Ultrasensitive Gas Sensor Based on WO3-NiO Nanocomposites

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 01:58

Metal oxide semiconductor (MOS) materials have been widely applied for gas sensing and environmental protection, because of their wide availability and high sensitivity to low ppm concentration of gases.

Tungsten trioxide (WO3) is a n-type semiconductor material and has a good sensing response to the toxic gases It has been a widely studied material due its unique characteristics such as a wide band gap (2.6–3.2 eV) at absorption wavelength 480 nm. [26]. In comparison to other inorganic semiconductor oxides, WO3 material has its limitations, like high operating temperature (200–400 °C), low selectivity, and high power consumption. In recent times hybrid nanocomposites prepared by mixing of nano metal oxide semiconductor (n-type) materials with conducting polymers (p-type) show excellent gas sensing response at room temperature.

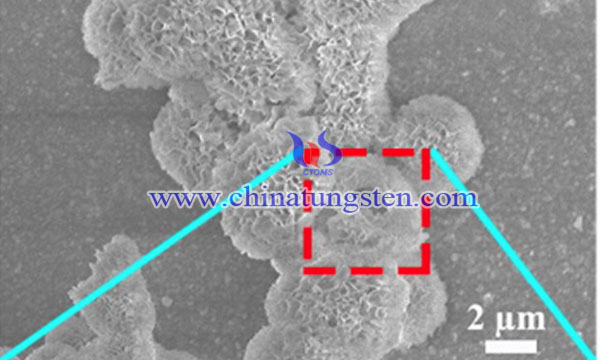

Hollow micro-/nanostructures are fascinating in many current and emerging areas of technology owing to their distinctive structural properties, having wide applications in lithium batteries, catalysis, biomedical and gas sensors. Accordingly, a simple one-pot template-free hydrothermal approach was used to synthesize hollow tungsten trioxide-nickel oxide (WO3-NiO) nanoflowers in this work. Ultrasensitive gas sensor based on WO3-NiO nanocomposites has been successfully prepared, the 10 at% WO3-NiO based gas sensor showed the best xylene sensing performance. The preparation process of is as following steps:

All involved chemical reagents were analytical grade and used directly without further purification. A template-free hydrothermal approach was employed to prepare the WO3-NiO samples with different W/Ni ratios (W/Ni = 0, 5, 10, 15, and 20 at%, respectively). In detail, 2 mmol of NiCl2·6H2O was first measured and dissolved into 30 mL of deionized water in a beaker under continuous magnetic stirring at room temperature. Then various amounts (0, 0.1, 0.2, 0.3 and 0.4 mmol, respectively) of WCl6 and 2 mmol of hexamethylenetetramine (HMT) were added into the beaker. About five minutes later, 2 mL of ethanolamine was dropped into the mixed solution. Next, the final solution was transferred into the 45 mL Teflon-lined stainless steel autoclave after magnetic stirring for 20 min at room temperature, heating at 160 °C for 12 h. When the autoclave cooled to room temperature, rinsing and centrifuging the resulting precipitate with ethanol and deionized water alternately several times, and drying the precipitate at 80 °C overnight. Finally, the pure NiO (0 at%), 5, 10, 15 and 20 at% WO3-NiO samples were prepared by annealing above precipitates at 400 °C for 2 h in air.

In summary, ultrasensitive gas sensor based on WO3-NiO nanocomposites has been successfully prepared. The 10 at% WO3-NiO based gas sensor showed the best xylene sensing performance, showing its potential applications for fast, sensitive and selective xylene detection. In detail, the 10 at% WO3-NiO based gas sensor responded and recovered fast upon exposure to 50-ppm xylene, giving a 228.8 times higher sensitivity (354.7) than that of pure NiO sensor. Furthermore, this sensor showed ultralow detection limit (1.5–50 ppb) and excellent selectivity to xylene with low cross-responses to interfering gases (e.g. Sxylene/Sethanol = 10.3).

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com