Oxidation Behavior of W-Cr-Y-Zr Alloy

- Details

- Category: Tungsten's News

- Published on Sunday, 30 April 2023 14:39

Researchers prepared W-Cr-Y-Zr alloy and investigated its oxidation behavior. Elisa et al. prepared W-10Cr-0.5Y and W-10Cr-0.5Y-0.5Zr (wt%) alloys by HIP and heat treatment (HT) techniques. The surface image results show the morphology of the heat-treated W-10Cr-0.5Y and W-10Cr-0.5Y-0.5Zr (wt%) alloys with heat treatment temperatures and times of 1550°C and 1.5 h.

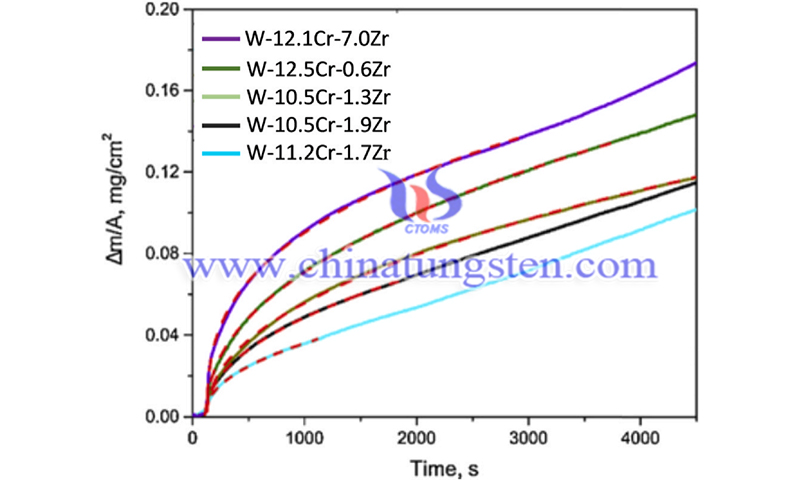

It can be seen that the grain size of the HTed W-10Cr-0.5Y alloy increased significantly and that of the HTed W-10Cr-0.5Y-0.5Zr alloy increased slightly. In addition, some finer nanoparticles were observed at the grain boundaries of the HIPed alloys, and these particles were widely distributed on the surface of the HIP+HT alloys. Oxidation tests showed that the oxidation rates of all the alloys were lower than those of pure tungsten, and the addition of Zr reduced the oxidation rate of the W-10Cr-0.5Y alloy to some extent.

In addition, heat treatment has a positive effect on reducing the oxidation rate of the W-10Cr-0.5Y alloy, but it has little effect on the W-10Cr-0.5Y-0.5Zr alloy. In the initial stage of oxidation, the mass increase of W-10Cr-0.5Y-0.5Zr alloy has a little change before and after HT. However, after 25 h, the mass gain of the HTed alloy increased suddenly and then gradually stabilized. The author believes that this may be related to the destruction of the protective film of Cr2O3 and its subsequent repair.

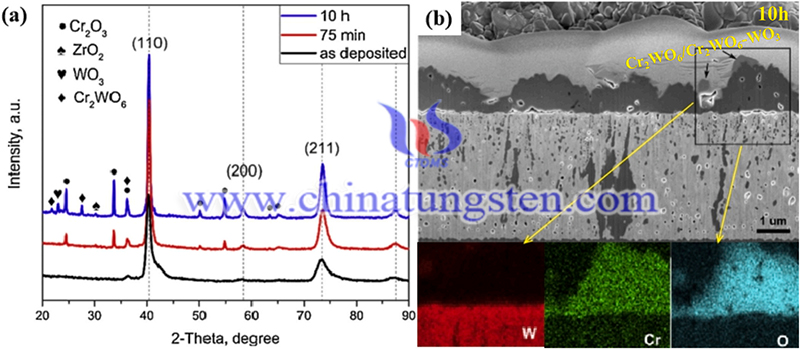

The results of EDS and XRD analysis show that the oxide layer of the alloy consists of a Cr2O3 layer, a Cr2WO6 layer, and a thicker WO3 layer. In addition, a small amount of Cr2O3 was also observed at the interface between the oxide layer and the substrate, which indicates that oxygen passes through the entire oxide layer and leads to the oxidation of the alloy substrate. It is noteworthy that the thickness of the oxide layer is around 17 μm for both alloys, which implies that the addition of Zr is not sufficient to change the oxidation properties of the W-10Cr-0.5Y alloy.

Reference: Fu T, Cui K, Zhang Y, et al. Oxidation protection of tungsten alloys for nuclear fusion applications: A comprehensive review[J]. Journal of Alloys and Compounds, 2021, 884: 161057.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com