Tungsten Ore Processing Production line--Ball Mill

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 11:00

Tungsten Ore processing production line--ball mill Introduction:

Tungsten Ore processing production line --ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrous&non-ferrous metal mine, building materials, chemical, electric power, coal, traffic, light industry, etc. In our company, this series of high-efficiency ball mill adopts rolling bearing support instead of sliding bearing support with bearing bush. Therefore, it can save energy by 10-20%. According to different discharging ways, it can be divided into two kinds, grate type and overflow type.

Structural characteristics of Tungsten Ore processing production line--ball mill:

Tungsten Ore processing production line --ball mill is made up of feeder part ,discharging part ,rotating part ,transmission part(reducer,samll transmission gear ,motor,electric control) etc. main part.Hollow shaft adopt steel casting, lining can be converted,big rotating gear processed by casting gear hobbing .In the barrel there are board of wear-resistant,have a good characteriatics of wear-resisting.The machine is of steady operating and reliable working.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Free Alkali Recovery From NaOH Leaching Liquor of Tungsten Ore by Electrolysis with Ion-Exchange Membrane

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 10:57

Caustic soda leaching liquor of tungsten ore always contains a certain amount of free alkali. General method of removing free alkali in the liquor is to neutralize it by inorganic acid. A new method, i.e. applying electrolysis with ion-exchange membrane to recover free alkali from caustic soda leaching liquor of tungsten ore, was proposed in the paper. In the electrolysis cell the effective area of membrane is 100 mm×100 mm, the anode is β PbO2 plated at screen of titanium net, the cathode is active nickel plated at screen of stainless steel net, and the membrane is a kind of perfluorsulphonic acid membrane. Some effect factors of electrolysis process including the NaOH concentration in anolyte and catholyte, distance between electrodes, temperature, current density, are investigated. The results show that, by choosing proper operating condition, the specific energy consumption can be controlled within 2 kWh•kg-1NaOH. Electrolysis with ion-exchange membrane can not only recover free alkali from caustic soda leaching liquor, reduce the consumption of inorganic acid, but also utilize the hydrogen gas produced in the process to produce tungsten powder.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Beneficiation Process of Tungsten Ore-II

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 10:25

Tungsten smelting and fire refining method are two kinds of water law. The use of wolframite concentrate or smelting scheelite concentrate, but different smelting process, so both wolframite deposits, there scheelite, we must each ore body, each calculated reserves. When the ore wolframite, scheelite coexists together, to elect a black tungsten concentrate and scheelite concentrate for smelting, respectively. The smelting of mineral raw materials as tungsten tungsten ore concentrates, containing WO3 should meet or greater than 65%. The pyrometallurgical into tungsten alloy (with W>70 or>65%) by Water Act, a positive tungsten smelting sodium, calcium APT or tungsten, etc. Finally, further processed into tungsten trioxide (containing WO3>=99.9%), then reducing agent (usually hydrogen) is reduced to tungsten powder (with W>=99.9%) and so on.

Tungsten is recovered from scheelite ore concentrates, or other tungsten concentrates which may, or may not contain scheelite in the form of sodium tungstate and in yields up to 99.5 percent or more by a process in which ground ore substantially below 200 mesh in particle size is first added to a 50 percent sodium hydroxide solution while being agitated to such an extent that the resulting mixture becomes a semi-solid as the temperature is raised above 80C. The semi-solid is then baked at 135 to 145C for about 1 to 2 hours, followed by adding sufficient water to the semi-solid to form a slurry having a sodium hydroxide concentration below 6 molar, separating the causticinsoluble sludge from the slurry and washing the sludge with a dilute sodium hydroxide solution to remove residual sodium tungstate.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Beneficiation Process of Tungsten Ore-I

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 10:06

Tungsten ore low must be integrated mineral-rich concentrate to a smelting raw material. According to the type of tungsten ore dressing it can be divided into wolframite and scheelite mineral beneficiation two types. Present mining to wolframite quartz vein type, accounting for the amount of ore taken out more than 90%. Tungsten ore dressing methods mainly include hand-selected, HM election, re-election, flotation, magnetic separation and electrostatic separation methods such as. Wolframite in order to re-election dominated by flotation mainly scheelite. Most of our wolframite is easy to choose the type of ore, while the composition of scheelite ore complex, and mostly of refractory ore, coupled with low grade, so not a lot of development.

In addition, tungsten oxide minerals such as tungsten China currently not recycled. China's tungsten ore dressing and processing plant started in 1952 a large-scale factory in Dajishan Tungsten establish 125t / d of gravity concentration plant, the late 50s, former Soviet Union Mechanobr Research and Design Institute for the downhill , West Mountain and hilly Miyama tungsten designed three large-scale tungsten ore processing plant put into operation one after another. 40 years in the production practice constantly sum up experience, and absorb foreign advanced technology dressing, through continuous improvement, so that beneficiation process is improving daily, processing technical and economic indicators have reached the world advanced level. Nanchang representative non-ferrous metals such as tungsten ore beneficiation company targets, despite nearly 10 years in the annual decline in ore grade, the tungsten recovery remained at 84% or more of the high concentrate grade (WO3) 66.7 % ~ 68.9% (up to 12 tungsten national standards: WO3 content is not less than 65%), ore grade (WO3) 0.25% ~ 0.27%, tailing grade (WO3) 0.036% ~ 0.046%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

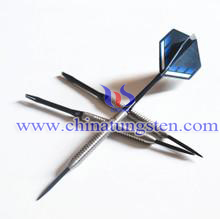

Baseball Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 18:35

Number of Players: Any number can play, but it is unusual to have only two players or two teams (like the game of baseball itself)

Numbers in Play: 1, 2, 3, 4, 5, 6 , 7, 8, 9

Rules of Play: This game is similar to the actual game of baseball. Players try to score as many points as possible per inning in order to win. The goal is to hit the number that corresponds to the current inning. For example, in the first inning players can only hit a 1 in order to score points. For any inning, a single is one run, a double is two runs, and a triple is three.

At the end of nine innings, the player with the most runs wins. If the players are tied at the end of nine innings, extra innings can be played with an equal number of turns per player (just like real baseball) until someone wins.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Adding Elements to Improve Tungsten Carbide Button

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 17:59

As we know, some manufactory would add a little TaC, which can improve alloy binder component for enhancing the wear resistance, toughness and strength. While it means that more cost and if add excessively, the results would reverse. After the addition of Ni, P in WC-Co cemented carbide can be formed Ni-Co-P, Ni-P and Co-P. The eutectic temperature of Co-P is 1020 degrees, the eutectic temperature of Ni-P is 880 degrees, and Co 1340 degrees lower than the melting point of 1495 degrees and WC-Co's. The main reason is that P atomic adsorption and segregation in Ni, Co particle surface, thereby reducing the energy of surface of Ni, Co particles. Therefore, such alloys in the liquid phase, and it makes early appearance dissolution and precipitation and the formation of the skeleton of solid particles also occurred in advance to make the process more fully sintered at a relatively low temperature. So it can effectively accelerate the speed of hard densification and improve the performance of tungsten carbide button.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Low-Temperature Molten Salt Method to Produce Tungsten Cobalt

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 17:56

Using low-temperature molten salt method to produce tungsten cobalt and the producing processes are as follow:

1. In accordance with the mass ratio of 1.17: 1 obtain LiNO3-Na2WO4 mixed molten salt.

2. The Co and W at quantity relative ratio of 1: 1, respectively formulated into aqueous solubility is 1mol/L and then under vigorous stirring, the solution was slowly dropped into Na2WO4 and CoCl2 solution with stirred 30min so that the two solutions were thoroughly mixed.

3. The mixture was filtered, precipitate and washed, dried at 80 ℃ in the oven to give the precursor of CoWO4.

4. to weighed molten salt and precursor by mass ratio of 6: 1 in the mortar mix evenly put it into alumina clamp pot, the pot will be placed in the electric furnace holding 8h at 210,270,340 ℃.

5. After the synthesis reaction was allowed to cool to room temperature, to obtain a solid product, which was after distillation, washing, filtration and drying to obtain the final powder sample.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Optimization Profile

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 17:56

With the development of deep drilling and oilfield excavation, the performance of tungsten carbide button is also concerned. Most of profiles of tungsten carbide button are ball-shaped, and bullet-shaped. But it would be easily deactivate when we use the ball-shaped and the bullet-shaped would be vulnerable because of lackness of the matrix under a large impact. Based on the effective mechanism of spherical broken rock and bending stress curve theory, some researchers design blunt-resistant tungsten carbide button. It combines the advantages of the ball-shaped with the bullet-shaped, which is composed of two parts, a spherical cap and a cone. Spherical side is used in ball-shaped pressing die, and another approximate cone side is used in wedge pressing so that the effect of rock breaking is improved.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Crystallization of Ultra-fine Tungsten Carbide Button

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 17:53

With the requirement of rock drilling higher and higher, which means that it should has good toughness against impact and high abrasive resistance. And the use of crystallization of ultra-fine structure can obviously improve the performance of tungsten carbide ball button. There is research data shows that carbide binder phase content unchanged, while WC grain size of less than 1μm, alloy hardness and strength of will get obviously improved. What’s more, with the size of WC grain reduced further, the promotion will be more visible.

As the particle has small size, large surface area, and surface strong reactivity, which makes it certain specific properties will be able to simultaneously increase the strength and hardness of tungsten carbide button. Therefore, many of the scholars or researchers study set the goals and directions on the refinement of carbide grains to nanometer so that both of hardness and strength can be enhanced. It can extend the working life of tungsten carbide button and decrease the cost of production.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Cobalt

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 17:53

Tungsten cobalt chemical formula is CoWO4 and molecular weight is 307.78. It has wolframite structure, CAS number: 12640-47-0. Tungsten cobalt as a functional material widely used in anti-knock, paint additives, catalysts, microwave dielectric ceramics and optical anode materials.

There are many methods for producing CoWO4 which are traditional solid-phase method and wet chemical methods including co-precipitation method, hydrothermal method, spray pyrolysis method and so on. However, these method more or less are some problems, such as conventional solid-phase method need high synthesis temperature, larger energy consumption, the resulting powder particle size is large, irregular shape. While co-precipitation method can effectively realize the reaction components are homogeneously mixed at the atomic scale, but get precipitate requires high temperatures calcination process. Besides, the hydrothermal method more strict on equipment and has complex operation. After a series of studies found that low-temperature molten salt method produce tungsten cobalt not only process simple, and do not ask more of technical equipment, it is conducive to large-scale production.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com