Tungsten Alloys Build Next-Generation Materials for Nuclear Fusion

- Details

- Category: Tungsten's News

- Published on Saturday, 25 March 2023 23:16

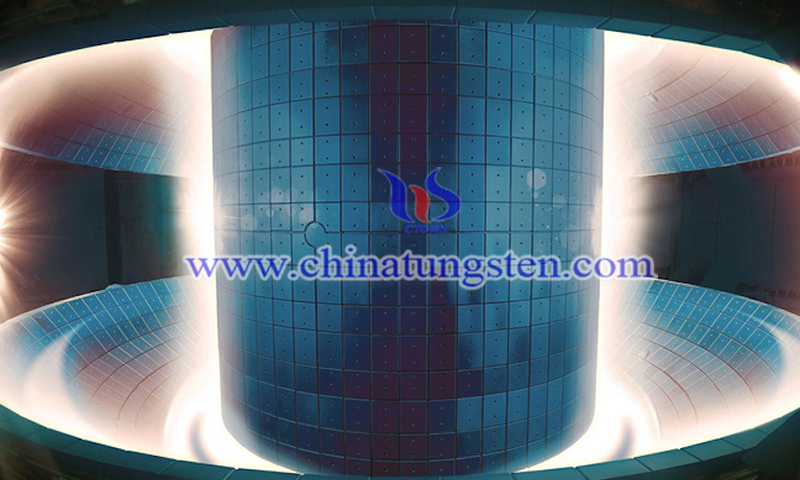

Researchers at Lawrence Livermore National Laboratory (LLNL) announced that they observed the first net increase in fusion energy at the end of 2022 and they showed how tungsten alloys could be improved for use in advanced nuclear fusion reactors. This study could be a landmark study because the enormous energy produced by fusion could provide a carbon-neutral pathway for millions of homes and businesses. However, translating this achievement into practical nuclear energy will require innovative technologies to bring a fusion-powered society to reality.

Scientists at Virginia Polytechnic Institute and State University and the Pacific Northwest National Laboratory are working to make this goal a reality through their efforts in materials research. Their recent work, published in Scientific Reports, includes a look at tungsten alloys and shows how the metal can be improved by replicating the structure of a shell for use in advanced nuclear fusion reactors. Jacob Haag, the study's first author, said this is the first study of this material interface on a very small scale. They also reveal some of the fundamental mechanisms that govern the material's toughness and durability, he added.

The sun has a core temperature of about 27 million degrees Fahrenheit and is powered by nuclear fusion. Before scientists can harness the energy from these reactions and turn it into power, they need to develop advanced fusion reactors that can withstand the high temperatures and irradiation conditions that occur in fusion reactions.

Tungsten has the highest melting point of any element available on Earth. This makes it one of the best materials for nuclear fusion reactors. However, this metal can also be brittle and needs to be mixed with other metals to reduce brittleness. Mixing it with other metals, such as iron and nickel, can help create an alloy that is harder than tungsten, but retains its nature properties.

Using a special hot-rolling method, the researchers made tungsten heavy alloys with microstructures similar to mother-of-pearl or pearls in shells due to the high strength of pearls. a team of researchers at PNNL and Virginia Tech studied heavy tungsten alloys close to pearls for potential nuclear fusion applications. Haag said, "We're trying to know why these materials have almost unheard-of mechanical capabilities in metals and alloys."

To examine the microstructure of the alloy, Haag and his team used advanced techniques such as scanning transmission electron microscopy to analyze the atomic structure of the alloy. In addition, they worked on mapping the nanoscale composition of the material by combining atom probe tomography and energy dispersive X-ray spectroscopy.

Heavy tungsten alloys are composed of two separate phases that coexist within a pearl-like structure: a "hard" phase of almost pure tungsten and a "ductile" phase consisting of a combination of nickel, iron and tungsten. The results point to a good connection between the different phases, including the closely coupled "hard" and "ductile" phases, which are the source of the high strength of the tungsten heavy alloy.

According to Wahyu Setyawan, a computational scientist at PNNL and co-author of the study, "The two distinct phases produced a tough composite, but they posed a significant obstacle to generating high-quality characterized specimens. This allowed us to expose the precise structure of the interphase boundaries and the chemical grading across these boundaries thanks to the superb work of our team members."

This work shows how strong material interactions in heavy tungsten alloys are influenced by crystal structure, geometry and chemistry. It also shows ways to enhance the design and properties of materials for fusion applications, and Haag explained the safety and durability of these duplex alloys must be optimized if they are to be used in nuclear reactors.

The results of this study have been extended at multiple levels at PNNL and in the scientific research community. PNNL is also conducting multi-scale materials modeling to optimize structures and test the strength of materials with different interfaces. In addition, they are working to see how these materials behave under the extreme temperature and irradiation conditions of fusion reactors.

Reference: https://interestingengineering.com/science/metal-alloys-may-support-nuclear-fusion-energy

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com