Why Use Tungsten Hexachloride Hydrogen Reduction to Prepare Ultrafine Tungsten Powder?

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:53

Why use tungsten hexachloride hydrogen reduction to prepare ultrafine tungsten powder? At present, there are many kinds of preparation methods of ultra-fine tungsten powder at home and abroad, but the most eye-catching method is hydrogen reduction of tungsten hexachloride, according to the experts.

Tungsten Hexachloride Stability

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:52

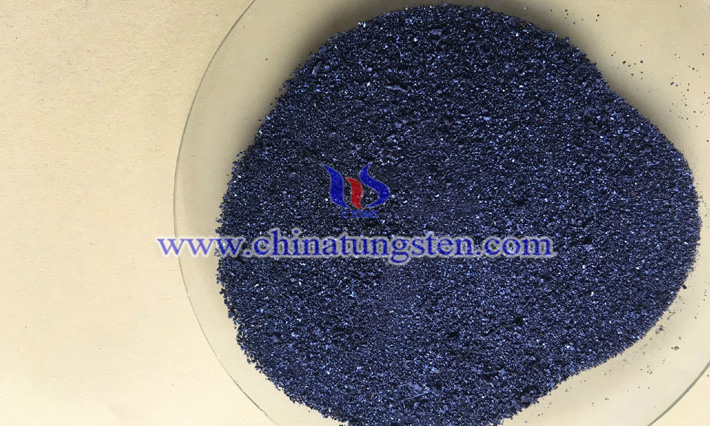

Tungsten hexachloride (WCl6) is known as a dark purple or dark blue fine-grained powder. Well, how about the stability of tungsten hexachloride?

Tungsten Hexachloride Applied for Preparing Tungsten Oxide Mesoporous Material

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:50

Tungsten hexachloride can be applied for preparing tungsten oxide mesoporous material. It has been reported that some researchers use tungsten hexachloride (WCl6) as the source of tungsten and long-chain organics as the template, after gelation in ethanol, the organic template is removed by calcination or solvent extraction agent to prepare tungsten oxide mesoporous material - a functional material with wide application in the fields of catalysis, electrochromism, electrode materials, energy storage and microwave materials.

Tungsten Hexachloride Applied for New Near Infrared Absorbent

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:49

The researchers used tungsten hexachloride (WCl6) and tributyl phosphate to synthesize a new near infrared absorbent. The obtained near-infrared absorber has the advantages of high visible light transmittance, strong near-infrared absorption, and good stability to light and heat. And the researchers also used the near-infrared absorber as a colorant and methyl methionate as a matrix to prepare a new near-infrared filter plastic product with stable near-infrared absorption performance.

Hydrogen Reduction of Tungsten Hexachloride to Prepare Ultrafine Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:19

Hydrogen reduction is the earliest method for preparing rare metals such as tungsten and molybdenum. And the hydrogen reduction of tungsten hexachloride is the most noticeable method in the preparation of ultrafine tungsten powder at home and abroad.

How to Prepare High Purity Tungsten Hexachloride?

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:18

The researchers proposed a method for preparing high purity tungsten hexachloride, which requires the following steps: raw material pretreatment, tungsten hexachloride preparation, tungsten hexachloride refining, condensation reception and tail gas treatment.

What Is Tungsten Hexachloride?

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2020 14:17

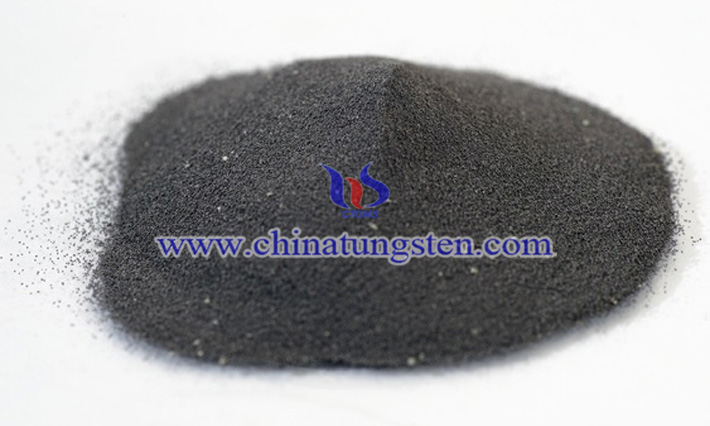

What is tungsten hexachloride? Tungsten hexachloride is the chemical compound of tungsten and chlorine with the formula of WCl6. It shows dark blue or blue violet appearance, and exists as a volatile fine powder under standard conditions.

Ammonium Metatungstate Applied for Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 May 2020 14:28

Ammonium metatungstate (AMT) is an important tungsten-containing compound that can be used as a catalyst in petroleum cracking, organic synthesis, and nitrification reactions. Nowadays, with the rapid development of petroleum refining and petrochemical industries, AMT is more and more popular. Therefore, how to obtain AMT with advantages of low impurity content, stable quality, good solubility, high WO3 content and low cost has become the priority of the current task.

Ammonium Metatungstate Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 May 2020 14:26

Ammonium metatungstate catalyst is a new type of catalyst with the characteristics of strong activity, high selectivity, long service life, good water solubility, uniform distribution of active components on the carrier, and large specific surface area. Therefore, it has attracted much attention form many researchers, and its applications are expanding.

Ammonium Metatungstate Decomposition Temperature

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 May 2020 14:25

Ammonium metatungstate decomposition temperature varies with the degree of completion of the decomposition reaction. This also means that ammonium metatungstate will produce different products at different decomposition temperatures.

sales@chinatungsten.com

sales@chinatungsten.com