Lead Tungstate Spindle Crystal Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 11:56

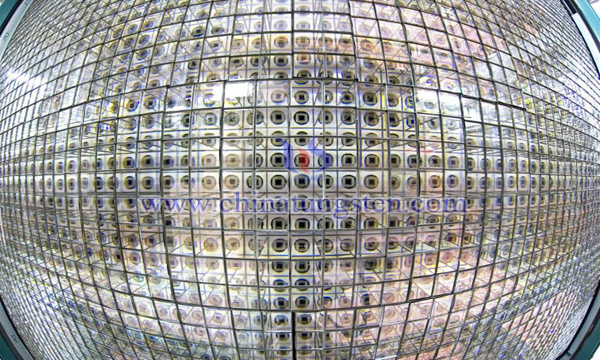

Lead tungstate is an important inorganic scintillator material. Due to its excellent scintillation performance, short attenuation time, high irradiation hardness, high density and low cost, it has been widely used in many fields such as photocatalysis, microwave, scintillator, luminescence, optical fiber, detector and so on.

In order to solve the related problems, some scholars have designed a set of preparation process of lead tungstate spindle crystals. The process is simple, the morphology is controllable and there is no environmental pollution.

Step 1: Disodium ethylenediaminetetraacetate was dissolved in deionized water to form an aqueous solution of disodium ethylenediaminetetraacetate. The concentration of ethylenediaminetetraacetate in the solution was adjusted to be 0.03~2.0 mol/L.

The second step is to dissolve lead nitrate in deionized water to form an aqueous solution of lead nitrate. The concentration of lead 2+ in the solution is adjusted to be 0.03~2.0mol/L.

Step 3. The ethylenediaminetetraacetic acid disodium aqueous solution prepared in step 1 and lead nitrate aqueous solution prepared in step 2 were mixed, and the molar ratio of ethylenediaminetetraacetic acid disodium and lead nitrate was 1:1. The lead ethylenediaminetetraacetic acid precipitation solution was obtained, and then it was placed for 0.5-1 hour.

Step 4. Dissolve sodium tungstate in deionized water to form sodium tungstate aqueous solution. Adjust the concentration of WO42- ion in the solution to 0.03~2.0mol/L.

Step 5. Sodium tungstate aqueous solution prepared by step 4 and lead ethylenediaminetetraacetate precipitation solution prepared by step 3 are mixed. The molar ratio of sodium tungstate and lead ethylenediaminetetraacetate is 1:1. Then the container containing the mixed solution is put into ultrasonic wave for ultrasonic treatment. The power of ultrasonic wave is 100-1000W, the time of ultrasonic treatment is 20-60 minutes, and then distilled water is used. Lead tungstate spindle crystals were obtained after repeated washing, filtration and drying at 50oC.

The preparation method of lead tungstate spindle crystal has the advantages of simple process, controllable morphology, simple operation, no use of any organic surfactant, low cost, etc. It can effectively control the morphology of lead tungstate nanocrystals and is easy to industrialize. The spindle crystal of lead tungstate prepared by this method has a large specific surface area due to its special morphology. Therefore, it will have a wider application prospect in the fields of optoelectronics, scintillators, solid-state luminescence, detectors and so on.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com