Why the forging process

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 May 2014 15:49

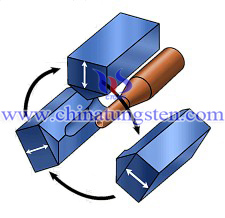

Method of forming forging is regular or irregular use of two or more than two moldaround the workpiece completely or partially reduce the cross-sectional area of a circular predetermined diameter rods or wire.

The forging process is the use of rotary forging machine forging and rolling metal so that the forming, combined machining technology, the plasticity of tungsten alloy rods,in the forging temperature range from 1200 ℃ to 1500 ℃ from. Metal forming process,first by the local deformation gradually expanded to the whole deformation process.

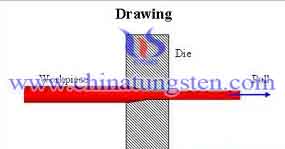

Drawing tools, but also can improve the tensile strength of tungsten alloy rod, tensile strength and prolong the service life of the tungsten alloy rod, increase the value to a large extent.

However, the drawing tools can cause serious problems, more importantly, strength and tensile strength is far better than forging low. After forging, greatly improve the tungsten alloy rod off the power and the tensile strength, improve product performance and prolong the service life and better surface quality of tungsten alloyrod. Forging technology has been widely in the foreign press die instead of drawingtools.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com