Ultrafine Pt-WO3 Nanofibers Synthesized via Ammonium Metatungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 August 2021 16:40

Photocatalytic degradation has emerged as a promising technology for complete wastewater decontamination because of its organic and synthetic dormancy, essential limit, cost-viability, and long-haul security against chemical corrosion.

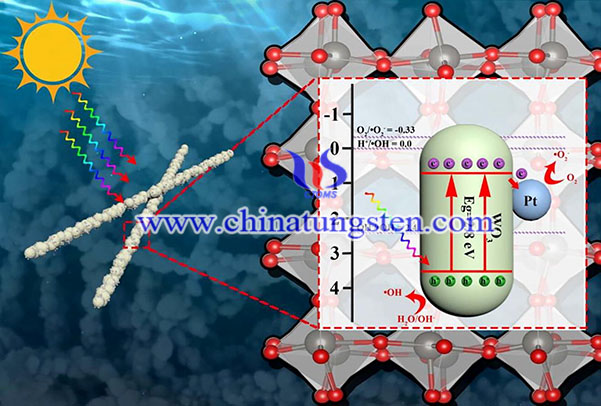

Tungsten trioxide (WO3) is an optimistic entrant for photocatalytic activity owing to its versatile properties like optical, physical, and biochemical properties, cost-effective and visible light-responsive. However, pure WO3 nanorod has a lower conduction band level (VCB) can't offer the adequate potential for reacting to electron acceptors, instigating the recombination of photogenerated charge carriers, and slow charge transfer rate limits the photocatalytic performance. Nanostructured WO3 has been examined to increase surface area and reduce grain boundaries. Moreover, researchers have developed various approaches to improve the photocatalytic performance of WO3, such as surface hybrid reduced graphene oxide (RGO) coating, semiconductor coupling, and noble metal decoration.

Thus, Pt nanoparticles (Pt NPs) loaded on the surface of ultrafine WO3 nanofibers have been prepared by a combined electrospinning and reduction strategy. Ultrafine Pt/WO3 nanofibers are fabricated from ammonium metatungstate and applied as an efficient photocatalyst with enhanced photoelectrochemical properties. The preparation procedures of ultrafine Pt-WO3 nanofibers is as below:

First, 0.985 g (0.4 mmol) ammonium metatungstate ((NH4)6H2W12O40) was dissolved into 3 mL deionized water to obtain solution A. Meanwhile, solution B was prepared by dissolving 0.8 g polyvinylpyrrolidone (PVP, K-90) into 8 mL N, N-dimethylformamide (DMF). The precursor sols were obtained by mixing solution A with B, followed by stirring for 6 h at room temperature. The precursor sols were electrospun with the parameters as follows: 2.26 mL/h push speed in 20 mL plastic syringe, 20 cm receiving distance away from aluminum foil collector, and 20 kV applied voltage. Finally, the samples were obtained by calcining the precursor nanofibers at 550 °C for 1 h with a heating rate of 1 °C/min.

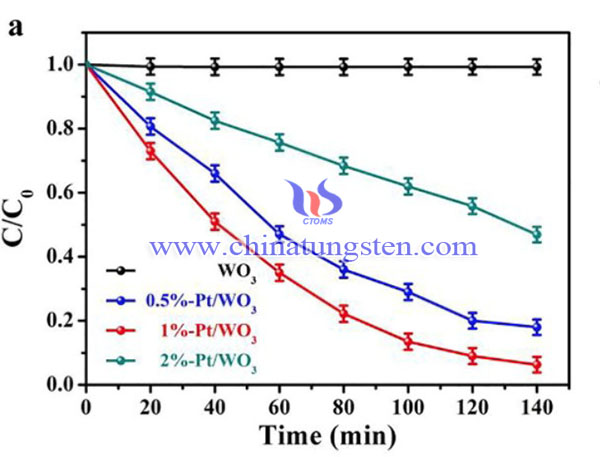

Then, 0.164 g (0.7 mmol) WO3 nanofibers and a certain amount of H2PtCl6 solution were added to 50 mL ethylene glycol (EG) and the resultant suspension was moved into 150 mL flask at 160 °C for 20 min. The obtained products were separated by centrifugation and washed several times with deionized water and ethanol, and then dried at 40 °C for 12 h. The contents of Pt NPs could be tuned by controlling the molar percentages of H2PtCl6 to WO3 in suspension. The corresponding products were labeled as 0.5%, 1% and 2%-Pt/WO3 nanofibers, respectively.

In conclusion, ultrafine Pt-WO3 nanofibers are fabricated from ammonium metatungstate and applied as an efficient photocatalyst with enhanced photoelectrochemical properties. The Pt modified ultrafine WO3 (Pt/WO3) nanofibers with average diameter of 70 nm, The ultrafine Pt/WO3 nanofibers exhibited much higher photocatalytic activity than pure WO3 nanofibers under visible-light irradiation, and the content of Pt NPs was the key factor to improve the photocatalytic performance of WO3 nanofibers, 1%-Pt/WO3 nanofibers provide the enhanced photodegradation efficiency (93.7%) under the visible-light irradiation for 140 min.

- AMT Manufacturer & Supplier, Chinatungsten Online: ammonium-metatungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com