Tungsten Carbide Woodcutting Tool Cutting Edge Wear Forms

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2015 14:31

- Written by lucy

- Hits: 410

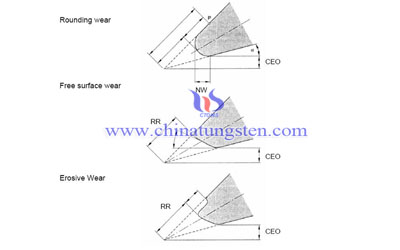

Generally ,there are three typical cutting edge wear forms of a tungsten carbide woodcutting tool regarded to its working environment and tool life, which may occur simultaneously. The three types could be cataloged as rounding wear, free surface wear and erosive wear.

Depending on geometric descriptions of the worn, the tool nose rounding could be examined. Rounding wear defines the rounding off of the cutting edge so that it has a constant radius. Free surface wear defines a combination of rounding wear and in addition flattening of the edge occurs. Erosive wear occurs in the area close to the cutting edge. There are many ways in which to describe the changing wear profile , simply the three dimensional descriptions are listed as, the edge recession from the original edge parallel to the rake face(RR), the cutting edge offset(CEO) and the nose width(NW).

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Target Properties

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2015 14:27

- Written by Yahong

- Hits: 452

Tungsten target namely tungsten sputtering target,which owns high melting point, elasticity, low coefficient of thermal expansion, resistivity and fine heat stability and other properties.

Tungsten target is made from tungsten powder by spraying tungsten powder, sintering and other production processes. Tungsten target properties:

Density:≥99%;

Average grain diameter of transparent:≥100um;

Oxygen-containing:≤20ppm;

Wrestling deflection characteristic is about 500Mpa;

By increasing raw metal powder production, improving the sintering ability to make tungsten target costs stabilized at a low price and have quality assurance. Conventional pressing and sintering methods can not achieve a high level of transparency framework of new sintering and can’t improve the resulting deflection wrestling, so that a significant reduction in particulate matter occurs.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Sputtering Target

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2015 14:25

- Written by Yahong

- Hits: 430

Tungsten sputtering target is made of tungsten powder. Tungsten sputtering target owns three types: flat-target type, arc-target type and rotary target type.

Because target quality will directly affect film performance, so the tungsten sputtering targets must meet the following requirements:

High purity; the higher purity of the tungsten sputtering target, the better effect of spray sputtered film and electrical and optical properties, and the stronger of corrosion resistance. In general, semiconductor devices and monitors purity of tungsten sputtering target have more stringent requirements, for example, a magnetic thin film of tungsten target purity requirements is generally above 99.9%.

High density;

Small grain size;

Low impurity content; tungsten sputtering target, as a cathode, its main sources of pollution is from the pores of oxygen in the water and solid impurities. We can obtain the higher purity of tungsten sputtering target by lowering the impurity content.

Even composition and homogeneous structure are required.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Woodcutting Tool Cutting Edge Profiles (2)

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2015 14:27

- Written by lucy

- Hits: 410

It is known that the cutting edge changes during use, which leads to changes of the strength and wear resistance of the tool and the force system with time. Therefore re-shapern and change should be taken place, when cutting edges reach a critical condition. Given the various tungsten carbide woodcutting tool combinations, the critical conditions need to be assessed for each combination separately. Cleaning the tools at regular intervals limits wear. Uncleaned knives lead to bad quality in wood products, shortens the cutting length and increases the cutting forces. Dirt particles can also act as abrasive wear particles during further cutting.

Frequently cutting edges do not wear evenly and due to a local wear ‘difference’ have to be changed even though they are still operational. The amount of edge recession was found to vary with board density variation, giving a jagged profile.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Inserts’ Wear Mechanisms in Green Oak Machining

- Details

- Category: Tungsten Information

- Published on Friday, 29 May 2015 14:17

- Written by lucy

- Hits: 430

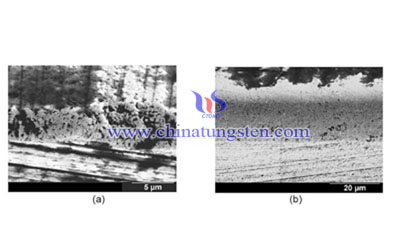

When using tungsten carbide inserts in green oak machining, some typical degradation would be identified by examining its wear mechanisms.

There is no attack occurred between tungsten carbide grains and the extractives when the cobalt binder is removed from the interstices. Some researchers suggested that the depth of the cobalt binder is removed, is of the order of the tungsten carbide grain size at any stage in the life of a tool. It also suggested that wear occurs primarily by preferential dissolution of the binder phase though chemical attack by the extractives present in the Oak which is then followed by loss of individual carbide grains when the strength of the remaining WC-Co-bond is insufficient to resist action of the shear forces caused by motion of chip and wood over the tool face. This motion would, in addition, be responsible for removing any corrosion reaction products which may form during cutting. Such a mechanism is fundamentally different to that which usually occurs in metal cutting.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com