Preparation of Superfine Crystal Tungsten Carbide: Mechanical Alloying

- Details

- Category: Tungsten Information

- Published on Sunday, 14 January 2018 13:43

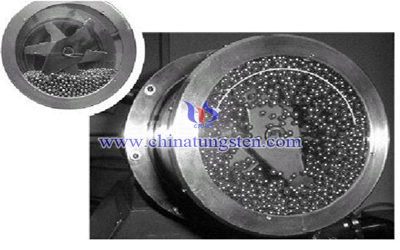

Superfine crystal tungsten carbide has become a new direction for the development of tungsten carbide. It can be obtained in a variety of ways, including mechanical alloying. Mechanical alloying (MA) refers to the metal or alloy powder by powder particles and the ball long time intense impact and collision in high-energy ball mill, the powder particles produced repeated cold welding, fracture, leading to atomic diffusion in powder particles, so as to obtain a powder preparation technology of alloying powder.

In the process of ball milling, the harder the powder is, the harder the recovery process is, and the smaller the grain size can be achieved. Moreover, due to the high hardness of the material, the dislocation slip is difficult to carry out, and the dislocation density in the lattice will be very large. These provide a fast diffusion channel for the alloying, which accelerates the alloying process.

Research shows that when using WC powder and cobalt powder with particle size of 1μm, high energy mechanical attrition can reduce the grain size of WC in WC-Co composite powder significantly. After 36h grinding, WC-Co powder with average grain size less than 0.5μm can be prepared.

In this method, the particle size of WC-Co composite powder is related to the grinding time. Generally, the longer the grinding time is, the smaller the particle size is. Therefore, WC-Co composite powder can be obtained directly without external heating. However, disadvantages are that some impurities are easy to be introduced in the long milling process, the surface area of the powder is small, the size of particle size is large, and the grain size distribution is uneven.

Methods which coordinate mechanical alloying and reduction carbonization can improve the shortage of simple mechanical alloying method. Specific methods are as follows: first, WC and Co powder will be reduced to carbonization at H2 and Ar gas at 400-700℃ temperature. Then after high energy ball milling for a period of time, the ultrafine WC-Co powder of which the particle diameter is from 0.2μm to 0.3μm can be obtained. However, with complex process steps, this method is not suitable for rapid reaction.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com