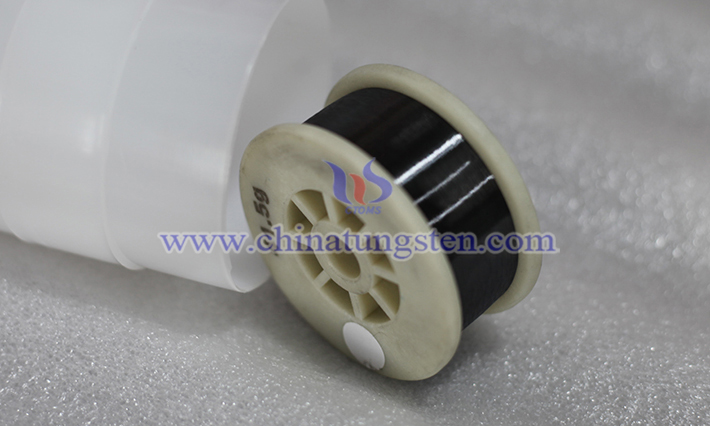

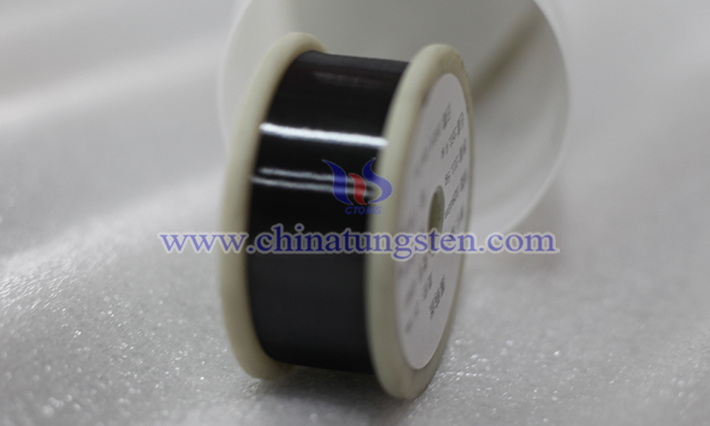

Black Tungsten Wire Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 18:44

Due to its high melting point, corrosion resistance, and excellent electrical conductivity, black tungsten wire is widely used in lighting, electronic devices, and high-temperature equipment. Its manufacturing process is complex and precise, involving multiple steps. The main processes are briefly described below.

1. Tungsten Ore Extraction

The production of black tungsten wire begins with the extraction of tungsten ore (such as wolframite or scheelite). After crushing and grinding, the tungsten ore is separated into tungsten concentrate through flotation or gravity separation. The concentrate is then converted into ammonium paratungstate (APT) through chemical methods (such as acid leaching or alkaline leaching). APT is then calcined to produce tungsten trioxide (WO₃), providing high-purity raw material for subsequent processes.

2. Tungsten Powder Preparation

Tungsten trioxide is reduced to metallic tungsten powder in a high-temperature reduction furnace under a hydrogen atmosphere. The reduction process requires precise control of temperature, hydrogen flow, and duration to ensure uniform tungsten powder particles and high purity. The particle size distribution of tungsten powder directly impacts the performance of subsequent forming processes.

3. Pressing and Sintering

Tungsten powder is pressed into tungsten bars through a die. The pressed bars are sintered in a high-temperature sintering furnace under a hydrogen atmosphere to prevent oxidation. The sintering process bonds the tungsten particles, forming a dense tungsten billet with sufficient mechanical strength.

4. Forging and Wire Drawing

The sintered tungsten billet is forged at high temperature in a rotary forge to increase its density and toughness. The billet is then drawn multiple times into fine wire. The wire drawing process is carried out at high temperatures, using diamond dies to gradually reduce the diameter until the target specification is reached. To prevent oxidation, wire drawing is often performed in an inert gas or vacuum environment.

5. Cutting and Forming

Tungsten wire can be cut, coiled, or straightened to meet specific requirements. Some black tungsten wires require annealing to eliminate internal stresses and improve ductility.

6. Quality Inspection

Finished black tungsten wire undergoes rigorous testing, including diameter accuracy, surface finish, tensile strength, and resistivity. Only qualified tungsten wires can be used in applications such as filaments and cathode emitters.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com