Tungsten Selenide-Graphene-Carbon Nanofibre Composites

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 16:47

Carbon fiber is a new type of fiber material with more than 95% carbon content. Its quality is lighter than that of metal aluminium, but its strength is higher than that of steel, and it has the characteristics of corrosion resistance and high modulus. It is an important material in national defense, military and civil fields. At the same time, the good conductivity and thermal conductivity of carbon fibers make them have a broad application prospect in the field of energy storage and conversion in the new generation.

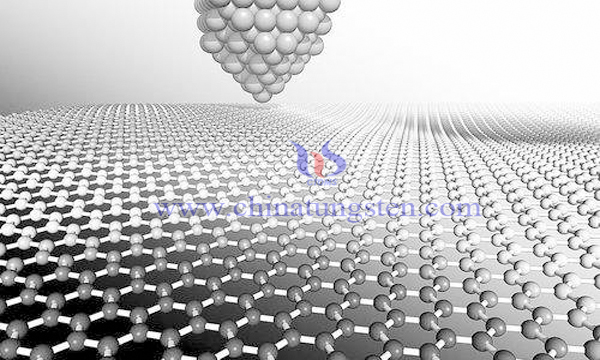

The researchers believe that graphene oxide can be compounded by its interaction with the surface of electrospun nanofibers, and eventually graphene-coated carbon nanofibers can be obtained by one step carbonization. Then tungsten selenide nanosheets with excellent electrochemical activity can be loaded on graphene-functionalized carbon nanofibers by simple solvothermal reaction, which can increase simultaneously. Strong electrical conductivity and electrochemical activity of electrospun nanofibers lead to new materials with strong functions.

The preparation process of tungsten selenide-graphene-carbon nanofibers composite is as follows:

(1)Polyacrylonitrile spinning solution was prepared under stirring and oil bath conditions.

(2)Polyacrylonitrile nanofibers were prepared by electrospinning.

(3)The surface functionalized oxidized polyacrylonitrile nanofibers were obtained by pre-oxidation of step (2) polyacrylonitrile nanofibers under programmed temperature control.

(4)Graphite oxide was dispersed in deionized water, and stable dispersion of graphene oxide was obtained by ultrasound.

(5)The oxidized polyacrylonitrile nanofibers obtained in step (3) were immersed in the graphene oxide dispersion solution obtained in step (4) and placed in a static position to make graphene oxide self-assemble on the surface of the oxidized polyacrylonitrile nanofibers; after cleaning and drying, the graphene oxide/oxidized polyacrylonitrile nanofibers were obtained.

(6)Graphene oxide/oxidized polyacrylonitrile nanofibers obtained in step (5) were carbonized at high temperature to obtain graphene/carbon nanofibers composite.

(7)Selenium powder was weighed and selenium solution was prepared. Tungsten selenide nanosheets were grown on the surface of graphene/carbon nanofibers composite prepared by solvothermal method in step 6, and tungsten selenide-graphene-carbon nanofibers composite was obtained.

The prepared tungsten selenide-graphene-carbon nanofibers composite retains good self-supporting and flexibility of electrospun non-woven fabrics, has excellent conductivity and electrochemical activity, and has broad application prospects in the field of new energy batteries.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com