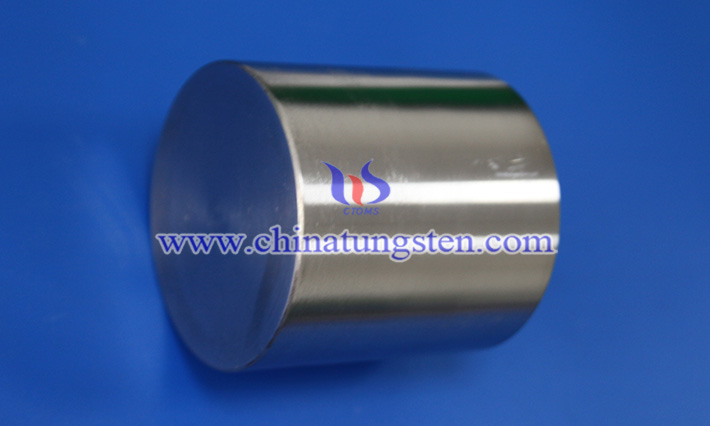

Tungsten Crucibles Are Used for Vacuum Heat Treatment

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:11

Vacuum heat treatment is a process of heating and cooling metals or alloys under high vacuum or protective atmosphere, and is often used to improve the mechanical properties, dimensional stability and surface quality of materials.

Compared with traditional heat treatment methods, it has significant advantages, such as preventing oxidation and decarburization, improving treatment cleanliness, reducing heat treatment deformation, etc., so it is widely used in aerospace, precision instruments, mold manufacturing and high-end electronics industry. As a key component for carrying high-temperature metals or alloys, tungsten crucibles play an important role in this process.

Tungsten is a metal with an extremely high melting point, low vapor pressure, and excellent thermal stability, which exhibits excellent structural stability in high-temperature vacuum environments. It is by taking advantage of these properties that crucibles are widely used in high-temperature processes such as melting, sintering, annealing and alloying in vacuum heat treatment processes. Since vacuum heat treatment is usually carried out between 1100°C and 2000°C, which places extremely high demands on the heat resistance and chemical inertness of the container material, this crucible is one of the few materials that can maintain long-term stable operation under such extreme conditions.

In a vacuum environment, traditional metals such as stainless steel and nickel-based alloys are prone to volatilization or reaction with the treated material at high temperatures, resulting in metal contamination or uncontrolled alloy composition. Tungsten is chemically stable in a vacuum or inert gas environment, and will not react with most metals or gases even above 2000°C, which greatly guarantees the purity of the heat treatment process. For example, when processing reactive metals such as titanium, molybdenum, and tantalum, tungsten crucibles can prevent these materials from adsorbing oxygen, nitrogen, or carbon at high temperatures, thereby maintaining their chemical purity and properties.

The crucible also has excellent thermal conductivity and thermal shock stability, which allows it to respond quickly to heating or cooling operations in heat treatment equipment, effectively improving heat treatment efficiency and reducing material deformation or cracking caused by uneven temperatures. In addition, the high density and strength of tungsten allow it to withstand the weight of workpieces or melts at high temperatures without structural collapse, making it particularly suitable for vacuum processing of large or high-quality workpieces.

Typical applications include:

High temperature annealing: used for vacuum annealing of molybdenum, titanium, niobium and other metals to eliminate internal stress and improve microstructure uniformity and dimensional stability;

Vacuum sintering: suitable for densification of cemented carbide, ceramics and powder metallurgy products to improve the mechanical properties of materials;

Vacuum alloying: used for the smelting and mixing of high-performance alloy materials, especially in vacuum electric arc furnace, electron beam furnace and other equipment, W crucible is an important melt pool vessel;

Thermal Cleaning & Degassing Treatment: Certain electronic components and high-purity materials are heated under vacuum to remove impurities and gas adsorption layers, and W Crucible provides a stable and pollution-free environment.

Despite the many advantages of the W crucible, it is still necessary to pay attention to the protection conditions in its practical use. For example, in an oxygenated environment, tungsten is susceptible to oxidation to form tungsten oxide (WO₃), which sublimates at high temperatures, reducing the service life. Therefore, tungsten crucibles are usually only used in high vacuum or in environments protected by inert gases (e.g. argon, helium) to avoid oxidation losses. In addition, due to the difficulty and high price of tungsten material itself, its use and maintenance costs also need to be considered in the overall process.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com