Synthesis of W-Cu Composite Powder by Sintering Ammonium Paratungstate (APT) and Copper Nitrate

- Details

- Category: Tungsten Information

- Published on Sunday, 24 May 2020 19:24

Tungsten and Copper (W-Cu) composite powder has a wide applications in electronics, electromechanical, military, and aerospace and other industries. This is due to its excellent thermal and electrical conductivity. The properties of these powders are dependent on their composition, characteristics of the starting powders and its synthesis procedures.

Scientists have invented a synthesis method of W-Cu composite powder by sintering ammonium paratungstate hydrated (APT) and hydrated copper nitrate.

Preparation of W-Cu composite powder

The W-30 wt% Cu composite powder was prepared from manual mixing of ammonium paratungstate hydrate with Copper nitrate hydrate in stoichiometrically calculated ratios of 30 wt% Cu and 70 wt% W in a mortar using a pestle. Then powders were placed in an alumina boat and reduced in a resistance furnace 800 °C. Heating rate was 10 °C/min and powder was isothermally kept at 800 °C for 30 min. The used reducing gas was hydrogen, with a flow of approximately 6 ml/sec. Gas flow was kept until the furnace cooled to 500 °C and tehn Argon flow was used to room temperature in order to avoid oxidation.

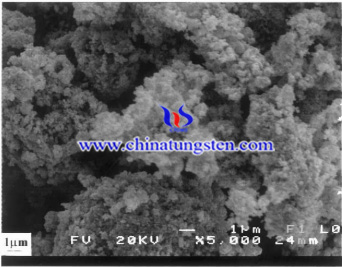

The obtained materials were characterized by XRD, SEM, EDS and particle size analysis. The density of sintered sample and the final structure were observed through density measurements according the Geometric density and by optical microscopy and scanning electron microscopy, respectively.

Powder compacting

Cylindrical samples with 5mm diameter and 3 to 4mm thickness were prepared for sintering. These samples were uniaxially compacted in a 5 mm diameter steel mold using a single section press with pressures of 500 MPa.

Sintering

The green samples were sintered in a tubular furnace under an argon atmosphere with 10 ml/sec flow at 1200 °C. Heating rate was 10 °C/min and samples were isothermally held 60 minutes. The samples were cooled in the furnace to room temperature and then the sintered bodies were characterized by OM, SEM and EDS. Density measurements and microhardness Vickers (HV) were also realized.

The obtained materials were characterized by XRD, SEM, EDS and particle size analysis. The density of sintered sample and the final structure were observed through density measurements according the Geometric density and by optical microscopy and scanning electron microscopy, respectively.

CONCLUSION

The obtaining of the W-30 wt% Cu composite powder from APT and copper nitrate favored its sintering due to good phase dispersion and the powder particle size as well as its crystallite size of 25.64 nm. The result showed that the density of produced W-30 wt% Cu may reach very close to theoretical density when sintered at 1200 °C. The microstructural analysis by SEM shows that Cu fills the voids and forms some copper rich regions. Therefore, it is possible to obtain a homogeneous structure with a density close to the theoretical density when the W-30 wt% Cu powder is obtained from APT and copper nitrate without a previous refining.

Therefore the method of obtaining the composite powder is feasible to sinter W-30 wt% Cu powder due to a greater dispersion and homogenization of phases and the average particle size.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com