Catalytic Debinding in Injection Molding: Characteristic

- Details

- Category: Tungsten Information

- Published on Sunday, 22 October 2017 00:40

From the degreasing principle, it can be seen that the catalytic debinding in injection molding has excellent degreasing properties which are different from the traditional degreasing methods (thermal degreasing and solvent degreasing).

Characteristics:

1, Fast degreasing rate. Under the action of acid catalyst, the poly (aldehyde resin) can be decomposed into formaldehyde gas quickly. The binder gas interface is pushed inward at a linear speed of 1~2mm/h. Rate of catalytic debinding in injection molding can reach 2 ~ 4mm/h, while the debinding rate of injection molding blank based on general binder is 0.2mm/h.

The Catalytic Debinding rate of injection molding is 10~20 times higher than that of traditional degreasing process. Because of the rapid debinding rate and short debinding time, the hardness and thickness of injection molded blank are small, and the maximum degreasing thickness is more than 1 inches.

2, Low degreasing temperature. Reaction temperature range is 100 ~ 140, which is lower than the melting point of POM resin (160 ~ 180), which avoids liquid phase formation. It avoids the thermal debinding process in a "green bodies" softening, or due to gravity, internal stress or viscous flow impact deformation and defects.

3, Less degreasing defects. In the gas - adhesive interface, catalytic reaction by external green gradually to the internal development, known as the "shrinking core" mechanism. Formaldehyde gas is confined to "in the porous shell region, can easily through the green is the external porous region quickly escape. As no stress inside, there will not produce green bubbling and cracking of debinding defects.

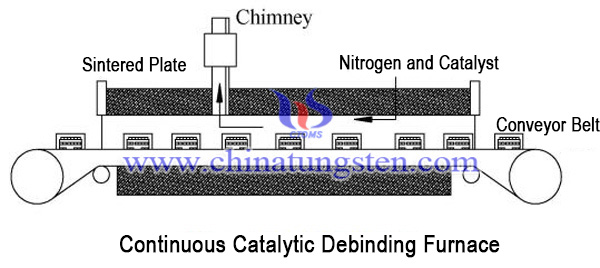

4, Continuous debinding and sintering. Because of the rapid debinding rate and the short time required to remove the binder, the continuous debinding and sintering in the injection molding process become possible.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com