Preparation of Ultrafine Tungsten Carbide: Coprecipitation

- Details

- Category: Tungsten Information

- Published on Sunday, 14 January 2018 13:41

Ultrafine tungsten carbide has excellent hardness and bending strength, which is a new direction for the development of tungsten carbide at present. The preparation methods of ultrafine tungsten carbide are mainly divided into three categories. (1) Superfine tungsten powder is first made, and then superfine WC powder was obtained by carbonization. (2) Direct carbonization of tungsten compounds. (3) Coprecipitation (WC-Co compound precipitation).

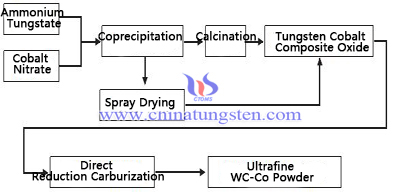

The precipitation method has the advantages of small particle size and high reaction, and it also has some disadvantages, such as the difficulty of mass production. As for WC-Co precipitation method, it is a co-precipitation of tungsten salt and cobalt salt in liquid phase. The precipitate was then completely decomposed at low temperature to prepare the precursor of tungsten cobalt compound with high dispersibility and high activity. Then the reduction was carbonized into a superfine WC-Co composite powder in a fixed bed or a fluidized bed.

Technological Path

The precipitation method needs to be used together with the spray drying process. Typical coprecipitation process path: first, the ammonium tungstate solution is put into the reactor to stir. Slowly adding cobalt nitrate to form purple precipitation. Tungsten cobalt salt is obtained after a few hours’ static stirring, filtering and washing. Superfine grain WC-Co powder is prepared by continuous direct carbonization at carbonization temperature.

Process Characteristics

The equipment used in chemical precipitation method is simple. Its process can be easily controlled, and the prepared powder has the advantages of high particle size distribution and uniform reactivity. However, in the process of preparation, there is difficulty in mass production of precipitates as the it is easily introduced from impurities and easy to be colloid and difficult to filter and wash.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com