Tungsten Gold-plated Chopsticks For Wedding Gifts

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:47

- Written by yaqing

- Hits: 838

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gold And Tungsten Gold-plated Products Maintenance Precautions

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:44

- Written by yaqing

- Hits: 308

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Effect of Powder Property on Tungsten Copper Electrode Density (1 of 2)

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:00

- Written by xiaobin

- Hits: 261

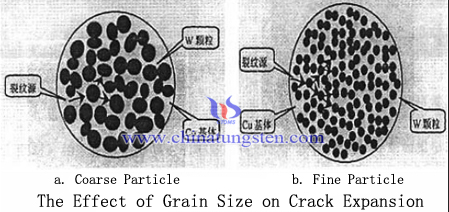

Too fine granularity of tungsten powder has bad heat shock resistance, it is easily to produce cracks when arcing, which decreases the hardness and the density of contacts and increases the resistivity. In addition, in the electric arc, the gap at the easy to crack, copper-rich copper areas prone ablation spatter, even vaporization, forming a contact surface cavities, pits and cracks and other defects. Too coarse tungsten powder, on the one hand will decrease the contact area of tungsten powder particles, in the process of sintering tungsten framework between tungsten powder particles can not form a good bond necking, it is difficult to form a high strength tungsten skeleton. This further influenced the subsequent sintering process combined with weaker intensity tungsten framework by liquid copper erosion leaving the bonding strength further reduced, resulting in decreased tungsten copper W-Cu electrode contact material hardness.

Tungsten powder granularity has a great influence on hindering the cracks expanding. Smaller particle size tungsten powder, tungsten particles dispersed after sintering. When the micro crack copper matrix and tungsten particles, tungsten particles will encounter more, every encounter, micro crack bifurcation occurs, thereby increasing the crack propagation energy consumption. Thus, the dispersed tungsten powder can be more effectively suppressed crack propagation, the tungsten copper electrode material bonding strength has been significantly improved. On the other hand, tungsten powder particle size is too coarse, the tungsten skeleton pore becomes large, easy to cause evaporation under arcing splashing copper electrode degree of burning increases, leading to a galvanic corrosion rate is increased. It is a good way to get tungsten copper electrode material with excellent properties that use different granularity of tungsten powder matched.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Air Curtain Counterweights

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 17:42

- Written by yaqing

- Hits: 299

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

New Types and Structure of Coated Cemented Carbide——Diamond Coating (1 of 3)

- Details

- Category: Tungsten Information

- Published on Friday, 08 January 2016 16:57

- Written by xiaobin

- Hits: 242

As we know, diamond is the hardest material in the world so far. It has high density (3470-3560kg/m3), high hardness (Mohs’ scale of hardness is 10), high melting point (3550℃-4000℃). Although diamond has stable chemical property and excellent wear resistance, it is difficult to manufacture the required parts or products directly. Therefore, diamond coating by CVD (Chemical Vapor Deposition) can effectively solve the problem, which is widely used in the mould of metal wire processing. Diamond coating deposits a layer of polycrystalline diamond film on tungsten carbide matrix mainly by low pressure chemical vapor deposition (LPCVD), it can remarkably improve the hardness and wear resistance of tungsten carbide.

Take the consumables of metal wire as an example, drawing die mainly includes two kinds that tungsten carbide mould and polycrystalline diamond mould in the wire industry, while the quality, the efficiency and the comprehensive properties of metal wire is greatly determined by the properties of drawing die. Tungsten carbide mould has good hardness and toughness, the production cost is lower than polycrystalline diamond, but it is easily adhered by compounds so that its service life is shorter than polycrystalline diamond; polycrystalline diamond has excellent hardness and wear resistance, and it has higher mould cost, it is difficult to manufacture the larger size and abnormal mould, which has lower plasticity and toughness. Diamond coated cemented carbide mould by LPCVD not only combines with both advantages of diamond and tungsten carbide, but also overcomes the defects of them, which is one kind of the most widely used new drawing die. The sketch of drawing die working as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com