Tungsten alloy rod rotary forging machine swaging

- Details

- Category: Tungsten Information

- Published on Thursday, 08 May 2014 11:43

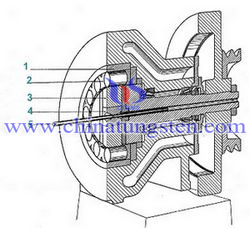

Tungsten alloy rod rotary forging swaging machine is a device, which can be reduced by a mold design tungsten alloy rod diameter mold is designed to about 10,000 per minute impact hammer stick.

Generally, a swager will reduce the diameter of rod about 12% per pass. Swaging elongates the crystals, creating a fibrous structure. Although this is desirable in the finished product for ductility and strength, at this point the tungsten alloy rod must be stress-relieved by reheating.

We provide high quality tungsten alloy swaging rod and Specific lengths and special fabrications can be supplied upon request.

Picture above shows the regular structure of swager for tungsten alloy rod :

1. Hardened Steel Liner

2. Roller Cage

3. Backers

4. Hammers

5. Tungsten Alloy Rod

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Swaging Rod

- Details

- Category: Tungsten Information

- Published on Thursday, 08 May 2014 10:56

The tungsten alloy can be produced in a variety of near-final shapes, but the most frequently encountered shape is that of cylindrical rods, which may be subjected to a series of thermo-mechanical treatments to improve their mechanical properties. For example, tungsten alloy rods are frequently swaged to improve their strength,which results in tungsten alloy swaging rod.

Tungsten alloy swaging rod is made from tungsten alloy rod through swaging which greatly enhance its tensile strength from 1050 MPa to 1200 MPa at least.

Tungsten alloy swaging rod is produced by pressing and sintering tungsten alloy rod into billets, swaging into rod. Smaller sizes of tungsten alloy swaging rod are produced by subsequent drawing. The diameters of tungsten alloy rod through swaging will at 3mm or larger, while if tungsten alloy swaging rod through drawing process, the diameter of it will be below diameters 3mm.

Why Use Tungsten Alloy

Titanium is also popular used materials for producing swaging rod. Titanium's physical qualities of high strength, toughness, durability, corrosion resistance and biological compatibility make it useful in making swaging rod. While titanium's density is much lower which make it difficult in the situation that needing high mass with limited volume.

Tungsten alloy with high density, high melting point, excellent hardness, high tensile strength, high temperature resistance and low vapor pressure is gradually standout among the various swaging rod making materials. What is more, tungsten alloy has superior wearing resistance, prolongs the life of tungsten alloy swaging rod.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Drill Welding Technology Demonstration

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:49

Tungsten carbide drill welding technology demonstration.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

VX-OT Tungsten Carbide Taps

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:43

VX-OT tungsten carbide taps can be processed more than HRC50 material.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Saw Blade Automatic Welding

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:42

Tungsten carbide saw blade automatic welding display.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tile Cutter Knife Round

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:40

Tungsten carbide tile cutter wheel used mainly YG6 carbide grades, hardness up to 91-degree cut mainly for floor tiles.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Milling Inserts

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:37

Tungsten carbide milling inserts a major role in steel, alloy steel, stainless steel, cast iron, aluminum alloy surface milling.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungstern Carbide Die Flayer

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:35

Tungsten carbide die flayer oxide layer is mainly used to strip the metal surface of copper, aluminum, steel, etc., dirty layer or other coating.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

American BEST CARBIDE Tungsten Carbide Steel Cutter

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:33

American BEST CARBIDE tungsten carbide steel cutter show video.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Non-Standard Tungsten Carbide Coated End Mills

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2014 09:31

Non-standard carbide coated end mills show.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com