Sodium tungstate concentration on Ni-Co-W-P alloy coating influence 1/2

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 January 2016 18:34

With the development of medical technology, nickel titanium shape memory alloy stent and stainless steel stents has been used in clinic. But this kind of bracket has some drawbacks. In this paper, on the bracket plating a layer of magnetic thin films, the preparation can be magnetized medical metal stents. Near plus a magnetic field is used to change the drugs to tumor cells, increase the function of stent chemical drugs, reach the role of local targeted therapy, and reduce the side effects of drugs.

There are many preparation methods of magnetic thin film. Because the bracket is made of nickel - titanium wire or stainless steel wire, complex shape, the first choice is the chemical plating method. Chemical plating has low cost, simple operation and uniform coating, and low porosity. This paper mainly discusses the Ni Ti shape memory alloy stent - table and electroless Ni-P-Co-W magnetic thin film in the formula of sodium tungstate concentration of Co-W-Ni-P film morphology and performance.

There are many preparation methods of magnetic thin film. Because the bracket is made of nickel - titanium wire or stainless steel wire, complex shape, the first choice is the chemical plating method. Chemical plating has low cost, simple operation and uniform coating, and low porosity. This paper mainly discusses the Ni Ti shape memory alloy stent - table and electroless Ni-P-Co-W magnetic thin film in the formula of sodium tungstate concentration of Co-W-Ni-P film morphology and performance.

By chemical plating, test and analysis, we can draw the following conclusions:

1. Sodium tungstate affects deposition of W:

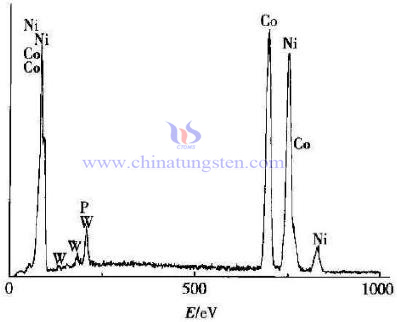

With the increase of mass concentration of sodium tungstate, deposition of W mass fraction increased as well. Metal Ni and Co in the coating is the main body elements, with the increase of mass concentration of sodium tungstate, irregular mass fraction of their change. P mass fraction is less.In sodium tungstate concentration is 0.8 g/L EDS spectrum analysis of coating.

2. Sodium tungstate affects coating gloss and adhesion:

Use JS28 type microscope, in different mass concentration of sodium tungstate solution of coating gloss, 90 ° bend test coating on the number of crack and spalling blocks were observed after evaluation. Coating gloss and adhesion test results show that the change in the plating solution mass concentration, sodium tungstate coated gloss and adhesion to significantly alter. When the concentration of sodium tungstate quality control in 0.4 ~ 1.0 g/L, the deposition of the luster and binding force is relatively good.

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com