WSi2/β-SiC Nanocomposite Coating Prepared by CVD

- Details

- Category: Tungsten's News

- Published on Monday, 01 May 2023 12:20

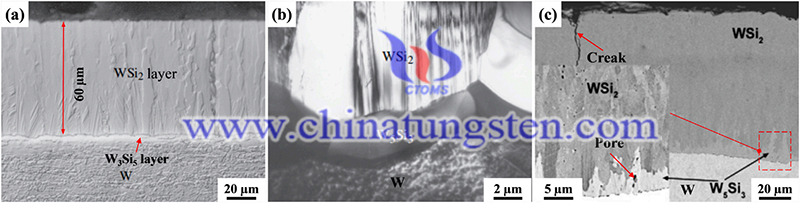

The WSi2/β-SiC nanocomposite coating were obtained by a two-step chemical vapor deposition (CVD) process. EPMA results showed that the carbide coatings consisted of a WC layer and a W2C layer with corresponding thicknesses of 2 and 17 µm, respectively. The WSi2 layer with a thickness of about 50 µm was then obtained by silicification at 1200 °C for 30 min.

As a comparison, a pure WSi2 coating was obtained on the W surface under the same conditions. In the pure WSi2 coating, a typical columnar crystal structure and a thin transition layer can be clearly observed. However, the nanocomposite coating prepared by a two-step deposition process is denser and more uniform in composition. The nanocomposite coating consists mainly of the WSi2 layer, β-SiC layer, WC layer, and W5Si3 layer from the outside to the inside. It is noteworthy that all the coatings have obvious longitudinal cracks, which are caused by the release of thermal stress during cooling and the mismatch of CTE between the coating and the substrate.

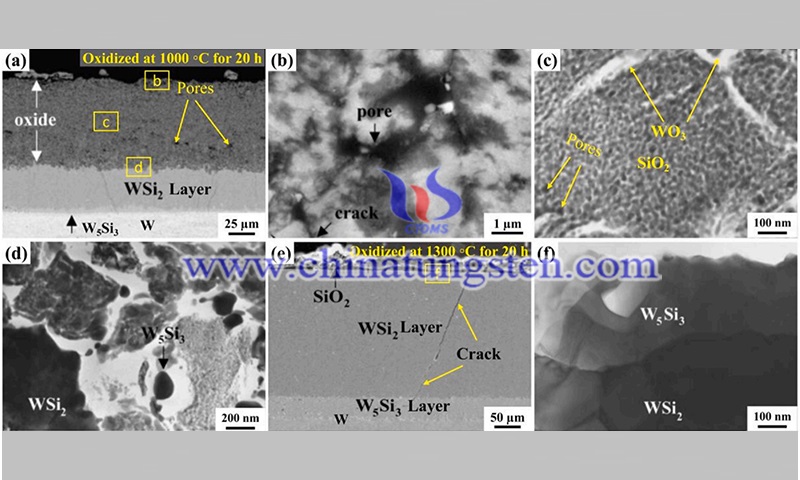

It can be seen that the coating consists of an oxide layer, a WSi2 layer, and a W5Si3 interface layer. The thickness of the W5Si3 layer increases significantly compared to that before oxidation, which is caused by the interdiffusion between the WSi2 layer and the substrate during the oxidation process. In addition, a large number of cracks, pores, and other defects were observed on the surface of the oxidized coating. This is mainly due to the generation of volatile WO3 during the oxidation process.

XTEM results show that the oxide layer of WSi2/β-SiC nanocomposite coatings is mainly composed of SiO2 and a small amount of WO3. W5Si3 particles were observed between the oxide layer and the WSi2 layer. This implies that the oxygen atoms have penetrated the oxide layer and caused some degree of oxidation of the WSi2 layer. The thickness of the interfacial layer increased further under high-temperature oxidation compared to oxidation at 1000 °C and a pure SiO2 layer was observed on the surface. This indicates that the WO3 produced on the surface of the coating has completely evaporated and a continuous W5Si3 layer is observed at the bottom of the oxide layer.

Reference: Fu T, Cui K, Zhang Y, et al. Oxidation protection of tungsten alloys for nuclear fusion applications: A comprehensive review[J]. Journal of Alloys and Compounds, 2021, 884: 161057.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com