Application of tungsten alloy swaged rods

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 May 2014 17:36

The cannon is particularly important application properties of tensile strength andtoughness. Beat the tensile strength of multiple spatial armor kinetic energypenetrators. High tensile strength, deeper under the same conditions penetrate armored rod. In addition to enough power penetrating rod must maintain sufficienttoughness, bending when hit armor without fracture, the bear cold work greaterdeformation, further improve the tensile strength and ductility of a material.

Tungsten alloy is a kind of particle composite material, including the ratio of nearlyspherical tungsten particles embedded in the matrix of very large ductile iron.Moderate to high strength of this composite material structure on the mechanical properties of high density materials in ductility and thermal conductivity, excellent.

Tungsten alloy rotary forging made of tungsten alloy rod, the performance also has atungsten alloy. Tungsten alloy rod through rotary swaging forging machine to improve the tensile properties of it. The above performance swaging tungsten alloy rodsmakes the forging rod used in many military and civilian, such as depleted uraniumpenetrators, bullets, projectile, rifle bullets and rifle projectile etc.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military high density tungsten alloy rod

- Details

- Category: Tungsten Information

- Published on Monday, 12 May 2014 15:56

High density tungsten alloy is more and more used in the military defense parts production, such as bullets, armor and artillery shells, bombs, grenades, titles, shotgun bullets, bullet proof car, tank armor, guns, guns and national defense etc.. The main purpose of tungsten alloy penetrators in kinetic energy is, depleted uranium (DU) calculation in direct competition. Recent surveys show at the Army Research Laboratory, the excellent performance of uranium from its capability, localization in ballistic missile penetration event.

What is the tungsten alloy rod?

Tungsten alloy rod sintering billet, which is composed of rod withheld or scroll work and according to production. The smaller size of the subsequent drawing production. Tungsten rod production in random length and imperial smooth surface, diameter 3mm and 3mm successfully completed. The center of the rod can also provide, can provide specific length and special fabricated according to the requirements of.

We can provide for military use high density tungsten alloy rod, such as sub bomb, wear Jia Zi bombs, the majority of customers design we are very pleased to have the opportunity and the individual specifications of. Our mission is to meet individual customer requirements. Flexibility is our strength. We are very proud to be able to find the solutions to customer problems. Because of its excellent hardness and resistance to elevated temperatures, tungsten gradually applied to today's military defense.

Normal tungsten alloy swaged forging rod, ultimate tensile strength will increase greatly. The ultimate tensile strength of tungsten alloy rod for 1050MPa general. However, rotary forging tensile strength can reach 1200MPa/min, we can even control in 1400MPa. Tungsten alloy rod is one of our main products. Tungsten alloy rotary forging bar can be used in military defense, such as depleted uranium penetrators, bullets, projectile, rifle bullets and rifle projectile etc.

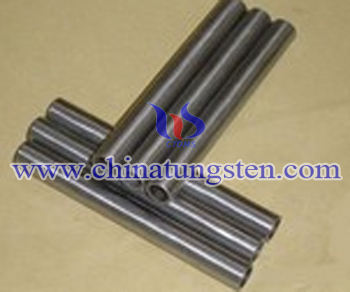

The tungsten alloy rod

Application of tungsten alloy rod

These rods can be further processed, usually used for weight, radiation shield, military defense equipment, welding and tungsten alloy extrusion die, also used in some sports, such as darts, billet and golf club etc.. Because of its high density, high melting point, low capacity, excellent hardness, excellent wear resistance and tensile strength of tungsten alloy rod of higher performance, more and more popular. Tungsten alloy pipe is mainly used in military, aerospace, machinery manufacturing, medical shield, oil drilling and movement balance etc..

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy shot ball

- Details

- Category: Tungsten Information

- Published on Friday, 09 May 2014 16:16

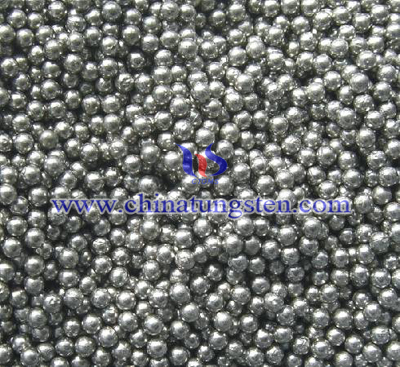

What is the tungsten alloy shot the ball?

Tungsten alloy is mainly used for hunting rifle bullet ball shotgun cartridge ball. The shotgun is a shoulder fired the gun. The bullet dispersion from the barrel injection will into a ball. Powder power role in every balls, each ball with very low energy. Hunting hunting rifle bullet ball, tungsten alloy is mainly used for small animal hunting.

Tungsten alloy shot ball

Why use tungsten alloy shot the ball?

The tungsten alloy with high density, high hardness, high temperature resistant properties of tungsten alloy as raw materials, the most popular shotgun bullet. Tungsten alloy density is about 18g/cm3, only the gold, platinum and other rare metals have similar density. The density of tungsten alloy are higher than the other bullet materials, including lead, steel and bismuth.

Conditions can produce different specifications of tungsten alloy shell ball

Tungsten alloy shell ball -1 tungsten alloy shell ball -2

Tungsten online can produce two different surfaces of tungsten alloy shell ball, a polished surface, the other is sintering.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military defense tungsten alloy cube

- Details

- Category: Tungsten Information

- Published on Friday, 09 May 2014 16:10

Tungsten alloy cube was gradually adopted at home of military products, including bullets, shells, bombs, armored, titles, shotguns, grenade bullets, bullet proof car, tank, artillery and firearms and other components. Before now, tungsten alloy products non-toxic alternative to the environmentally harmful products, such as depleted uranium bullets and shoot. Extensive application of high density metals including tungsten alloy, its intention is to create and control the action function, increase the density and non-toxic weapon. The different part of tungsten alloy, it may present a counterweight material the most perfect, tungsten alloy cube through the military defense and gradually replace today's main force in home appliances. It is widely used in tungsten alloy bullets, bombs, missiles, aircraft head balance ball, armor piercing core bullet weight, kinetic energy penetrators, armor, artillery shells, grenades and rocket components.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy green bullets

- Details

- Category: Tungsten Information

- Published on Friday, 09 May 2014 16:05

Compared with the low toxicity of lead, tungsten, will not cause pollution to the environment. Accuracy, tungsten projectiles with destruction and penetration can be comparable with lead shot. The hardness of tungsten is too large, to join the tin or nylon to processing shape. The tungsten alloy green bullets refers only to the less environmental pollution, its lethality than lead bullets go beyond. Tungsten alloy green bullets can avoid environment pollution of lead bullets. USA had planned to replace lead bullets with tungsten core bullet, but because of the cost, the termination of the R & D of tungsten alloy green bullet.

In addition, non-toxic, high density tungsten alloy, especially suitable for rifle and shotgun bullet. The toxicity of tungsten alloy, won't cause harm to human health, particularly suitable for making into tungsten alloy for daily use green bullet gun. At present, the shotgun bore of No. 10, No. 12, No. 16, No. 20, No. 28.

With the shotgun is different, shotguns are used by the police and army, killing shotgun pursuit. Tungsten alloys with high density, can improve the accuracy, comparable to lead to destruction and penetrating, is suitable for the production of tungsten alloy green bullets shotgun. For example, HK company developed CAWS automatic shotgun and Chinese self-developed QBS09 shotguns are using tungsten alloy bullet. Unlike the gun caliber is, most military shotgun with No. 12 caliber.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy armor piercing

- Details

- Category: Tungsten Information

- Published on Thursday, 08 May 2014 11:52

Tungsten alloy armor piercing are weaponry for war. For the destruction of tanks, self-propelled artillery, armored vehicles, armored targets such as ships and aircraft, helicopters, cars, rockets, missile launchers transportation / launch vehicle, command vehicle, communication vehicle, radar and other non-armored metal structure technology weapons.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy rod rotary forging machine swaging

- Details

- Category: Tungsten Information

- Published on Thursday, 08 May 2014 11:43

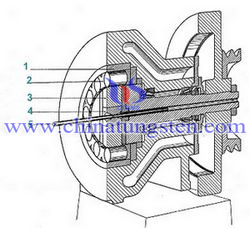

Tungsten alloy rod rotary forging swaging machine is a device, which can be reduced by a mold design tungsten alloy rod diameter mold is designed to about 10,000 per minute impact hammer stick.

Generally, a swager will reduce the diameter of rod about 12% per pass. Swaging elongates the crystals, creating a fibrous structure. Although this is desirable in the finished product for ductility and strength, at this point the tungsten alloy rod must be stress-relieved by reheating.

We provide high quality tungsten alloy swaging rod and Specific lengths and special fabrications can be supplied upon request.

Picture above shows the regular structure of swager for tungsten alloy rod :

1. Hardened Steel Liner

2. Roller Cage

3. Backers

4. Hammers

5. Tungsten Alloy Rod

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod

- Details

- Category: Tungsten Information

- Published on Thursday, 08 May 2014 10:56

The tungsten alloy can be produced in a variety of near-final shapes, but the most frequently encountered shape is that of cylindrical rods, which may be subjected to a series of thermo-mechanical treatments to improve their mechanical properties. For example, tungsten alloy rods are frequently swaged to improve their strength,which results in tungsten alloy swaging rod.

Tungsten alloy swaging rod is made from tungsten alloy rod through swaging which greatly enhance its tensile strength from 1050 MPa to 1200 MPa at least.

Tungsten alloy swaging rod is produced by pressing and sintering tungsten alloy rod into billets, swaging into rod. Smaller sizes of tungsten alloy swaging rod are produced by subsequent drawing. The diameters of tungsten alloy rod through swaging will at 3mm or larger, while if tungsten alloy swaging rod through drawing process, the diameter of it will be below diameters 3mm.

Why Use Tungsten Alloy

Titanium is also popular used materials for producing swaging rod. Titanium's physical qualities of high strength, toughness, durability, corrosion resistance and biological compatibility make it useful in making swaging rod. While titanium's density is much lower which make it difficult in the situation that needing high mass with limited volume.

Tungsten alloy with high density, high melting point, excellent hardness, high tensile strength, high temperature resistance and low vapor pressure is gradually standout among the various swaging rod making materials. What is more, tungsten alloy has superior wearing resistance, prolongs the life of tungsten alloy swaging rod.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Drill Welding Technology Demonstration

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:49

Tungsten carbide drill welding technology demonstration.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

VX-OT Tungsten Carbide Taps

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:43

VX-OT tungsten carbide taps can be processed more than HRC50 material.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com