Tungsten Crucibles Are Used in the Preparation of Superalloys

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:09

In the field of modern high-end manufacturing, superalloys are widely used in aerospace, gas turbines, nuclear industry and high-temperature chemical industries due to their excellent high-temperature strength, oxidation resistance and corrosion resistance.

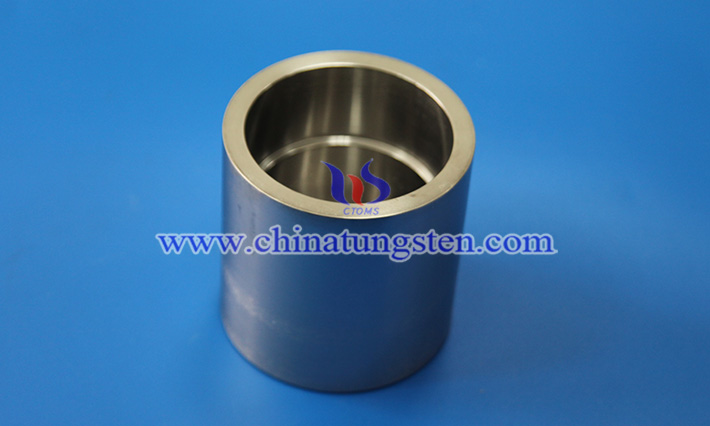

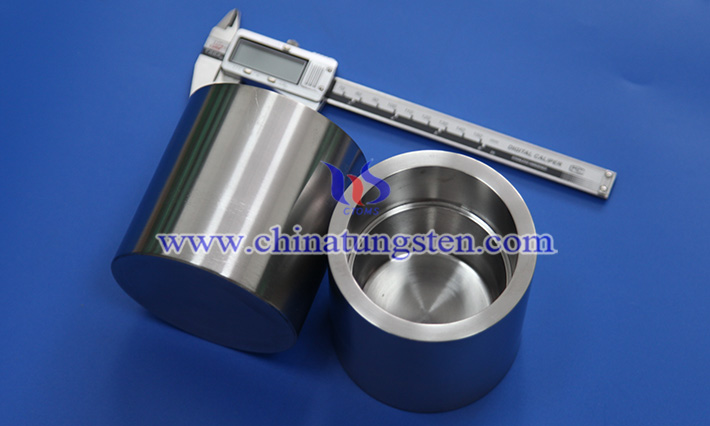

In order to prepare superalloy materials with excellent properties, uniform structure and stable composition, processes such as melting, alloying, casting and refining are often required at extremely high temperatures. Tungsten crucible, as a metal container with extremely high melting point and excellent chemical stability, has become an indispensable key component in the preparation of superalloys.

First of all, the most significant advantage of tungsten is its extremely high heat resistance, which can withstand operating temperatures well above 2000°C without deformation, melting or structural failure. In the melting process of many superalloys, such as nickel-based, cobalt-based, molybdenum-based or tantalum-based alloys, the melting temperature is usually between 1400~1800°C. While metal or ceramic containers are prone to soften or react in this temperature range, W crucibles can work stably for a long time to ensure the safety and continuity of high-temperature processes.

Secondly, superalloys have very strict requirements for precise control and purity of alloy composition. When the alloy is melted at high temperatures, the chemical reaction between any container material and the melt may introduce impurities, affecting the mechanical properties, thermal stability and corrosion resistance of the final material. Tungsten has very low vapor pressure and excellent chemical inertness, and does not react easily with molten metal in an inert gas or vacuum atmosphere. This stability allows crucibles made of tungsten to provide a highly clean processing environment for superalloys, minimizing contamination of impurities and migration of elements.

In addition, it also has excellent thermal conductivity and mechanical strength, and is especially suitable for high energy density melting methods such as arc melting, electron beam melting (EBM), and plasma melting (PAM). In these processes, local temperatures rise dramatically, requiring the crucible to transfer heat quickly to achieve uniform fusion of alloy components, while having sufficient structural strength to withstand melt weight and thermal stress. The W crucible exhibits excellent performance in this regard and is particularly suitable for process occasions that require the preparation of high-uniformity, high-density alloy ingots.

Tungsten crucibles are also widely used in the preparation of refractory metal alloys, such as tungsten-rhenium alloy (W-Re), tantalum-hafnium alloy (Ta-Hf) and the melting of some special cemented carbide master alloys. These alloys have extremely high service temperatures and are widely used in key parts such as rocket nozzles, high-temperature molds, and electric heating elements, and their preparation process requires more stringent performance requirements for container materials. The high melting point and low dissolution characteristics of W crucibles are just enough to meet the melting needs of this class of high-end materials.

Of course, there are some usage limitations. For example, tungsten is susceptible to oxidation in an oxidizing atmosphere to form volatile tungsten oxide (WO₃), which can lead to brittleness of crucibles. Therefore, the atmosphere conditions must be strictly controlled in the process of use, and the vacuum system or the inert atmosphere filled with argon and helium is generally used to protect the environment. At the same time, tungsten material processing is difficult and relatively expensive, and the service life and recycling of the crucible also need to be comprehensively considered.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com