What Is Soft Tungsten Gold?

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:44

- Written by yaqing

- Hits: 266

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Difference Between 18K Tungsten Gold-plated And 18K Gold

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:42

- Written by yaqing

- Hits: 291

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Coated Cemented Carbide Types——Gradient Coating (1 of 2)

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:09

- Written by xiaobin

- Hits: 264

Since coated cemented carbide developed, coating types were diverse, such as single-layer coating, multi-element composite coating, gradient coating, nano coating, super-hard coating and soft coating.

3. Gradient Coating

Due to the differences of friction factor and coefficient of thermal expansion between coating layer and the matrix, if it can not be effectively controlled, the binding force of coated cemented carbide will remarkably decrease. Gradient coating solves the problem perfectly, which has structural composition and micro-structure in the space. It can reduce the concentration of the stress, eliminate the surface of multi-layer, which improves the binding strength of coating layer and matrix, and extends the service life of coated cemented carbide.

It can be found that gradient coating has better micro-hardness and toughness by analyzing the section structure and composition distribution of gradient Ti(C,N) coating layer. The related researcher adopted magnetron sputtering to deposit gradient TiAlN coating on tungsten carbide matrix, and injected Ti atom between the gradient coating and the matrix by metal vapor vacuum arc (MEVVA), which formed a transition layer with a certain concentration of Ti. After that this kind of tungsten carbide with gradient coating performed perfectly in the test of dynamic impact, and has better wear resistance and toughness in high-speed cutting or milling and been a giant leap in the service life.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Coated Cemented Carbide Types——Gradient Coating (2 of 2)

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 17:12

- Written by xiaobin

- Hits: 260

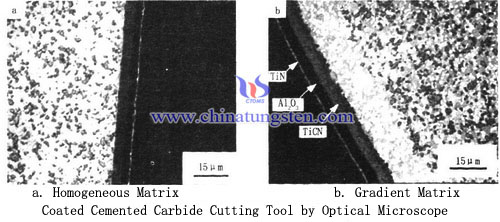

It is necessary to compare with gradient tungsten carbide. Gradient coating refers to gradient arrangement in coating structure, while coated cemented carbide is not only determined by the coating material, the more closely related to the properties of tungsten carbide matrix. Tungsten carbide matrix with gradient structure effectively solves the problem that the cracks of coating layer extend to tungsten carbide matrix. It adds a spot of TiN, (Ti,W)C and some phase with cubic structure in WC-Co system, and adopts nitrogen removal process to form no cubic phase and Co binder phase concentration with gradient structure, which has excellent toughness and in case of the cracks expanding to some extent. There is homogeneous tungsten carbide matrix and tungsten carbide with gradient structure pictures under optical microscope as follow:

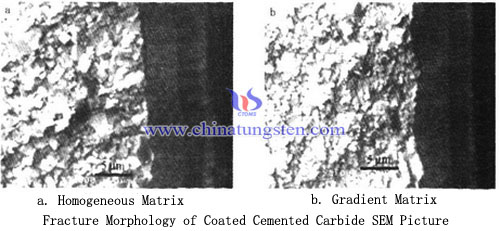

It is distinct that there is a big difference between homogeneous tungsten carbide matrix and gradient structural tungsten carbide matrix. In addition, compared with the fracture morphology of coated cemented carbide cutting tool SEM (Scanning Electron Microscope) picture:

Viewed from the fracture morphology of coated cemented carbide SEM picture, we can find that the fracture morphology of tungsten carbide cutting tool with gradient structure is coarser and unevener than homogeneous tungsten carbide cutting tool. Due to high toughness of Co concentration, it can absorb almost energy of cracks expanding, which increases the plastic deformation. It proves that tungsten carbide with gradient structure has better impact resistance toughness and cutting edge toughness.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

China Tungsten Resource Characteristics

- Details

- Category: Tungsten Information

- Published on Thursday, 07 January 2016 11:53

- Written by xinyi

- Hits: 240

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com