Ultrafine Tungsten-Copper Composite Powder Preparation by New Technology

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 15:50

Tungsten-copper composites have the advantages of tungsten and copper, high density, low coefficient of thermal expansion, good electrical and thermal conductivity, and are widely used as electrical contact materials, electrode materials and microwave power device substrates in the modern microelectronics information industry. The electronic packaging material such as the connecting member and the heat dissipating component and the heat sink material can be used as the guide material of the electromagnetic gun and the armor-piercing medicinal cover of the armor-piercing projectile.

With the continuous improvement of industrial requirements, new processes are constantly emerging. Recently, some scholars have made full use of the advantages of the existing technology, and prepared ultrafine tungsten copper composite powder by chemical sol-spray drying calcination - (low temperature + high temperature) two step hydrogen reduction process.

(1)The material consists of tungsten and copper, of which copper is 1-99wt%, and the rest is tungsten.

(2)One kind of metatungstate, paratungstate, tungstic acid and one kind of copper nitrate, copper chloride and copper sulfate crystals are used as raw materials.

(3)The raw materials in (2) are mixed in proportion to the required tungsten and copper components to prepare a solution with a concentration of 10-35 wt%.

(4)A small amount of acid or alkali was added to the solution to adjust the pH from 3 to 4.

(5)Polyethylene glycol (PEG), stearic acid (or stearate), N, N-dimethylformamide were added into (4) solution, and the colloids were obtained by stirring well.

(6)the colloid in (5) was sprayed and pyrolyzed on the spray dryer to prepare the ultrafine mixed powder precursor.

(7)Tungsten-copper oxide composite powders were obtained by calcining the precursors of (6) ultrafine mixed powders for 0.5-3 h at 150-500 ℃.

(8)Ultrafine tungsten-copper composite powder were prepared by reducing (7) precursors of ultrafine powders in H2 atmosphere at 120-400 ℃ and 500-900 ℃ for 30-150 min, respectively.

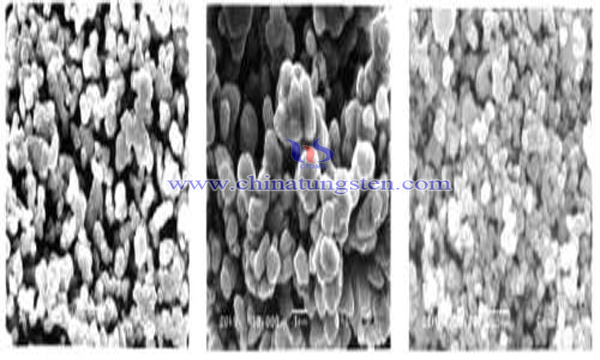

The prepared ultra-fine W-Cu composite powders are spherical particles, which have good fluidity and formability. They can form complex parts under 100-500 MPa pressure, and can solve the problem that the melt infiltration method is difficult to deform.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com