About Doped Tungsten Models

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:08

Doped tungsten wire , also commonly known as anti- sag tungsten wire, tungsten, aluminum , tungsten, its main feature is added in the dispersion strengthening elements potassium , forming a " dovetail lap " -shaped interlocking internal grain structure, and thus improved resistance to high temperature creep resistance tungsten .

Doped tungsten complete production line including blue tungsten reduction from APT to the addition of modified elements potassium, aluminum , silicon , and then sintering melt down , rotary forging process , coarse and fine tungsten filament in each step of the process . W31, W61, W91 , and WR15 new high-temperature tungsten filament :

W31

It has as excellent high temperature performance, reeling performance , to meet the energy-saving lamps , fluorescent lamps production use, Weihai polycrystalline material in 5 kg to provide a single , suitable for change pull factory. Grades from Japan , therefore , corresponds to the early use of filament capsule of the user.

W61

Equivalent grades of tungsten in Japan W31 performance and use, provides a single Weihai polycrystalline material in 5 kg , the same change for pulling factory. Grades from China's latest national standards.

W91

With excellent high temperature performance, can be used for high and low voltage halogen lamps , vehicle lights and high performance requirements of high prices on the tube and other fields.

WR15

It's a high -grade , high temperature, high shock tungsten wire, high temperature performance superior W91 grades for high color temperature , energy-efficient ( up C-class energy efficiency standards ) halogen incandescent lamp , is the material of choice for export to EU .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Lanthanum-Doped Tungsten Micro Advantages and Positive Effects

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:05

Lanthanum -doped tungsten micro advantages and positive effects are :

1 Lanthanum -doped tungsten is added to a small amount of tungsten -doped lanthanum , changed the composition of doped tungsten , lanthanum doped tungsten micro cold resistance , heat resistance and other physical characteristics were compared with the conventional tungsten -doped greatly improved, the tests showed that micro- doped lanthanum tungsten cold, heat resistance than conventional doped tungsten are increased by 5 to 7%.

2 , The use of pressure guns lanthanum acid ammonia solution in spray form to be placed in the pot dopant doped tungsten blue spray , can effectively control the addition amount of lanthanum , tungsten is reached improve performance purposes , but also effectively reduce production costs, improve economic efficiency of enterprises .

3 , Increases in the later process of flame oxidation in air annealing step , the processing can effectively eliminate the hardened alloy , the alloy during processing to eliminate the internal accumulation of stress , tensile strength, lower tungsten , the tungsten wire the manufacturing more convenient.

4 , The production of micro- doped lanthanum by the addition of a small amount of tungsten lanthanum , thus changing the composition of the doped tungsten and internal grain size while eliminating the micro by oxidation annealing stress within tungsten doped lanthanum , therefore produced tungsten has a good seismic performance. Tests showed that using this method of production of micro- lanthanum -doped tungsten produced each 10 14V0. 1A0. 7CP bulbs, tungsten specifications for the 1. 0mg/200mm and 1. Ang/200mm, doped with tungsten in the same general seismic tests carried out under the conditions of contrast , the result is a specification of 1.2mg / / 200mm light bulbs, ordinary doped tungsten average number is 673 times the impact resistance , resistance to micro- doped lanthanum tungsten average impact of the number of 1233 ; specifications for a . 0mg/200mm bulbs , ordinary doped tungsten average number of 680 times the impact resistance , while the micro- doped lanthanum tungsten average number of impact-resistant 1209 times.

5, With a simple process, easy to implement and the advantages of low production costs , while the production of micro- lanthanum -doped tungsten has a long life , optical performance, strong seismic performance and a light bulb filament sag after use small amount of features.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micro-Doped Lanthanum Tungsten Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 15:00

A micro- lanthanum -doped tungsten preparation method comprises the following steps :

( 1 ) The paratungstate in high purity hydrogen reduction furnace in pre- reduced blue tungsten ;

( 2 ) Wet incorporation of potassium silicate , aluminum nitrate solution , dried by stirring the mixture , the potassium, silicon, aluminum, tungsten adsorbed in the gap to obtain a doped tungsten blue ;

( 3 ) The use of pressure guns lanthanum acid ammonia solution in spray form to place the doped tungsten blue spray doping pot while stirring , until after spray drying, to obtain amino acid lanthanum doped tungsten blue ; < br />

( 4 ) The blue tungsten doped lanthanum acid into ammonia reduction furnace in high purity hydrogen reduction reaction to obtain a reduction of lanthanum tungsten alloy coarse powder ;

( 5) Reducing the tungsten alloy powder of lanthanum quantitative hydrochloric acid, hydrofluoric acid washing to remove the excess dopant and other impurities to obtain lanthanum tungsten alloy powder ;

( 6 ) Using isostatic press kit to install the elastic modulus of lanthanum tungsten alloy powder is applied to the equal force , made of uniform density tungsten billet ;

( 7 ) Hydrogen tungsten billet under the protection of pre- sintered to obtain a pre-sintered article ;

( 8 ) Pre-sintered in hydrogen under the protection of vertical melt sintering , melting sintering get vertical bar ;

( 9 ) Using the swaging equipment carried on the vertical melt sintering of forging, sintering of the vertical melt gradually reduced cross-section , the length increases, billet within the organizational structure of the tungsten grains and surface condition changes state to prepare tungsten rod ; < br />

( 10 ) Annealing the tungsten rod ; ( 11 ) the annealed then swaging tungsten rod having a diameter of 3.7mm tungsten rod ;

( 12 )On the turntable for coarse tungsten rod tension , tungsten rod through the die holes turntable after the cross section is reduced, increase in length , to obtain a crude tungsten wire ;

( 13 ) The crude tungsten in air by flame oxidation anneal , and after the coating of graphite and a small compression ratio, single stretch, eliminate work hardening and reduce the tensile strength filament ;

( 14) The crude tungsten single stretched via a plurality of the desired motif is drawn into thin tungsten wire. Moreover , in step ( 7 ) in the pre-sintering temperature of 1200 ~ 1400 ° C, sintering time 30 to 50 minutes.

Moreover , in step ( 3 ) in the vertical melt temperature of the final sintering sink 50 ~ ^ 50 ° C, the sintering time is 60 to 70 minutes to obtain the vertical melt density of sintered article 17. 2 ~ 17. 6g/cm3.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Potassium-Doped Tungsten Bulbs Basic Content of Reinforcement Theory

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:56

Potassium foam reinforcement theory of the basic content includes three interconnected parts, which are :

(1) Potassium bubble formation and control. Tungsten oxide is added in trace potassium silicate , aluminum chloride mixed aqueous solution with hydrogen reduced to metal powder , and then compacts , sintering billet . Billet to form a large number of non-uniform distribution of the doping hole φ0.1 ~ 0.4μm . Analysis confirmed that potassium at room temperature to solidify the doped ionic pore walls , and tungsten have a coherent relationship . In the following rotary forging temperature , cold drawing and heat treatment process, the potassium -doped hole is flattened , elongated form along the filament axis orientation distribution of the " K tubes " or " K -line ." The greater the deformation process , the greater the aspect ratio of potassium tube . When annealed tungsten , potassium pipe expansion due to vaporization of potassium ( K boiling point of about 760 ℃), the temperature rose further instability potassium tubular shape , a split of the ovule , a bunch of potassium ordered bubble columns. Potassium tube split ovule instability of the process can be seen as a cylinder instability and approximate equation with perturbation theory and its potassium bubble dispersion model to establish quantitative expression equation, namely the establishment of the aspect ratio of potassium tube and the degree of deformation relationship L / W = (0.75 ~ 1.3) (Do / Dk) 4, ( wherein L, W, Do, Dk namely potassium tube length , width, diameter and tungsten rod original diameter after processing ) , and after dispersion derived The basic parameters of potassium bubble columns : bubble diameter potassium , potassium -containing foam bubble column number and spacing between two adjacent bubbles . Electron microscopic observation and experiment results calculated as consistent with each other . Experimental results and long-term production practice have shown that the necessary amount of potassium- doped hole is to ensure that the basis of potassium bubble dispersion , it depends on the additive potassium -doped tungsten optimum content ; while potassium and potassium bubble pipe split orderly diffusion model can control the degree of deformation and heat treatment through the system to reach . This design -doped Si, Al, K , and a reasonable amount of added processing to develop a reasonable degree of deformation and heat treatment system provides a credible scientific basis .

( 2 ) Potassium soak in the process of recrystallization behavior and mechanism of action . Along with the wire axis parallel to the direction of the ordered arrangement of potassium -doped tungsten bulb is caused by recrystallization behavior -specific basis . General material at an appropriate temperature after recovery and recrystallization processes , the formation of equiaxed grains without deformity . However , at high temperature to form doped tungsten filament axis direction along the particular aspect grow large particles , even cross-section of the wire is covered with 1 to 2 grains . It is this special grain boundary growth and finger overlapping grains , the tungsten doped with excellent high-temperature creep resistance , or anti- sag properties of tungsten . Ordered along the filament axis parallel to the direction of the distribution of potassium bubble column, a high temperature high vapor pressure within the bubble to bubble K corresponds to the second phase particles , strong pinning the grain boundary ( see Figure 1 ) , So a aspect suppress recrystallization , improves the recrystallization starting temperature , on the other hand to hinder the grain boundary migration radial filaments , and force it to move the wire axis , thus forming a special aspect of great growing grains ( see Figure 2 ) . The potassium bubble behavior and grain growth model has been a large number of experimental observations and theoretical calculations confirmed, but the details of its recrystallization processes and mechanisms are still not fully unified understanding. The focus of disagreement reply , primary and secondary recrystallization phasing and specific growth or soaring mechanism . Most people think that the first stage of recrystallization primary recrystallization in deformed grains gradually formed simultaneously coarse wire axis parallel to the series as the main feature of potassium bubble , but some people think it is the processing state of the Asian crude fiber bundles crystal ( see sub-structures ) polymerization grew up belonging to a polygon or restoration process . It was also defined as the in-situ re -crystallization process, the formation of the rod or sub-grain ; recrystallization grains elongated second stage is called overgrowth rapid growth or even covered wire cross-section of the main feature. However, this process is defined as the primary or secondary recrystallization still significant differences. Chinese scholar and his research group left Tieyong learn various scholars in the analysis based on the results , after years of systematic experimental and theoretical analysis , published a series of papers presented doped tungsten recovery and recrystallization nucleation mechanisms and recrystallization growth mechanism . The basic conclusion is that : first, the tungsten -doped high-temperature annealing occurs when deformed grains ( or fibers ) change phenomenon , is to resume the process of a special organizational change , grain boundary dissociation , Asia fiber aggregation caused by not once again crystallization behavior ; Second, because potassium bubble column grain boundaries and dislocations movement and its direction is strong pinning effect , resulting in a sub- fiber polymerization process proceeds very slowly and can be extended to temperatures above 2000K ; Third , doping the formation of abnormal grain growth in tungsten seemingly secondary recrystallization soaring organization, but experimental observations and theoretical calculations show that it is not the primary recrystallization occurs in a small number of matrix grain growth resumed , nucleation of new grains crystal growth and annexation of a few large new small recrystallized grains , and several other processes occur almost simultaneously complex process , based on deformation energy storage, grain boundary energy as the driving force , at different stages driven results can not simply traditional defined as the secondary recrystallization process .

( 3 ) Potassium bubble dispersion strengthening mechanism . Enhanced in a variety of materials, methods, dispersion strengthened (DS) is a second- phase strengthening , strengthening effect depends on the second phase of its chemical and thermodynamic stability , the ideal shape , small size , enough quantity and good dispersion . As a second phase of potassium bubbles all the conditions with the above , plus the size of the bubble and the dispersion K mode is controlled , but also shows the superiority of potassium bubbles , it has been classified as a number of dispersion strengthened in a distinctive strengthening mechanism . The second phase dispersion strengthened explain theoretical model matrix lot more is Orowan (Orowan) mechanism . Potassium bubble second phase particles as a special addition to causing diffusion rate decreases , increase the recrystallization temperature and thermal processing generate stable fibrous tissue and dislocation structures such as these Orowan strengthening indirectly strengthening mechanism , it must also see enhanced potassium bubble specificity, namely Asian organizations strengthening mechanisms . Ordered along the filament axis direction of potassium bubble column in processing fibrous form a distinct crystal growth , it is only at very high temperatures to form a clear long fibrous crystals and is very stable, and because of having abnormal , extreme aspect ratio large crystal growth and finger -shaped lock lap crystalline , less grain boundaries , especially grain boundaries transverse (perpendicular to the force of the grain boundaries ) less weakened creep at high temperatures plays a major role in the grain boundary sliding , thereby significantly improved tungsten -doped high-temperature creep strength. Research shows that the larger the aspect ratio , strength increase , the more significant aspect doped tungsten wire , usually above 20 . Experiments also showed that potassium bubbles on dislocation pinning attract and the more general second phase particles more powerful , its processing formed dislocation structure on the high-temperature strengthening greater role .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Potassium-Doped Tungsten Bulbs Strengthen

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:52

Doped tungsten containing potassium atoms due to air bubbles leaving the high-temperature creep resistance tungsten improve mechanisms . In 1918, Americans Perth (A.Pacz) found that tungsten oxide reduction by adding trace amounts of silicon, aluminum , potassium oxide billet prepared by appropriate processing and heat treatment made of tungsten wire has excellent high temperature creep resistance , is ideal incandescent filament material . Doped tungsten is still electronic , electric light source industry is an important basic material . The invention and production of doped tungsten although half a century of history, but due to the testing conditions , people on the micro- doping and Strengthening Mechanisms long failed to recognize , at different times have raised a variety of assumptions and inferences to explain . Therefore, doping and strengthening mechanisms always is a worldwide concern one of the few research topics .

Doped tungsten ordered the formation of potassium -doped tungsten bulb is caused by high-temperature creep resistance excellent basis for this argument is not only fully proved , but gradually made a convincing theoretical explanation , thus forming strengthening and improvement of the potassium bubble theory . Potassium -doped tungsten bulbs and perfect the mechanism of strengthening due to development, has become one of a variety of ways to strengthen the development of new refractory metal materials in the applications.

Potassium reinforcement theory of bubble formation and development can be divided into the following three phases :

( 1 ) Assuming the inference stage . 1957 Si Wolin (R.A.Swalin) and Geissler (A.H.Geisler) proposed a linear arrangement , said dopant , that the doping agent is added during the sintering of tungsten billet maintained during long time the porous state, so that recrystallization grains are fully grown . Reich (G.D.Reich) , who also made a similar linear arrangement dopant , said that the tungsten wire drawing process dopants in a tubular tungsten bronze compounds exist in the form fibers borders , these parallel filaments axis direction is tube-like in the recrystallization process will prevent or inhibit grain growth along the direction of the wire diameter , thereby forming a great aspect ratio of crystal growth . 1962 Milner (T.Miller) dissolving said dopant is proposed that a very small part of the dopant in dissolved form, dissolved particles and the interaction between dislocations , resulting in recrystallization grains grow to form . All these ideas corporations inferences and assumptions , the lack of adequate experimental basis , but to attract people's attention and promote further research has played a positive role.

( 2 ) theory and development phase. In 1967 , the library (R.C.Koo) , who used directly observed by transmission electron microscopy to annealing at a high temperature in the presence of tungsten dopant pressure generated by the vapor formed vesicles period Snow (D.B . Snow) confirmed the vesicles containing potassium atoms. Scholars from various countries were followed by X-ray energy dispersive spectroscopy , secondary ion mass spectroscopy , Auger electron spectroscopy and field ion microscope analysis of the most advanced electronic equipment for various states of doped tungsten microstructure and dopant the morphology and composition of the full system, experiments were observed and the results of each assay , based on the proposed mechanism of doped tungsten strengthen various theoretical explanation . Which the United States Library , Snow and China , who left Tieyong made a more systematic analysis of experimental and theoretical explanations. 1967 to 1985 is potassium -doped tungsten bulbs reinforcement theory with precise experimental basis and the establishment and development period.

( 3 ) potassium bubble theory to the development of new high-strength material phase. Since 1985 , successive refractory metals and hard materials, the International Conference on Theoretical study on the expansion of the bubble potassium and materials to strengthening and toughening materials in the field of basic issues that combine in-depth study of trace impurities on the tungsten, molybdenum grain between adhesion and the electronic structure of grain boundaries , leading to embrittlement microscopic mechanism , and then discusses the harmful effects of eliminating impurities technical measures . In addition , the different regions at different temperatures additive dispersion strengthening and potassium doped tungsten bulbs strengthening mechanisms linking explore refractory material suitable for a variety of strengthening mechanisms combined effects of reinforcement theory . Strengthening and toughening mechanisms for a correct understanding of the design and development of new high-temperature materials provides a theoretical basis .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

the Production Method of Doped Tungsten

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:49

In addition to tungsten powder particle size by reducing temperature , humidity, hydrogen , hydrogen flow rate , the amount of loading the boat , push the boat speed and other factors , the dopants on the grain size is also affected. In general , doped tungsten oxide , to accelerate the reduction rate , the tungsten particles increases. In the tungsten oxide to tungsten powder by hydrogen reduction process, the reaction product should be doped with hydrogen , with the result that the potassium content of the tungsten powder decreased. Pickling tungsten powder is used in the 1960s began to produce , and its main purpose is to wash away excess tungsten powder dopant , ultrafine powder and some of the harmful impurities that can improve the processing performance , improve high temperature properties of tungsten . Production is generally pre-wash first with hydrochloric acid , and then washed with 5% hydrofluoric acid and then repeatedly washed to neutrality , and by low-temperature vacuum drying stage and two-stage reduction reduction reduction systems are different because the resulting tungsten powder particle size are different, the general particle size of the powder than D B fine powder . In actual production , after pickling , B and D pink powder mix to be reasonable , to ensure the match after producing tungsten powder particle size in the 3-4 m range. This is not only to control the average particle size , particle size optimization of composition, and, more importantly, to adjust the potassium content in the tungsten powder . Studies have shown that potassium tungsten particles mainly in the surface 100 within the tungsten powder with the particle size reduction therefore , surface area increases, the potassium content was increased.

However, if the potassium content of tungsten powder is too high, although the filament temperature performance is good, but the resulting processing performance deterioration . Must therefore be based on high temperature properties of tungsten required to determine the potassium content of the tungsten powder and the measured potassium content and particle size to match. Doped tungsten oxide , potassium powder only by the particle size distribution is adjusted , so the production process with powder a very important aspect . Doped tungsten powder pressing and sintering after pressing and sintering , you can get a dense doped tungsten billet . Is the use of force and the mold pressing the loose powder into a certain geometric shape, size , density and strength blanks . Compaction in many ways, the most common is steel cold forming and isostatic pressing ( see isostatic pressing ) . Since the powder between the former and the die and the powder and there is a large friction between the powder and thus the density compacts unevenly distributed within the parts . The latter compacts density distribution is uniform. Actual production , sometimes in order to reduce friction, reduce the pressing pressure , improving the quality of the green compacts . Kept suppressed to a small amount of tungsten powder forming agent or a lubricant ( such as glycerin and alcohol ) . The size of many compacts are generally square or circular cross-section , length 200-l000mm. The powder during the pressing behavior is very complex , which includes powders displacement, deformation or breaking, while it depends on the behavior of the powder particle shape , particle size , particle size and surface composition , these powders suppression characteristics of the tungsten powder process has a very important impact.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Doped Tungsten Doping Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:45

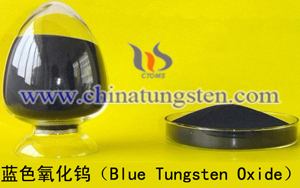

Because blue tungsten oxide powder particles pores and cracks many large surface area , strong adsorption capacity , permeability , chemical activity is good, and in contact with an aqueous solution of a compound having an ion exchange capacity , so the use of blue tungsten oxide doped than doped tungsten oxide doped with better results. Production of tungsten oxide equipment are rotary tube furnace and two kinds. Doped tungsten oxide is tungsten or tungsten oxide doped blue trace hydroxide, alumina. Since the 1960s , many countries have adopted doping process instead of blue tungsten oxide doped tungsten trioxide , thereby increasing the doping effect . In order to make the dopant can be uniformly distributed in the tungsten oxide , the actual production are not used directly , potassium hydroxide, aluminum oxides such insoluble , but with which the decomposition of soluble salts and easy , usually formulated as a potassium silicate and aluminum nitrate ( or aluminum chloride ) was added. Dopant formulations typically within the following ranges ( based on tungsten ) : potassium : 0.3% -0.45 % ; alumina : 0.02% -0.03 % . Doping methods are wet method and the spray French. Wet method in the pot with a steam jacket for evaporation . First, the evaporation pot adding deionized water, was added under constant stirring yellow blue tungsten or tungsten , into a paste, and with stirring , adding potassium silicate solution side , stirred for a while , then add the aluminum nitrate solution , evaporated to dryness moved after drying oven , and finally mixed and sieved .

Spray method is potassium silicate solution was sprayed into the tungsten oxide fine mist ( 80 to 90C) , and continue stirring until basic evaporated to dryness , then a solution of aluminum nitrate was added to the same manner , the final drying , mixing, sieving . Studies have shown that the addition of silicon in the tungsten oxide , potassium aluminum nitrate solution , is not a simple mechanical mixing , but to partially react and generate a multi- tungsten oxide complex tungstate , which generates the same number of characteristics of the substrate , doped miscellaneous agents of the various components and the doping conditions. Tungsten powder and acid preparation is usually used in industrial production hydrogen reduction of tungsten oxide ( blue tungsten oxide or tungsten oxide ) tungsten powder preparation methods . Reduction process, the system depends on the particle size of tungsten powder , particle size composition and oxygen content , potassium content requirements. Often used in a production stage and two-stage reduction to restore two processes . A phase of tungsten oxide reduction is a direct reduction of tungsten powder (D powder ) . Two-stage reduction in two steps : first in the 550-800C will tungsten trioxide or tungsten dioxide reduction of blue tungsten ; Then make tungsten dioxide at 750-900 ℃ reduced to tungsten powder (B powder ) . Reduction is usually in a tubular furnace or rotary furnace . Practice has proved that the particle size of tungsten powder and tungsten trioxide or tungsten blue size is not a simple relationship , with the reduction of different specifications , either coarse or fine tungsten trioxide or blue tungsten powder, tungsten can get crude fine powder or tungsten powder, tungsten powder particle size depends largely on the particle size of tungsten dioxide .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

the R & D Process Doped Tungsten

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:42

Until 1909 , the U.S. General Electric Company Coolidge (wDcoolidge) via powder metallurgy tungsten billet was then produced by machining ductile at room temperature with a tungsten filament , thereby laying the foundation tungsten processing industry , also laid the foundation powder metallurgy . However, this " ductility " tungsten filament in the light bulb lit showed significant brittleness. In 1913, Ping Qi (Pintseh) invented the thorium tungsten wire ( thorium oxide content of 1 % to 2% ) , so that the incandescent filament fragility greatly reduced. Initially, the filament sag ( see tungsten Hang sagging performance ) is not a problem , because the filament is straight wire , but after 1913 , Langmuir (Langmuir) will be replaced by straight wire spiral wire , so that when the light bulb when used , the high operating temperature and weight of the role of the filament sag, thus pure tungsten and tungsten are difficult to meet community requirements . In order to solve tungsten droop and short life and other issues, in 1917 , Perth (A.Pacz) invented the high temperatures , " no deformation " of the tungsten filament . At first, he used when in the preparation of pure tungsten Woe roasting fire tower tungsten trioxide , stumbled with this reduction of tungsten trioxide proceeds made from tungsten powder tungsten spiral , after recrystallization exception mysteriously no longer droop.

Then, after 218 repeated experiments , he finally found that adding potassium tungstate and sodium silicate , after reduction , pressing, sintering and processing the obtained tungsten wire , a fairly coarse recrystallized grain structure neither soft and anti- sagging, this is the earliest non- sag tungsten wire . Perth discoveries laid the basis for the production of non- sag tungsten , until now, the United States does not sag tungsten wire is still called " 218 tungsten wire " to commemorate this major discovery in Perth . However, the first production does not sag tungsten filament brittle than male serious that some insist on using Vitex tungsten bulb factory for the filament. But with no sag tungsten production process of continuous development and improvement , people gradually realized by simultaneously adding the potassium tungsten oxide , silicon, aluminum compounds , can make the tungsten filament at high temperatures with a good anti- sag performance, but by then after crystallization has satisfactory ductility at room temperature . This is now commonly known as "AKS tungsten wire ," or " does not sag tungsten wire " or " doped tungsten wire ." It has many excellent properties , and become the electric light and electronic industries as an important base material . A brief history of the development of tungsten industry from the outset with the light bulb industry closely linked . In 1878 , Edison (TA Edison) invented the carbon filament light bulbs. But this lamp there is a serious disadvantage , primarily life is too short .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Doped Tungsten Production Processes

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 14:39

Carolina (T.Millner) in 1931 will this improvement does not sag effect is known as "GK effect ." Then mixed tungsten -doped tungsten production process lengthy production processes , including tungsten smelting, processing of powder metallurgy and plastic preform several major phases . Preparation of tungsten billet billet production of tungsten used usually prepared by powder metallurgy , which includes the preparation of tungsten oxide , doped tungsten powder preparation , pickling, and pressure- sintering process . Preparation of tungsten oxide doped tungsten production is usually chosen by Jones Lang tungstate (APT) as raw materials . Preparation paratungstic from tungsten acid Holderness addition to traditional classical technique , but in the 1950s the international community to carry out extraction and ion exchange method of research, China in the 1970s also used these processes , thereby simplifying the process, improved recovery of tungsten . Industrial preparation of tungsten oxide in two ways :

(1) At a temperature of 500 to 800 ℃ calcined paratungstic acid obtained by the yellow tungsten trioxide ;

( 2 ) Temperature at 400 to 600C in a reducing gas atmosphere at reduced paratungstic acid blue tungsten oxide .

Blue tungsten oxide there is no fixed formula and uniform chemical composition , the main phases money tungsten bronze (ATB) and tungsten oxide . Followed tungsten trioxide , in a reducing atmosphere at a higher temperature will appear in the carbon filament yarn and buttons are spades replaced wire , but thallium low melting point, and thus the operating temperature and luminous efficiency is low . 1903 , according to Jay zafirlukast (A.Just) and Hannah door (F.Hannaman) patents, Hungary for the first time to create a tungsten filament. It is the carbon filament of hydrogen containing tungsten oxyhalide steam heated to high temperatures by the current , the carbon was completely replaced tungsten . Incandescent filament thus obtained contain more or less of carbon , not brittle quite serious , and in the use of the lamp , the filament continued densification , and thus the electrical parameters of the filament will change . In 1904, Jay zafirlukast and Hanna door recognizes the impact of carbon on the brittleness , using carbon- tungsten compound is mixed with a binder , and then extruded into filaments , and then heated in hydrogen reduced to metal . This method is very brittle tungsten obtained , but because of its much better light efficiency , or replacing the carbon filament , hungry for the production of filaments and filament lamps bear . These methods are not prepared thin tungsten wire. To solve this problem , in 1907 , a low nickel content of the tungsten alloy available, it is prepared by machining , but serious brittleness hindered its application .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Detect A Fake Tungsten Gold Bar

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 October 2013 13:48

Detecting a high-quality fake tungsten gold bar would be extremely difficult. It would likely require significant and material alterations to the bar being tested and this would negatively affect the marketability if its hallmark veracity were vindicated.

This is likely a reason why page Page 11 of the GLD prospectus states “Neither the Trustee nor the Custodian independently confirms the fineness of the gold allocated to the Trust in connection with the creation of a Basket.”

Nevertheless, the truly determined and experienced can ferret out whether there is tungsten contained in their gold bars. In fact, some already have found tungsten in bars which purport to be gold and this is how.

Gold plated Tungsten Product Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com