Nano Tungsten Carbide / Carbon Composites and Their Preparation Methods

- Details

- Category: Tungsten Information

- Published on Saturday, 06 January 2018 23:34

Nanocrystalline tungsten carbide has a catalytic activity similar to platinum, which is stable in physical and chemical properties and low in price. With the emphasis on clean energy, tungsten carbide has attracted widespread attention in the field of catalysis, such as direct methanol fuel cell, catalytic hydrogen evolution, super capacitor and catalytic desulfurization. In the field of electrochemistry, tungsten carbide as an anode catalyst has the advantage of not only having catalytic properties, but also difficult to be poisoned by carbon monoxide, such as platinum and palladium. Therefore, nano tungsten carbide as a catalyst can partly replace or to a certain extent save precious metals such as platinum, palladium and so on, and its application prospect is broad.

Preparation method of tungsten carbide as the traditional solid-state reaction method, by tungsten powder and carbon powder at 1600 ℃ high temperature reaction, tungsten carbide particles prepared by this method easy agglomeration and small specific surface area, but can only meet the needs of metallurgical industry, can not effectively play its catalytic role. In electrochemical applications, porous carbon supports play an important role in improving the catalytic activity and stability of tungsten carbide, which is mainly due to the good conductivity of carbon carriers. The high specific surface area of carbon supports is conducive to the high dispersion of tungsten carbide. The open channel structure of carbon carrier is helpful to the "mass transfer" process of the catalytic reaction; the chemical and physical stability of the carbon carrier is good, and it is suitable for various application environments.

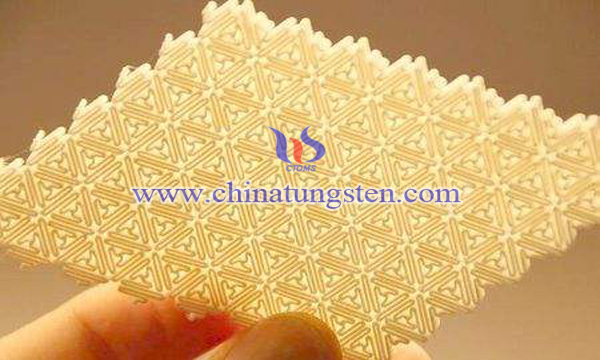

The tracheid structure of wood with unidirectional arrangement (pore structure), the fibrous tissue from nanometer to micrometer cell wall and membrane structure of the tracheid organization, to millimeter rings, forming a unique multi-level, tracheid structure, fibrous and anisotropic biological structure; The main components of wood are lignin, cellulose and hemicellulose, and the carbon in the main components is about 44%. Therefore, wood can not only be used as a structural template for biosynthesis, but also can be used as a carbon source and a structural template for the preparation of carbide composite materials.

The main steps of making porous nano tungsten carbide / carbon composites by wood as structural formwork are as follows:

(1) Preparation of precursor solution: 40 ℃, the amount of template is dissolved in a certain amount of ethanol and water mixed solution, and then followed by adding carbon source and tungsten source, stir to obtain a uniform transparent solution, the precursor solution;

(2) Vacuum impregnation: The precursor solution is transferred to a certain amount of wood flour, vacuum-impregnated for 30 to 90 minutes, then volatilized at 30 to 60 ℃ to remove the mixed solvent, dried, and then cured at 100 to 150 ℃ 12 to 48 hours to obtain the prepolymerization product;

(3) Carbonization and reduction: in the reducing atmosphere, the prepolymerization product is placed in a high temperature reaction furnace and roasted for 1~7 hours at 700~1400 degrees centigrade, then cooled and lapping, then the porous tungsten carbide / carbon composite material can be obtained.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com