Cemented Carbide Porous Material Manufactured by Powder Sintering

- Details

- Category: Tungsten Information

- Published on Sunday, 07 January 2018 00:04

Because of its excellent physical and mechanical properties, porous materials have great potential in many industrial fields, such as aerospace, chemical industry, medicine, energy and metallurgy. Porous materials including ordinary iron-based, copper, bronze, nickel base, titanium and stainless steel base, these materials are the biggest drawback is the corrosion resistance is relatively poor, and high temperature, and the system needs adding pore forming agent in the preparation process, it is difficult to control the quantity and size of pores.

Hard alloy as a metal material with special properties of corrosion resistance and high temperature resistance, is widely used as a cutting tool, has been widely used in mining, oil drilling, machinery manufacturing and other fields. Carbide porous materials with high temperature resistance, wear resistance, corrosion resistance advantages, but at the same time, the porous cemented carbide process is more complex, need to add pore-forming agent, pore uneven, uncontrollable pores, pore wall is not smooth, and the raw materials used for the WC powder and cobalt powder, the production cost is significantly higher.

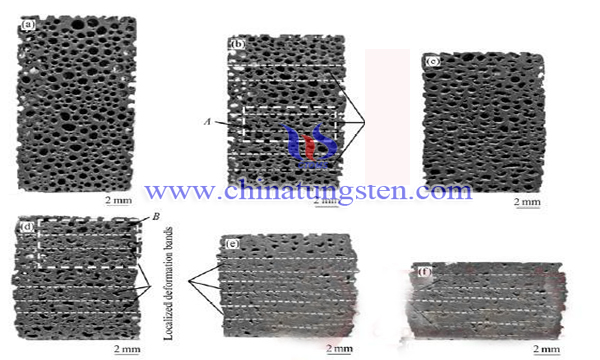

In order to reduce the cost, some scholars have proposed a solution for the powder synthesis of tungsten carbide / cobalt series porous materials. The general process as follows: first, according to a certain proportion of weighing raw material powder, the material mixed evenly, then dry powder, dried powder obtained by hydrogen reduction of tungsten carbide / cobalt composite powder, composite powder and composite powder granulation, granulation after pressed into green with a certain shape through molding process, after degreasing the green body into a high temperature and low pressure sintering furnace for sintering, with the furnace after cooling to obtain the desired tungsten carbide / cobalt porous material.

Using the tungsten carbide / cobalt solution porous material preparation method, compared with the existing technology, can not change the traditional powder metallurgy sintering equipment based on porous materials, using tungsten oxide, cobalt oxide powder and carbon powder as raw material, not adding pore forming agent, a tungsten carbide / cobalt powder metallurgy porous material is prepared by directly mixing raw materials, hydrogen reduction, billet degreasing, sintering at high temperature and low pressure. The porosity of the prepared porous material is more than 40%. The tungsten carbide / cobalt porous material prepared by this process can be used to manufacture the original parts such as filtration, separation, diversion, and current limiting. It has the characteristics of corrosion resistance and high temperature resistance.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com