Gold-plated Tungsten

- Details

- Category: Tungsten Information

- Published on Friday, 23 May 2014 10:00

In theory, as density is 19.1g/cm3, which is approximately 70% denser than lead, uranium could be used as material of making fake coin.

However, tungsten alloy jewelry is weakly radioactive and not as dense as gold, but usually works as gold substitution, so it does not appear to be a practical method.

Then people have discovered that tungsten is environmental-friendly, durable and hardness, the most important is that its density of 19.25g/cm3 is just about the same density as gold (19.3g/cm3), which bears the similar specific gravity. These advantages make tungsten alloy jewelry enjoys the superiority to be the best substitute for the costly metal oftungsten alloy jewelry gold or platinum.

It is necessary to tell that tungsten gold-plated would not work for several reasons but a coin with a tungsten center and gold all around tungsten alloy jewelry could not be detected as counterfeit by density measurement alone.

Tungstenufn Maacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Application of Rivet

- Details

- Category: Tungsten Information

- Published on Thursday, 22 May 2014 14:58

Before welding techniques and bolted joints were developed, metal framed buildings and structures such as the Eiffel Tower, Shukhov Tower and the Sydney Harbor Bridge were generally held together by riveting. Also automobile chassis were riveted. Riveting is still widely used in applications where light weight and high strength are critical, such as in an aircraft. Many sheet-metal alloys are preferably not welded as deformation and modification of material properties can occur. Common but more exotic uses of rivets are to reinforce jeans and to produce the distinctive sound of a sizzle cymbal.

When the rivet is cherry red, place the cavity of the air tool over the end of the rivet and turn on the tool. This works great and is much quicker than a bucking bar. If necessary you can heat and re do with the air tool. The finished job should look like the factory rivets or better and should be stronger than if the assembly were bolted together. This is not the easiest project in restoring an automobile but can be mastered with patience and common sense.

Tungstenufn Maacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Heavy Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 May 2014 16:06

Tungsten is a rare metal, is also an important strategic material, and in ancient times was known as the "tungsten heavy alloy". 1783 Spanish named Deep Air Asia. The tungsten content in the earth's crust is 0.001%. There are about 20 minerals containing tungsten found until now. Tungsten deposits in general along with the activity and the formation of granitic magma. After smelting tungsten is silver-white lustrous and hard metal with high melting point.

Tungsten, also known as Wolfram, lapis ponderosas or heavy stone, has highest melting point of all elements except carbon - sources in scientific literature vary between 3387°C and 3422°C. Tungsten heavy alloy also has also excellent high temperature mechanical properties and the lowest expansion coefficient of all metals. A temperature of about 5700°C is needed to bring tungsten to boil which corresponds approximately to the temperature of the sun's surface. With a density of 19.25 g/cm3, tungsten is also among the heaviest metals. Its electrical conductivity at 0°C is about 28% of that of silver which itself has the highest conductivity of all metals.

The metal is known as tungsten in some countries and as wolfram in others, including Sweden, the country of origin of the name tungsten. The chemical symbol W, which is universally used to denote tungsten, suggests that wolfram was formerly the more generally accepted name for the element. In Britain, the mineral wolframite is also known as wolfram.

Since 1912, Tungsten heavy alloy (the element or, perhaps, an uncle) has been widely used to make the most essential part of any light bulb–the filament. Bumpers have tungsten heavy alloy with tungsten content of 3000 to 6000 one hundred watt light bulbs, depending on model and configuration.

During World War II, tungsten played a significant role in background political dealings. Portugal, as the main European source of the element, was put under pressure from both sides, because of its deposits of wolframite ore at Panasqueira. Tungsten's resistance to high temperatures and its strengthening of alloys made it an important raw material for the arms industry.

Tungstenufn Maacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advantages of Tungsten Alloy Fishing Sinkers

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 May 2014 14:58

1. Small volume

High density make tungsten alloy fishing sinkers/weights smaller than the conventional lead fishing weights. It will be hung up far less with a tungsten sinker than with a lead sinker because of its smaller size.

2. Hard

It's harder than lead fishing weight. It will not be stuck in the jowl of the fish. So the shape will be maintained longer.

3. Strong wind resistance

As the high density of tungsten, the tungsten alloy fishing sinker makes your fishing easier. It is extremely sensitive and can actually help you “feel” what the bottom is made of and what your bait is bumping into, such as brush, rocks, mud, etc.

Tungsten fishing weights/eyes are an ideal, environment-friendly alternative to lead weights, which are toxic and increasingly being labeled an environmental hazard.

Tungstenufn Maacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Fishing Sinkers 2

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 May 2014 13:57

A fishing sinker or plummet is a weight used to force a lure or bait to increase its rate of sink, anchoring ability, and/or casting distance. Tungsten alloy fishing sinker may be as small as 1/32 of an ounce for applications in shallow water, even smaller for fly fishing applications, or as large as several pounds or considerably more for deep sea fishing. Fishing sinker are formed into nearly innumerable shapes for diverse fishing applications. Environmental concerns surround the usage of most fishing sinker materials.

A fishing jig is a type of fishing lure that usually consisting of a lead sinker with a hook molded into it and usually covered by a soft body to attract fish. However, recently, tungsten fishing jig is becoming more and more popular among angles because it has the features of high density, small volume, and environmental friendly, and has been taking place of the lead sinker. Fishing Jig are intended to create a jerky, vertical motion, as opposed to spinnerbaits which move through the water horizontally. Fishing jig is very versatile and can be used in both salt water as well as fresh water. Many species are attracted to the lure which has made it popular amongst anglers for years.

Tungstenufn Maacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Bucking Bars

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 May 2014 11:48

Bucking bar is a work tool received behind work surfaces to provide a backing member in applying impact fasteners and including intermitted toolhead and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear.

Bucking bars are used on the backside of a metal rivet to counter the force of the hammering on the other side. They also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Bucking bars used to form bucktails on rivets. And come in many different shapes and sizes. They are normally made from an alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet to be driven.

The size and weight of the bar depend on the size and alloy of the rivet to be driven. Under certain circumstances, and for specific rivet installations, specially designed bucking bars are manufactured locally.

Bucking bars are normally made from tungsten heavy alloy. All edges are deburred and working surfaces are polished for troubles-free use. This helps to prevent marring of formed bucktails. Please notice that never hold a bucking bar in a vise unless the vise jaws are equipped with protective covers to prevent marring of the bucking bar.

Tungstenufn Maacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The high proportion of military defense for tungsten alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 May 2014 15:57

High density tungsten alloy is more and more used in the military defense parts production, such as bullets, armor and artillery shells, bombs, grenades, titles,shotgun bullets, bullet proof car, tank armor, guns, guns and national defense etc..The main purpose of tungsten alloy penetrators in kinetic energy is, depleted uranium(DU) calculation in direct competition.

A significant mass of tungsten has been used for the production of military trainingfacilities, as an alternative to the use of lead shot 5.56 mm ammunition. Tungstenquality, for a fixed target / fixed firing position has produced the desired soil containingtungsten concentration%, in addition to the traditional lead.

Properties of tungsten alloy

Two times the density of tungsten alloy having a melting point and steel high, heavier than lead more than 50%. High density tungsten alloy than lead with greater radiation shielding and non-toxic. Tungsten alloy contribute to electrical and thermal conductivity, and good corrosion resistance. Their low expansion coefficient, highelastic modulus. Because of these unique properties of tungsten alloys are widelyused in military, balance weight, alloy rocket assembly and bullets and other heavy metals, especially the weight of aircraft and offset the gyrocompass.

Heavy metal insert is used as the core military pellet quality is high, so the tungsten alloy are widely used in military defense.

Military tungsten alloy

Powder metallurgy (P / M) military, extended from the traditional media and sintering liquid phase sintered tungsten alloy (WHA) by powder injection molding (PIM>). The navy has hired them to the third phalanx close in weapon system (CIWS) the great advantage of the world health assembly. The army intends to research will lead totungsten alloy or composite materials, as a long rod penetrator, will perform as well as, or better than, the depleted uranium (DU) penetrator. Tungsten alloy WHAs) is the best choice, is the ideal material for national defence industry, it combines the highdensity, mechanical strength, good and easy processing performance, tungsten alloy is an important material in military defense.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military tungsten alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 May 2014 15:54

Now, the tungsten alloy is gradually being used for military products, including bullets,armor and artillery shells, grenades, rifles, bullet head, bullets, bullet proof car, tanks,artillery, raw material like creating components in. The main purpose of tungsten alloyis in the kinetic energy penetrators, they will in the depleted uranium (DU) computing instant competition.

Tungsten is a naturally occurring metal. Tungsten can be used in pure form or othermetal and alloy. Tungsten alloy is often strong, flexible, abrasion resistance. Tungsten and its alloy are used for a variety of commercial products, including the bulb's filament, X ray tube, welding, grinding wheel, ceramic pigment and flame retardant.

Many countries have been used for many years, because of tungsten and tungsten alloy ammunition to its high density and the resulting penetrator penetrating. If there is a tungsten alloy

Gold in the army's "green bullets"? "Green bullets" refers to the ammunition lead-free,to provide environmental protection by the army to provide ammunition for customers.Do not use "green" or lead-free bullets military tungsten alloy. "Green bullets" usually contains mixed together, both nylon or tin and tungsten. On the other hand, tungstenalloy, containing other metals, such as nickel, cobalt, iron or copper, which is heated to high temperature materials allowed together. Although the "green" the bullet had been in training

Army facilities operation uses a limited number, it has not been used on the battlefield.

Since its launch, more than 900000 of the "green" training ammunition has been usedin American. It relies on tungsten and nylon, mixture of tungsten and tin. This makesthe bullet has density and emission performance of the same in the case of withoutlead. Tungsten is non-toxic products, high density tungsten alloy is mainly used formetal, composite materials in military field.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Why the forging process

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 May 2014 15:49

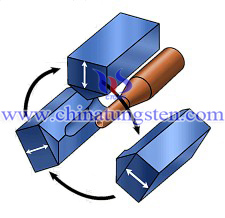

Method of forming forging is regular or irregular use of two or more than two moldaround the workpiece completely or partially reduce the cross-sectional area of a circular predetermined diameter rods or wire.

The forging process is the use of rotary forging machine forging and rolling metal so that the forming, combined machining technology, the plasticity of tungsten alloy rods,in the forging temperature range from 1200 ℃ to 1500 ℃ from. Metal forming process,first by the local deformation gradually expanded to the whole deformation process.

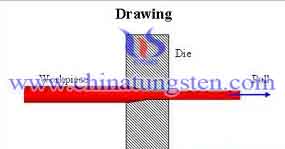

Drawing tools, but also can improve the tensile strength of tungsten alloy rod, tensile strength and prolong the service life of the tungsten alloy rod, increase the value to a large extent.

However, the drawing tools can cause serious problems, more importantly, strength and tensile strength is far better than forging low. After forging, greatly improve the tungsten alloy rod off the power and the tensile strength, improve product performance and prolong the service life and better surface quality of tungsten alloyrod. Forging technology has been widely in the foreign press die instead of drawingtools.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The process of tungsten alloy swaged rods

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 May 2014 17:40

First of all, the remaining dry tungsten powder and other elements.

And then put them into a specially designed bar, it is applied to hydraulic die more than 100000 pounds of mould.

In addition, carefully transferred to a temporary support, including tungsten,molybdenum and other elements, provided the tungsten alloy rod heatingapproximately every 45 minutes at 1600 ° C. In the electric heating tube furnacetungsten alloy rod through the protection of continuous transmission, the hydrogen oxidation at this temperature.

Then the heating section pressure tungsten alloy rod. Forging machine, this is a very good control of high speed hammer to reduce tungsten alloy rod diameter machine.Tungsten alloy rod is heated to about 1600 degrees, hydrogen oxidation. Then,quickly through forging machine makes the tungsten alloy rod diameter reduction of 10%. Then again through forging die is heated in a furnace, which will make thediameter decreased again 10%.

Finally, the processing of tungsten alloy rod. Tungsten alloy is very hard, it cannot bethe edge tool of sharp, but it can be through high-temperature hammering or cold millto produce various shapes.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com