Molybdenum Wires’ Types and Applications

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 February 2022 22:44

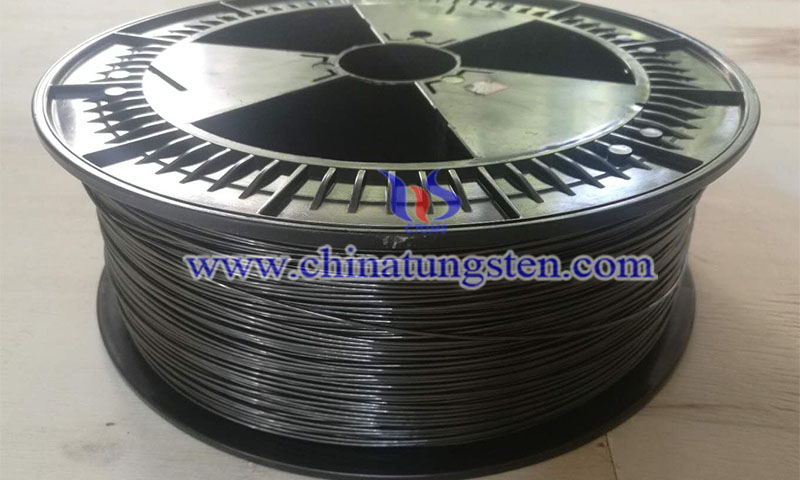

Molybdenum wires are common molybdenum product. If classified by material, molybdenum wire can be divided into pure molybdenum wire, high-temperature molybdenum wire, sprayed molybdenum wire, and wire-cut molybdenum wire and different types of molybdenum wire have different characteristics and their applications are also varied.

Molybdenum is a silvery-white metal with a high melting point that does not react with air in oxidation at room temperature. Because of its high strength, high melting point, corrosion and wear resistance, molybdenum is widely used in steel, petroleum, chemicals, electrical and electronic technology, medicine, and agriculture.

Molybdenum has a high melting point as same as tungsten but is easier to be processed. It is mainly used for high-temperature furnace parts, lighting, and electron tube. It can be made with various wire diameters and could be finished according to the application.

Pure molybdenum wires are pure and host dark gray surfaces. After alkaline washing, it becomes a white molybdenum wire. It has good electrical conductivity, so it is often used as part of a light bulb. For example, it can be used to make filament holders made of tungsten, lead wires for halogen bulbs, and electrodes for gas discharge lamps and tubes.

This type of wire is also used in aircraft windshields, where it acts as a heating element to provide defrost; it is also used in the manufacture of electronic tubes and power tube grids.

High-temperature molybdenum wire is based on pure molybdenum with the addition of lanthanide rare earth elements. This molybdenum-based alloy is preferred over pure molybdenum because it has a higher recrystallization temperature, higher strength, and better ductility after exposure to high temperatures. In addition, after being heated above its recrystallization temperature and processed, the alloy forms an interlocking grain structure that helps resist sagging and structural stability.

Therefore, it is often used for high-temperature structural materials such as printed pins, bolts and nuts, halogen lamp holders, high-temperature furnace heating elements, and lead wires for quartz and high-temperature ceramic materials.

Sprayed molybdenum wire is mainly used for automotive parts that are prone to wear, such as piston rings, gearbox synchronizing parts, gear selection forks, etc. A thin coating is formed on the wear surface, which can provide excellent lubrication performance and wear resistance to vehicles and parts subjected to high mechanical loads.

When used in wire cutting, molybdenum wires could cut virtually any conductive material, including metals such as steel, aluminum, brass, titanium, and other types of alloys and superalloys.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com