical vapor deposition, spray deposition, spin coating, sol-gel spin coating, and electrodeposition.

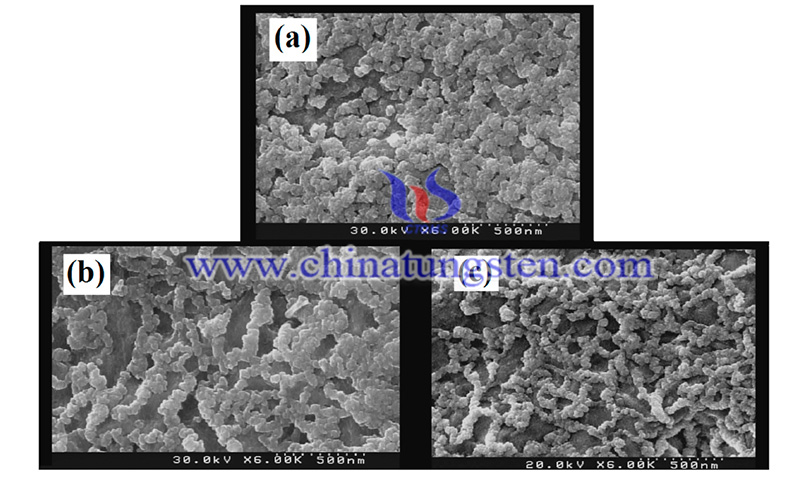

The films were prepared by RF magnetron sputtering of W targets in an oxygen/argon plasma environment with a sputtering power of 60 W. As we know, the specimens were characterized based on the microstructure and antimicrobial properties of the film surface. The team investigated the effect of O2/Ar ratio on the structure, morphology, and antimicrobial properties of the films. They used X-ray diffraction (XRD), scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy (FTIR) to evaluate the properties of the deposited films.

The X-ray diffraction peak analysis showed (100) and (200) WO3 phases with hexagonal structure. In addition, microstrain, grain size, and dislocation density were obtained. It is noteworthy that by increasing the percentage of oxygen from 10% to 20%, the grain size was reduced from 81 nm to 23 nm, while the microstrain and dislocation density of the films was increased.

SEM results show that the WO3 films are composed of interconnected nanodots in chains, with spherical grains ranging from 10 to 100 nm in diameter. FTIR spectra showed four different bands corresponding to the O-W-O bending vibration mode and W-O-W stretching mode of the WO3 films.

The team investigated for the first time the antibacterial effect of the films on steel stainless steel substrates against E. coli, and it was observed that the number of bacteria on all WO3 samples decreased after 24 hours.

The team's work provides a strategy by which tungsten oxide films can be used for antimicrobial purposes and suggests that WO3 films are ideal for a variety of medical applications, including stainless steel medical tools, optical coatings, and antimicrobial coatings.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com