Uses of Tungsten Wire in Modern Industry

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 16:34

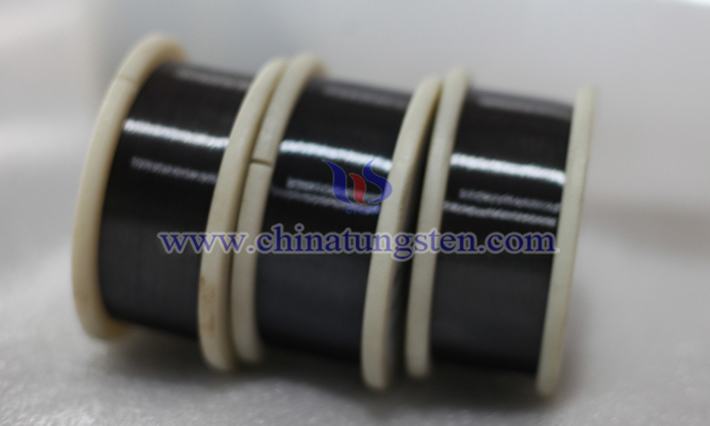

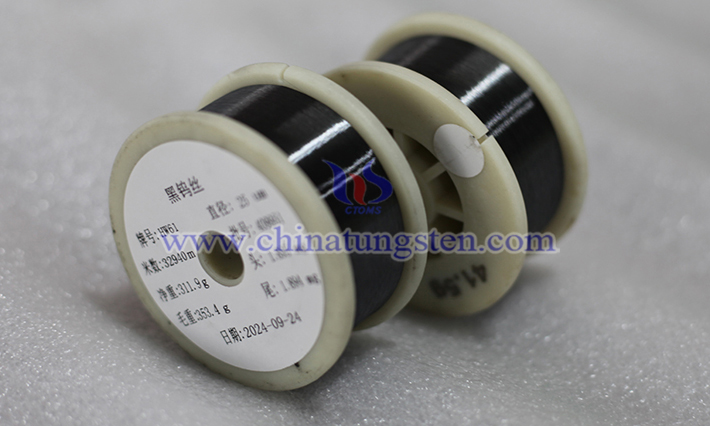

As a key material in modern industry, tungsten wire boasts a wide range of applications due to its high melting point, high hardness, corrosion resistance, electrical and thermal conductivity, and high-temperature stability. It plays an irreplaceable role in lighting, electronics, medical, and new energy fields. Although traditional applications have declined, emerging technologies (such as photovoltaic tungsten wire) are driving continued growth in demand.

Main Applications of Tungsten wire in Modern Industry

1. Lighting Industry

The widespread adoption of LED technology has led to a decline in demand for traditional incandescent lamps, but halogen lamps and specialty lighting still rely on tungsten wire.

Incandescent and halogen lamps: Tungsten wire is doped (such as with potassium, silicon, and aluminum oxide) to enhance its high-temperature sag resistance and extend its life.

Specialty lighting applications, such as high-color temperature lamps and shock-resistant lamps, utilize WB150 and WB584 tungsten wires to withstand extreme operating environments.

2. Electronics and Semiconductors

Gas discharge lamps: Tungsten wires are used as electrodes (such as xenon lamps and mercury lamps). Adding thorium or cerium reduces the electron work function and improves luminous efficiency.

Semiconductor Manufacturing: High-purity tungsten wires are used for micron-scale wires in chip packaging to meet high-precision requirements.

3. High-Temperature Materials

Glass processing equipment: Tungsten wires are used as heating elements, operating stably at 1500°C-2200°C, outperforming nickel-chromium alloy and molybdenum wires.

4. Medical

High-Frequency Electrosurgical Electrodes: Tungsten wires enable precise cutting and hemostasis, reducing thermal damage and are suitable for neurosurgery and ophthalmology.

X-ray Tube Targets: Utilizing tungsten's high atomic number, tungsten efficiently generates X-rays, supporting CT and dental equipment.

Scanning Electron Microscopes (SEMs): Tungsten wires provide high-resolution imaging for pathological research.

5. New Energy and Environmental Protection

Photovoltaic Tungsten Wire Cutting: Replacing carbon steel wire as a diamond wire busbar improves silicon wafer cutting efficiency. Lithium battery current collector: Tungsten-copper composite materials improve battery performance and meet the precision processing requirements of new energy vehicle motors.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com