The Manufacturing Process of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:12

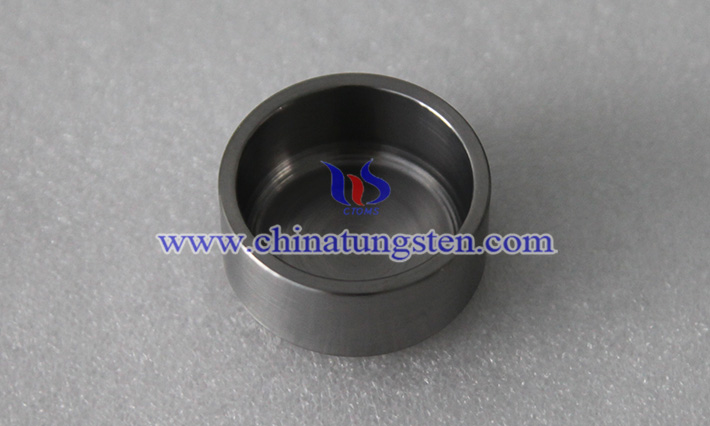

The manufacturing process of tungsten crucible is complex and the technical requirements are high, mainly including powder preparation, pressing molding, high-temperature sintering and mechanical processing.

1. Preparation of raw materials

The manufacture of crucibles begins with the preparation of high-purity tungsten powder. Tungsten powder is usually obtained by hydrogen reduction of tungstate, such as sodium tungstate or ammonium tungstate. High-quality crucibles have extremely high requirements for the purity of raw materials, usually requiring tungsten powder purity of more than 99.95% to reduce oxidation, volatilization or structural embrittlement caused by impurities during high-temperature use. The particle morphology, particle size distribution and loose density of tungsten powder will also directly affect the quality of subsequent pressing and sintering, so strict screening and pretreatment are required.

Second, the molding process

After drying, mixing and sifting, tungsten powder is loaded into a mold for cold isostatic pressing (CIP) or compression molding. The isostatic pressing method presses the green body through uniform pressure in all directions, making its internal structure dense and strong, especially suitable for the manufacture of large-size or thick-walled crucibles. Molding is mostly used for the initial forming of small crucibles or complex geometries. At this stage, the pressed "green billet" does not yet have sufficient strength and needs to be further densified by high-temperature sintering.

3. High-temperature sintering

The pressed green crucible is sintered in a high-temperature hydrogen atmosphere. The sintering temperature is generally above 2000°C, and it is usually carried out by medium frequency induction sintering furnace or vacuum sintering furnace. In the sintering process, tungsten powder particles are diffused, recrystallized and bonded to form a continuous dense grain structure, which significantly improves the mechanical strength and high temperature resistance. Atmosphere control in the high-temperature sintering process is crucial, and the intrusion of impurity gases such as oxygen and nitrogen must be strictly prevented to ensure the purity and corrosion resistance of the finished crucible.

4. Machining and surface treatment

The sintered crucible is a "rough billet", the size and shape have not yet met the requirements for use, and the final dimensional accuracy and surface quality must be achieved through precision machining. Tungsten has high hardness and brittleness, which makes it difficult to perform conventional machining (such as turning, milling, and drilling), so special carbide tools, low-speed cutting, and cooling and lubrication matching processes are required. In addition, in order to improve the oxidation resistance and service life of the crucible, some high-end applications will also use post-treatment processes such as surface polishing, electrolytic polishing or coating of protective layers (such as molybdenum layer and nitriding layer).

5. Quality inspection and packaging

After the manufacture of the crucible is completed, it needs to go through a series of strict quality inspection procedures, including dimensional accuracy testing, density testing, metallographic structure analysis, impurity element analysis and vacuum leakage testing. The density usually needs to reach more than 98% of the theoretical density, and there are no cracks, impurities or structural defects on the surface to meet the requirements of high temperature and vacuum environment. Finally, qualified tungsten crucibles are vacuum-sealed or packaged with inert gas to prevent oxidation or contamination during transport and storage.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com