Carbon Nitride-Tungsten Oxide Composite Hollow Microspheres

- Details

- Category: Tungsten Information

- Published on Monday, 22 July 2019 22:27

Tungsten oxide inorganic semiconductor materials have been applied in photocatalysis, photochromism, gas sensitivity, electrochromism, and field emission due to their unique physical and chemical properties. Researchers can prepare tungsten oxide micro-nanomaterials with different sizes and morphologies, such as nanosheets, nanorods and hollow spheres.

As an n-type semiconductor, tungsten oxide has a certain photocatalytic activity. Its narrow band gap can make it excited by visible light. The upper edge of its valence band (VB) is close to that of titanium dioxide, which exceeds the oxidation potential of hydrogen peroxide/oxygen. However, due to the low conduction potential of tungsten oxide, photogenerated electrons are easy to react with oxygen in the air, resulting in its light. Decrease in catalytic activity. In order to further improve the physical and chemical properties of tungsten oxide, tungsten oxide has become a research hotspot in recent years through morphology control, element doping and compounding with different semiconductor materials.

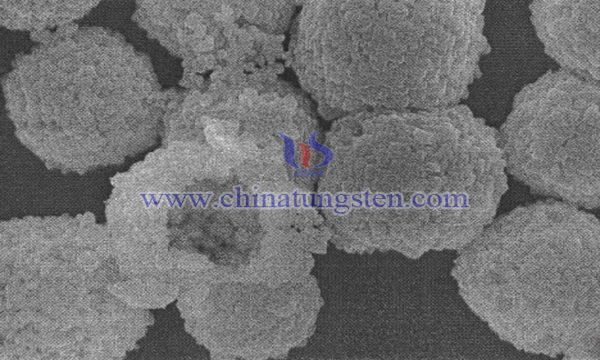

Hollow sphere tungsten oxide has attracted much attention due to its unique morphology. It has high specific surface area, excellent load-bearing capacity and low density. Some scholars have proposed a method to prepare carbon nitride-tungsten oxide composite hollow microspheres. The microspheres have high specific surface area and good visible light responsiveness. The specific steps include:

0.330 g (1.0 mmol) of Na2WO4·2H2O, 4.504 g (25 mmol) of glucose and 0.336 g (8 mmol) of monocyanamide were dissolved in 50 ml deionized water. Ultrasound was used to stir for 30 minutes to form a uniform solution. The above mixed solution was transferred to stainless steel hydrothermal kettle, and heated in muffle furnace at 2 ℃/min to 200 ℃ for 20 hours. After natural cooling, centrifugation, repeated washing with distilled water and absolute ethanol for three times, vacuum drying at 60 ℃, WO3-CN composite carbon spheres were obtained. The composite carbon spheres were heated to 500 ℃ at 2 ℃/min in a tubular furnace, burned for 2 hours and cooled naturally. Finally, the carbon nitride-tungsten oxide composite hollow microspheres were obtained.

The prepared carbon nitride-tungsten oxide composite hollow microspheres have hollow inner cavity, and the shell is composed of carbon nitride and tungsten oxide in a certain proportion, showing good homogeneity. The hollow microspheres have larger specific surface area. The hollow inner cavity can provide more electromagnetic wave transmission and reflection paths, and improve the material's radiation energy to the outside world. The capacity of absorption and utilization can be applied to photocatalytic degradation of pollutants, photovoltaic cells, solar cells and other fields.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com