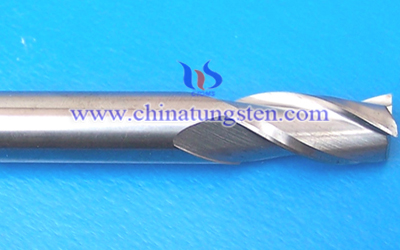

Tungsten Carbide High Speed End Mills Structural Features

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 18:12

- Written by limei

- Hits: 480

Tungsten carbide cutting tools structure is an important factor in the decision to performance of tungsten carbide cutting tools.Tool manufacturers at home and abroad attached great importance to tungsten carbide tools structure research and development.

Tungsten carbide high speed end mills structural features have two main aspects. On the one hand, tungsten carbide high speed end mills are mainly whole and tipped categories. Due to centrifugal force and high-speed machining shake, structural safety and balance of tungsten carbide high speed end mills are essential. Tungsten carbide high speed end mills system must have good balance and security.Tungsten carbide high speed end mills structural features on the other hand lies in that tipped categories usually use tool machine folder structure, Centrifugal force which will cause carbide blade and blade intensify structural damage and broken blade or get rid of, so the knife body and clamping mechanism must have high strength and fracture toughness and rigidity to ensure safe and reliable.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Powder Extrusion Molding Strategy

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 18:00

- Written by Cristina

- Hits: 440

Tungsten Carbide Rod Powder Extrusion Molding Strategy

Although tungsten carbide rod powder extrusion molding has improved a lot in recent years, there are also many problems like immaturity in the research of knowledge and technology. Especially the research of rheology extrusion has a great distance with other countries. The only thing we can do is to keep doing research in order to catch up with or even surpass advanced world levels. The following are some strategy for the existing problems:

1.Actively develop the technical research in rheology extrusion. Organize the research group; mirror other rheology method like industrial rheology and basic rheology to study the extrudate performance and basic rheological behavior so that we can apply rheology parameter in the research of extrusion molding.

2.Vigorously develop the extrusion binder. In the present we have no resources from other countries and there is no access to get information from the report. So we can only do the research by ourselves and make cooperation with chemical engineering, produce practical binder which can fit in various types of tungsten carbide powder.

3.Develop the research in the synchronization of tungsten carbide rod powder extrusion molding and equipment. Figure out the influence of rheology extrusion under different feedstock on the density of the tungsten carbide rod and extrusion method.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Molding Process

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:55

- Written by Cristina

- Hits: 437

Tungsten Carbide Rod Molding Process

Tungsten carbide rod molding process can be divided into two methods which are horizontal direction and vertical direction.

Horizontal direction:

Firstly, shape the two punches of the mold into a round-rod shape and press out powder between them. Under this process, the length of rods would be easily restricted by the specifications of the mold and pressing machines. Due to the uneven pressure from both punches, there can be gaps formed in the blank voids, and they are difficult to close. There are some possibilities that the cobalt contents is increasing and thus creates the so-called cracking which can not be fixed.

Vertical direction:

Similar to the horizontal repression process, the specifications and length of the rods are also being restricted by the specifications of the mold and pressing machines and cannot be easily extruded out in the vertical direction.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Powder Metallurgy History

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:58

- Written by Cristina

- Hits: 442

Tungsten Carbide Rod Powder Metallurgy History

The history of tungsten carbide rod powder metallurgy and the art of metal and ceramic sintering are intimately related to each other. Sintering involves the production of a hard solid metal or ceramic piece from a starting powder. "While a crude form of iron powder metallurgy existed in Egypt as early as 3000 B.C, the smiths of India produced the famous "Iron pillar of Delhi", weighing about 6.5 tons, and other objects even larger as early as 300 A.D, and the ancient Incas made jewelry and other artifacts from precious metal powders, mass manufacturing of P/M products did not begin until the mid- or late- 19th century.

The invention of tungsten filament lamp impels the development of powder metallurgy. In 1932, tungsten carbide rod powder metallurgy marks a great improvement in powder metallurgy. Tungsten carbide rod powder metallurgy overcomes the casting problems of the refractor metal.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rod Isostatic Pressing

- Details

- Category: Tungsten Information

- Published on Monday, 01 June 2015 17:48

- Written by Cristina

- Hits: 501

Tungsten Carbide Rod Isostatic Pressing

Tungsten carbide rod isostatic pressing is a mass-conserving shaping process. Fine metal particles are placed into a flexible mould and then high gas or fluid pressure is applied to the mould. The resulting article is then sintered in a furnace which increases the strength of the part by bonding the metal particles. This manufacturing process can be used to make many different shapes. Tungsten carbide rod isostatic pressing can be divided into hot isostatic pressing and cold isostatic pressing.

Hot isostatic pressing (HIP) compresses and sinters the part simultaneously by applying heat ranging from 900 °F (480 °C) to 2250 °F (1230 °C). Argon gas is the most common gas used in HIP because it is an inert gas, thus prevents chemical reactions during the operation.

Cold isostatic pressing (CIP) uses fluid as a means of applying pressure to the mold at room temperature. After removal the part still needs to be sintered. It is the process by which fluid medium especially liquid is preferred as a working medium. It is helpful in distributing pressure uniformly over the compaction material contained in a rubber bag.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com