Sodium tungstate concentration on Ni-Co-W-P alloy coating influence 2/2

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 January 2016 18:37

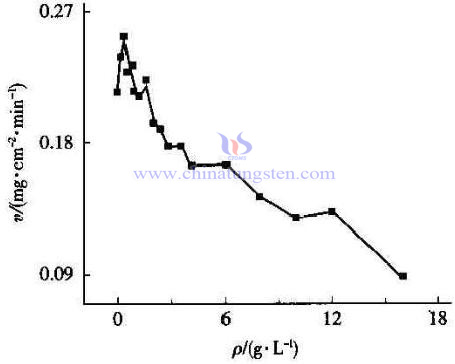

Influence of sodium tungstate on deposition rate: when the concentration of the quality of sodium tungstate solution is small, plating speed rises with the increase of concentration. Mass concentration in the 0.4 g/L plating velocity, concentration of sodium tungstate quality continues to increase, plating speed, began to appear the obvious downward trend. The change rule, add a small amount of sodium tungstate in plating solution, deposition has a promoting effect of plating solution, but the quality of sodium tungstate concentration exceeds a certain value, accelerated the decomposition of the plating solution, deposition rate declines.

Influence of sodium tungstate on magnetic property: chemical plating solution mass concentration of sodium tungstate had significant effect on the magnetic coating, with the increase of mass concentration of sodium tungstate, thin film of coercive force decrease after rising first, peaked at 0.4 g/L. Sodium tungstate concentration on the influence of saturation magnetization intensity and its influence on coercive force trend similar to that of low concentration with the increase of mass concentration of sodium tungstate, coating of the saturation magnetization increased, and at the age of 0.8 g/L reached its highest 22 emu/g, then a downward trend. W mass fraction in the coating increased with the increase of mass concentration of sodium tungstate, so sodium tungstate mass concentration of magnetic can be attributed to the influence of W on the influence of coating microstructure and composition.

Influence of sodium tungstate on magnetic property: chemical plating solution mass concentration of sodium tungstate had significant effect on the magnetic coating, with the increase of mass concentration of sodium tungstate, thin film of coercive force decrease after rising first, peaked at 0.4 g/L. Sodium tungstate concentration on the influence of saturation magnetization intensity and its influence on coercive force trend similar to that of low concentration with the increase of mass concentration of sodium tungstate, coating of the saturation magnetization increased, and at the age of 0.8 g/L reached its highest 22 emu/g, then a downward trend. W mass fraction in the coating increased with the increase of mass concentration of sodium tungstate, so sodium tungstate mass concentration of magnetic can be attributed to the influence of W on the influence of coating microstructure and composition.

Influence of sodium tungstate on coating microstructure: through the coating obtained by different concentration of sodium tungstate quality SEM analysis, the results show that the addition of sodium tungstate can improve coating morphology. With sodium tungstate mass concentration increasing, cellular density, uniform, fine particles, growing more mature. Sodium tungstate concentration continued to increase, the morphology change, coating surface trench, uneven grain size and large cellular processes, local caking and micro cracks have appeared.

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com