Thermal Fatigue Damage Mechanism of Strengthened Tungsten Alloy Composites

- Details

- Category: Tungsten's News

- Published on Saturday, 25 March 2023 23:01

A research group at the Hefei Institute of Materials Science (HFIPS), Chinese Academy of Sciences, recently investigated the relationship between microstructure evolution and property degradation of two representative second-phase dispersion-reinforced tungsten alloy composites after thermal fatigue damage of electron beam thermal loading, and the related study was published in the Journal of Materials Science & Technology.

In magnetic confinement fusion devices, plasma-oriented tungsten (W) materials are directly exposed to the high-temperature plasma and are typically subjected to transient thermal shocks of about 1 GW/m2 and steady-state thermal loads of 5 to 20 MW/m2. This helps to raise the surface temperature of tungsten above 1800 °C. The high heat flux loads to which W is subjected can lead to some irreversible material damage, such as surface cracking, roughening and surface melting. Therefore, there is an urgent need to evaluate the thermal load capacity of W materials.

(Image Credit: ZHAO Weiwei)

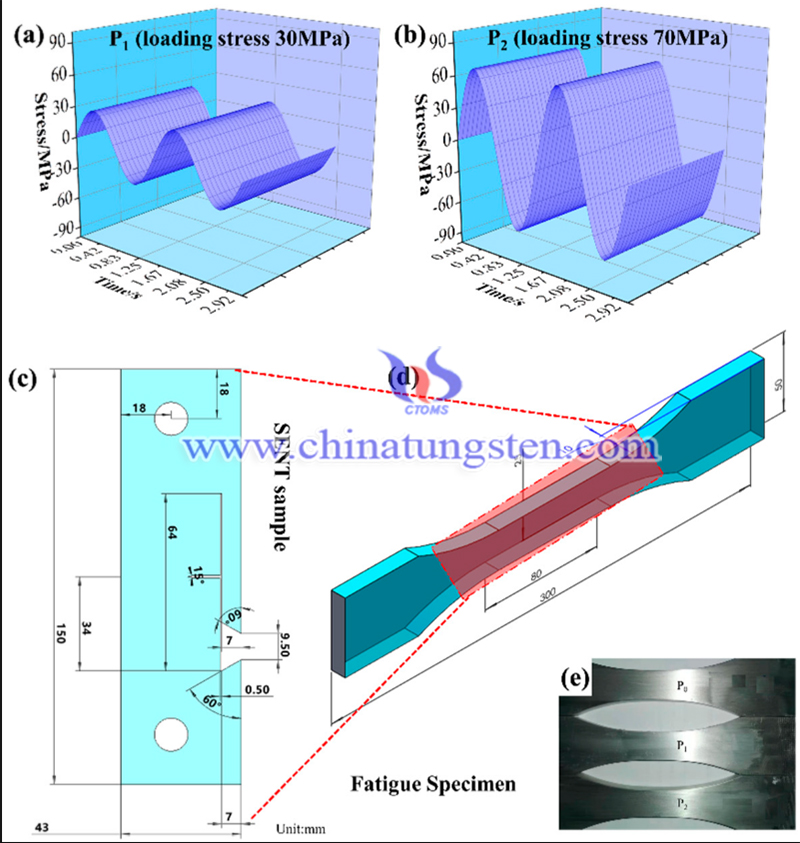

In this study, scientists subjected an electron beam device, the Electron Beam Materials Research Platform (EBMP-30), to repeated thermal loads of up to 30 kilowatts of power. The platform is designed to calculate the thermal shock resistance of plasma-oriented materials (PFMs).

"It employs a 30 kW welding electron beam with a maximum acceleration voltage of 100 kV that can scan an area of 30 x 30 mm2 with a maximum frame rate of 35 kHz and a pulse duration that can vary from 100 ms to a continuous state." XIE Zhuoming explained that he was involved in the construction of the platform. Relying on the EBMP-30 equipment, two representatives W-0.5 wt% ZrC (WZC) and W-1.0 wt% Y2O3 (WYO) composites were selected to understand damage behavior induced by repeated steady-state thermal loading with absorbed power densities (APD) in the range of 10 to 30 MW/m2.

(Image Credit: Chen/Metals)

At a thermal load of 22 MW/m2, the WZC specimen maintained a high ultimate tensile strength of 816 MPa due to its high recrystallization temperature (~1300 °C). The fine and uniform distribution of ZrC particles and a CTE comparable to that of the W matrix effectively prevented ZrC particle exfoliation and microcrack formation. Xuebang Wu, study lead author, Hefei Institute of Materials Science, Chinese Academy of Sciences Research Institute.

Wu added, "This study reveals the relationship between microstructural evolution and property degradation in two representative second-phase dispersion strengthened tungsten alloy composites, as well as the mechanism of fatigue damage induced by high thermal loading, providing an important reference for further development of high-performance tungsten materials."

Journal Reference: Wang, H., et al. (2022) Microstructural evolution and thermal fatigue damage mechanism of second-phase dispersion strengthened tungsten composites under repetitive thermal loads. Journal of Materials Science & Technology. doi.org/10.1016/j.jmst.2022.09.007

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com