Plasma Synthesis of Tungsten Carbide Nanopowder from Ammonium Paratungstate (APT)

- Details

- Category: Tungsten Information

- Published on Sunday, 24 May 2020 19:44

Cemented tungsten carbide (W2C) has attracted great attention due to its properties of high hardness and good wear resistance. It is mostly applied to the metallurgy, drilling, and mining industries under harsh conditions of high-pressure, high-temperature, and corrosive environment. The mechanical properties such as hardness, compressive strength, and transverse rupture resistance depend on the composition and microstructural parameters including the grain size. The reduction in scale of the microstructure also means an increase in the dislocation density and the amount of grain boundaries per unit area.

In addition, a lower consumption of temperature and time is required to get dense structure with a fine grain size. Users have claimed that the smaller grain size of tungsten carbide gives a significant improvement in the mechanical properties of the consolidated compacts. Thus, the production of nanosized tungsten carbide powder is critical.

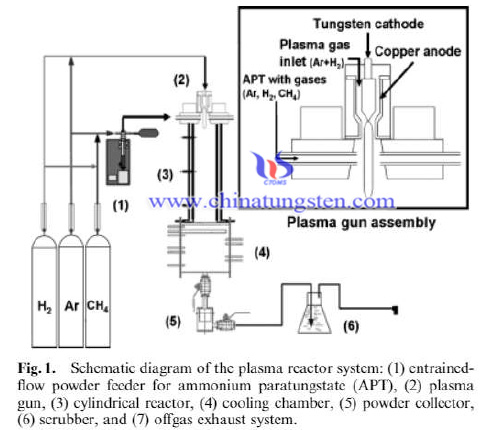

In view of this, Scientists have introduced a new plasma processing for the production of nanosized powders by vapor phase reactions. This method uses ammonium paratungstate (APT) as the precursor. The production processes are as follows:

Argon (99.9%) and hydrogen were used as the primary and the secondary plasma gas, respectively. Argon gas also passed through the powder feeder as a carrier gas and an inert gas, respectively, to keep the atmosphere in the container inert. The reactor was heated by the plasma flame generated until its temperature reached a steady level, before adding the precursor. The mixture of CH4 and H2 also flowed through the precursor feeding system to bring APT powder into the plasma flame. The final powder was collected using a Teflon-coated polyester filter with a pore size of 1 µm. The reactor was purged with an Ar flow of 5 L/min (250 °C, 86.1 kPa total pressure) for 10 min before and after each experiment.

The product was analyzed by the use of X-ray diffraction (XRD) and the morphology with particle size analysis was done by the use of TEM. The total carbon contents of the powders were measured with a Carbon Determinator). The grain size of the synthesized powders was calculated from the XRD pattern.

Argon (99.9%) and hydrogen are used as the primary and secondary plasma gases, respectively. Argon gas also passes through the powder feeder as a carrier gas and an inert gas, respectively, to keep the atmosphere in the container inert. Before delivering the precursor to the plasma flame, the reactor is heated by the generated plasma flame until its temperature reaches a stable level. The mixture of CH4 and H2 also flows through the precursor feed system, bringing the APT powder into the plasma flame. A Teflon-coated polyester filter with a pore size of 1 gm was used to collect the resulting powder. Before and after each experiment, the reactor was purged with an Ar flow of 5 Limin (250 ° C, 86.1 kPa total pressure) for 10 minutes.

The product was analyzed by using X-ray diffraction (XRD), and the morphology with particle size analysis was performed by using TEM. The total carbon content of the powder was measured with a carbon analyzer. By applying the Scherrer equation, the grain size of the synthetic powder is calculated from the XRD diagram.

The results show that the produced tungsten carbide powder has a grain size less than 20 nm. The plasma synthesis of tungsten carbide nanopowder from ammonium paratungstate is proved to be feasible. It is an efficient technique compared with other conventional processes to prepare nanosized tungsten carbide. Because of the high temperature, the nanosized powder can be yielded in a shorter time.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com