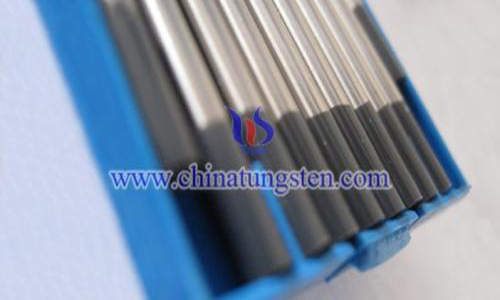

New Manufacturing Scheme of Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 April 2019 16:54

At present, tungsten-rare earth oxide electrode materials for argon arc welding, plasma cutting and steelmaking at home and abroad are manufactured by powder compaction, sintering and deformation.

Traditional methods have many processes and high energy consumption. In the process of drying and thermal decomposition of coated powder, NO2 (NO) and SO2 harmful gases are released. In order to overcome the above shortcomings, a new method of manufacturing rare earth tungsten electrode has been proposed by some scholars. This method not only has simple process, low energy consumption and low cost, but also has high surface activity, high purity and no harmful gas precipitation. The prepared electrode has excellent arc performance and long service life. Its manufacturing process includes:

(1) Ingredients

The specific gravity of ammonium tungstate solution used is 1.28 g/cm3 and the volume is 60 liters. The fineness of WCe powder is controlled at 2.00 Mu and the content of CeO2 in WCe powder is 2.3%. According to Fig. 1, the total amount of CeC2 added is 378 grams.

After mixing ammonium tungstate solution with CeO2 powder, heating and stirring for 1.5 hours at 2.0 vapor pressure. When the specific gravity is 1.06-1.08g/cm3, stopping heating, adding 30 liters of cold deionized water, stirring for 30 minutes, and depositing for 45 minutes.

(2) Evaporative crystallization

The prepared solution (ammonium tungstate solution added with rare earth oxide) was heated under pressure and stirred to evaporate. The air pressure is controlled between 1.5 and 2.5 atmospheric pressures, the heating temperature is 75-85 ℃, and the heating and stirring time is 1.5-3 hours.

(3) Prereduction

Pre-reduction is carried out in a hydrogen-protected continuous reduction furnace. The furnace temperature is controlled at 400-500 ℃, the holding time is 1-2 hours, and the pre-reduction product is W4O11 CeO2 powder.

(4) Secondary reduction

Secondary reduction is carried out in a continuous hydrogen reduction furnace. W-CeO2 powder was prepared by reducing high temperature zone at 800-950 ℃ and holding time at 3-4 hours.

(5) Compression moulding

The second reduction powder is mixed by boat mixer and sifted. After sieving, the powder is added with binder, and after mixing evenly, the required shape is pressed on the press.

(6) Pre-burning

The compacted billet is pre-fired in a molybdenum wire furnace. Pre-firing temperature is 1100-1250 ℃, holding time is 40 minutes.

(7) Vertical melting

The pre-sintered billet was vertically melted on a bell-type water-cooled hydrogen vertical melting machine. The technological parameters of vertical melting are as follows: heating up time 15-20 minutes; holding current 2650-2850 amperes, holding time 20 minutes; density D of billet after vertical melting should be greater than 17.4 g/cm3.

Compared with the current excellent wet process, the new rare earth tungsten electrode manufacturing scheme simplifies two main processes, i.e. the roasting of ammonium paratungstate and the mixing and stirring drying process of WO3 and rare earth salt solution are omitted, which obviously saves man-hour and reduces energy consumption, improves productivity and eliminates the environmental and human pollution caused by NO2 and SO2 in the roasting and reduction process of rare earth salt. The yield of harmful gases is 2-5% higher than that of the current process.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com