What Is Tungsten Alloy Shielding Component?

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2025 13:56

With the rapid development of industries such as nuclear energy, medical imaging, and industrial inspection, the demand for efficient and environmentally friendly shielding materials is increasingly urgent. Tungsten alloy shielding components, as high-performance radiation protection elements, are gradually replacing traditional lead-based materials due to their exceptional shielding efficiency, mechanical strength, and eco-friendly properties, becoming the preferred solution in radiation protection. For tungsten alloy shielding components, please contact CTIA GROUP LTD Online: sales@chinatungsten.com, 0592-5129595.

Applications of Tungsten Alloy Counterweights

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2025 13:53

CTIA GROUP LTD tungsten alloy counterweights are renowned for their high density, excellent mechanical properties, corrosion resistance, and processing flexibility.

CTIA GROUP Tungsten Alloy Rehabilitation & Fitness Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 October 2025 16:58

CTIA GROUP Tungsten Alloy Rehabilitation & Fitness Balls — Technological Metal, Embodying the Beauty of Strength, Health & Balance

I. CTIA’s Tungsten Alloy Rehabilitation & Fitness Balls

What Is Tungsten Alloy Weights?

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2025 14:10

In modern technology and industrial fields, high-precision weight measurement is a critical factor in ensuring quality and driving innovation. From microscopic chemical analysis in laboratories to quality inspections on industrial production lines, accurate weight data serves as the foundation for scientific discoveries and production efficiency. In these high-precision scenarios, tungsten alloy weights stand out as essential measurement tools due to their exceptional performance and stability.

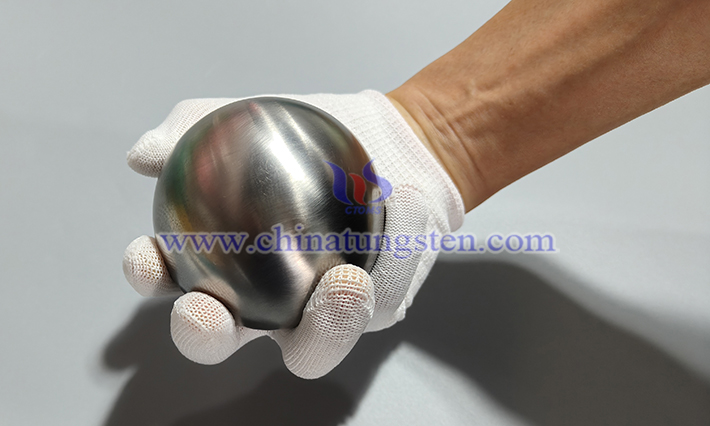

What Is Tungsten Alloy Fitness Ball?

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2025 14:07

The CTIA GROUP LTD Tungsten alloy fitness ball is a fitness device made from high-density tungsten alloy material, designed in a spherical shape, primarily used for hand strength training, grip exercises, stress relief, and functional fitness. This fitness ball combines the portability of traditional fitness balls with the high density and strength of tungsten alloy, making it suitable for fitness enthusiasts, athletes, and specific groups needing enhanced hand strength who seek efficient and precise training.

Characteristics of Tungsten Alloy Fitness Balls

- Details

- Category: Tungsten Information

- Published on Monday, 20 October 2025 14:03

CTIA GROUP LTD tungsten alloy fitness balls are small fitness devices made from tungsten alloy materials, with core features including high density and small volume. Under the same weight, their size is significantly smaller than traditional steel or stone balls. These characteristics provide unique advantages in fitness, rehabilitation, and stress management, while their durability and portability further expand their application scenarios. Whether for professional athletes or casual fitness enthusiasts, tungsten alloy fitness balls offer an efficient and durable training experience.

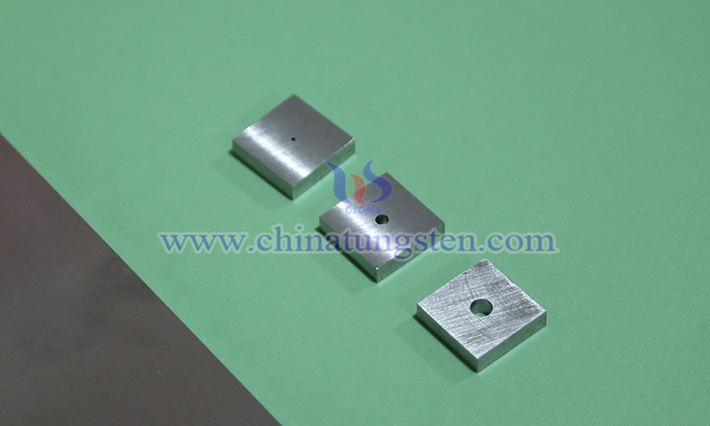

Characteristics of Tungsten Alloy Weights

- Details

- Category: Tungsten Information

- Published on Thursday, 16 October 2025 18:44

Tungsten alloy weights, made primarily from tungsten with the addition of metals such as nickel and copper, are high-density metrology instruments and key tools in the field of mass measurement. They are used to calibrate electronic balances, platform scales, and other balances, and serve as standard components in laboratories and industrial quality inspections. Tungsten alloy weights exhibit the following key characteristics:

What Is Tungsten Alloy Weights?

- Details

- Category: Tungsten Information

- Published on Thursday, 16 October 2025 18:42

Tungsten alloy weights, made primarily from tungsten combined with other metal elements such as nickel and copper, are precision counterweights or measuring tools widely used in metrology and calibration fields.

Tungsten Carbide Balls for Precision Instruments

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 20:22

With their high hardness, wear resistance, and precision characteristics, tungsten carbide balls are indispensable components in precision instruments. Advances in their manufacturing processes and expanding application areas will further drive the development of related industries.

Tungsten Carbide Balls for Valve Sealing

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 October 2025 20:18

With their exceptional physical and chemical properties, tungsten carbide balls are extensively utilized in various valve sealing systems, providing essential support for efficient and safe operation.

sales@chinatungsten.com

sales@chinatungsten.com