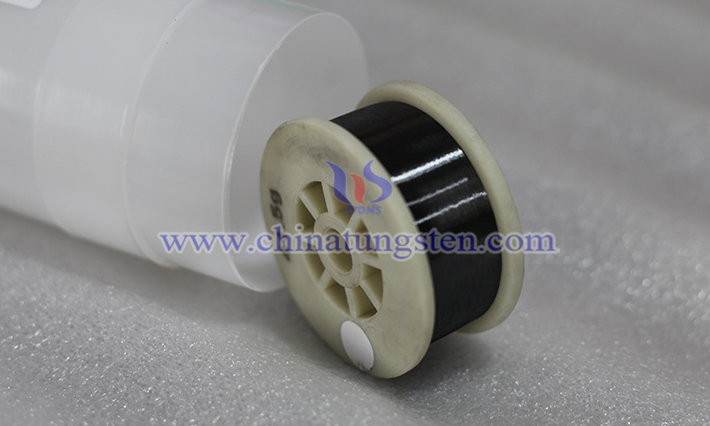

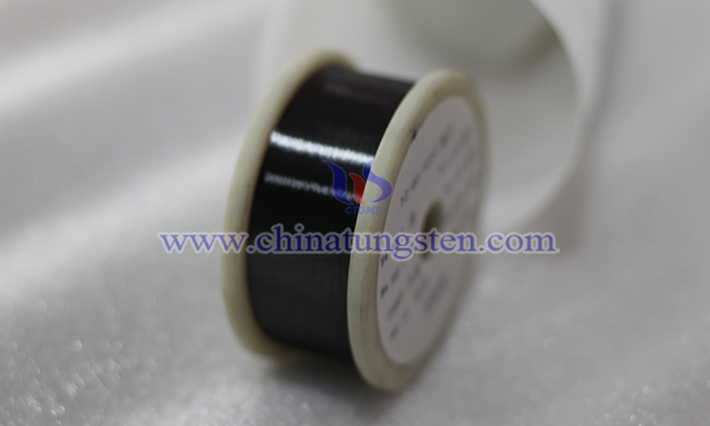

Tungsten Wire Tensile Strength and Ductility

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 16:36

The tensile strength and ductility of tungsten wire complement each other. Its high strength ensures structural stability, while its moderate ductility enables it to be processed into complex shapes. Tungsten wire's ultra-high tensile strength and controllable ductility make it widely used in lighting, electronics, aerospace, and other fields.

1. Tensile Strength

Tungsten wire's extremely high tensile strength is one of its key properties as a high-temperature and structural material. The tensile strength of pure tungsten is typically between 800 and 1000 MPa at room temperature. Through doping (such as potassium, aluminum, and silicon) or processing optimization (such as wire drawing and heat treatment), its tensile strength can be significantly increased, reaching as high as 2000-3000 MPa. Tungsten's high strength stems from its body-centered cubic crystal structure and strong metallic bonds, which enable it to maintain excellent mechanical properties even at high temperatures. For example, in incandescent lamps, tungsten wires can withstand significant mechanical stress at temperatures of approximately 2500°C without breaking. This property makes tungsten wire an irreplaceable material for high-temperature filaments, cathodes in electronic devices, and in aerospace applications.

Tensile strength is closely related to the microstructure of tungsten wires. During the drawing process, tungsten wires develop a fine, fibrous grain structure, which significantly increases their strength but may also introduce internal stresses. Annealing can partially eliminate these internal stresses, further optimizing the balance between strength and toughness. Furthermore, while the tensile strength of tungsten wire decreases with increasing temperature, it remains far superior to most metals below 1000°C, demonstrating its reliability in extreme environments.

2. Ductility

Although tungsten exhibits relatively poor ductility at room temperature (appearing to be brittle), it can exhibit excellent ductility through appropriate processing. This ductility is fundamental to tungsten wire's ability to be drawn into extremely fine wires (e.g., less than 0.01 mm in diameter), thanks to its ability to plastically deform at high temperatures. During the wire drawing process, the tungsten blank is heated to 1000-1500°C to reduce its brittleness and improve its ductility. Doping tungsten wire (such as potassium-doped tungsten wire) further improves ductility by forming fine bubbles and strengthening grain boundaries, making it less susceptible to intergranular fracture at high temperatures.

The ductility of tungsten wire is also closely related to its purity and processing technology. High-purity tungsten wire has poor ductility at low temperatures, but its plasticity can be significantly improved by controlling impurity content (such as oxygen and nitrogen) and optimizing the wire drawing process. Furthermore, tungsten wire's ductility improves at high temperatures, making it suitable for applications requiring repeated bending or forming, such as coiled filaments in vacuum devices.

In practical applications, the performance of tungsten wire requires a balance between strength and ductility through optimization of doping, heat treatment, and wire drawing processes. For example, the long service life of potassium-doped tungsten wire in incandescent lamps is due to its high strength and good ductility to withstand thermal cycling stress. However, the brittleness of tungsten wire at low temperatures remains a challenge and needs to be further improved through alloying or surface treatment.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com