Thin Plate Tungsten-Titanium Alloy Film Lithography Process

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 15:32

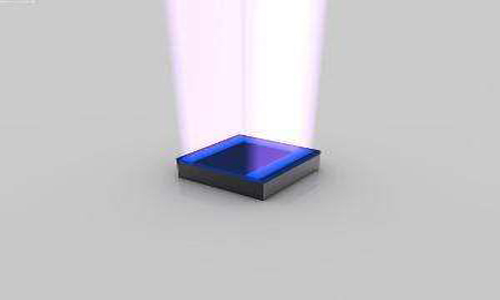

Tungsten-titanium alloy (WTi) is widely used in micromechanical manufacturing. The tungsten-titanium alloy thin films deposited by sputtering process have high density, moderate film stress, excellent surface smoothness, excellent thermal and chemical stability, so they are ideal materials for structural layer and sacrificial layer in the manufacturing of MEMS.

Tungsten-titanium alloys have unique advantages. On the one hand, tungsten-titanium alloys can be rapidly and stably etched by hydrogen peroxide (H22) at 40 ℃ without destroying most common metal layers such as aluminum and copper. Most acids do not etch tungsten-titanium alloys, which makes tungsten-titanium alloys have good etching selectivity with other metals.

A simplified lithography process for tungsten-titanium alloy has been proposed by some scholars. The specific steps of the process are as follows:

Step 1: All process steps are implemented in the clean room. Substrate substrates covered with tungsten-titanium alloy films, including but not limited to silicon wafers (hereinafter referred to as substrates), are cleaned and dried with acetone, isopropanol and deionized water.

Step 2: The liquid positive photoresist is rotated onto the substrate to be etched by using a leveler. The thickness of photoresist can be controlled by adjusting the speed of the leveler. The glued substrate is heated on the hot plate to solidify the adhesive layer. When the glue is fully cooled, ultraviolet exposure is carried out by using a mask on the alignment exposure machine. The exposed substrate is then fully developed in the developing solution. The developed substrate is heated on the hot plate to completely solidify the adhesive layer. The leveling and exposure process is completed in the yellow light region.

Step 3: Cool the substrate of the heat-curable adhesive layer in the fume hood with air circulation filter equipment to ensure that the solvent in the adhesive layer evaporates sufficiently. The cooling process is completed in the yellow light region.

Step 4: Through temperature control, the 30% hydrogen peroxide etching solution temperature is maintained at 20 ℃, and the cooled substrate is put into the etching solution to begin etching. The etching effect of hydrogen peroxide on the photoresist film is greatly slowed down at 20 ℃. According to the experiment, the etching time of the film is much longer than that of the tungsten-titanium alloy film. Therefore, this reaction can achieve high-precision etching of tungsten-titanium alloy film without destroying the photoresist excipient layer, but only one step photolithography is needed.

Step 5: Use acetone and isopropanol to wash off the photoresist and finish the process.

This simplified lithography process can achieve high-precision lithography of tungsten-titanium alloy film structure. After lithography, the surface of tungsten-titanium alloy structure is flat, the outline is clear, and the lithography quality is very high.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com