Additive Manufacturing of Refractory Tungsten and Tungsten Alloys

- Details

- Category: Tungsten's News

- Published on Monday, 25 July 2022 21:18

A team of researchers from the University of California, Texas A&M University, Lawrence Livermore National Laboratory (LLNL), and Oak Ridge National Laboratory (ORNL) has published a review of the use of additive manufacturing of refractory tungsten and tungsten alloys in the journal Additive Manufacturing.

(Credit: Alberico Talignani/Additive Manufacturing)

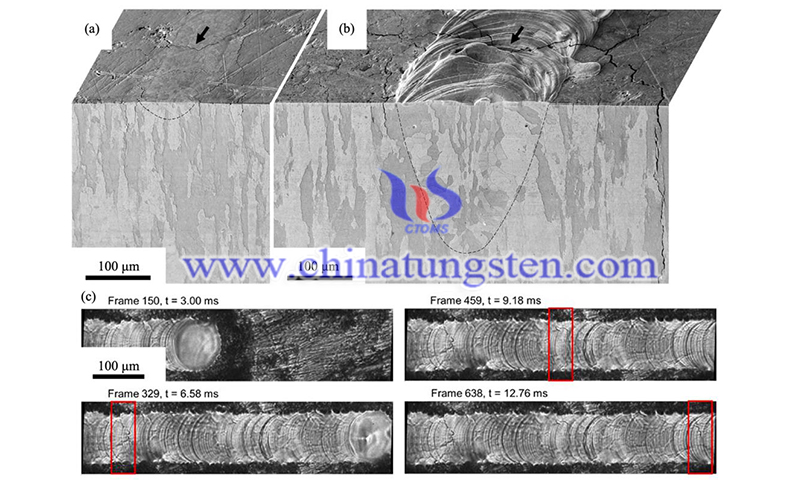

Tungsten and tungsten alloy are used in various industrial applications due to their high melting point (tungsten holds a melting point of about 3400°C) and high density, among other properties. However, due to this melting point, tungsten is difficult to use for laser beam or electron beam powder bed fusion (PBF-LB or PBF-EB, respectively), while tungsten alloys are typically processed by these techniques and directed energy deposition (DED) additive producing.

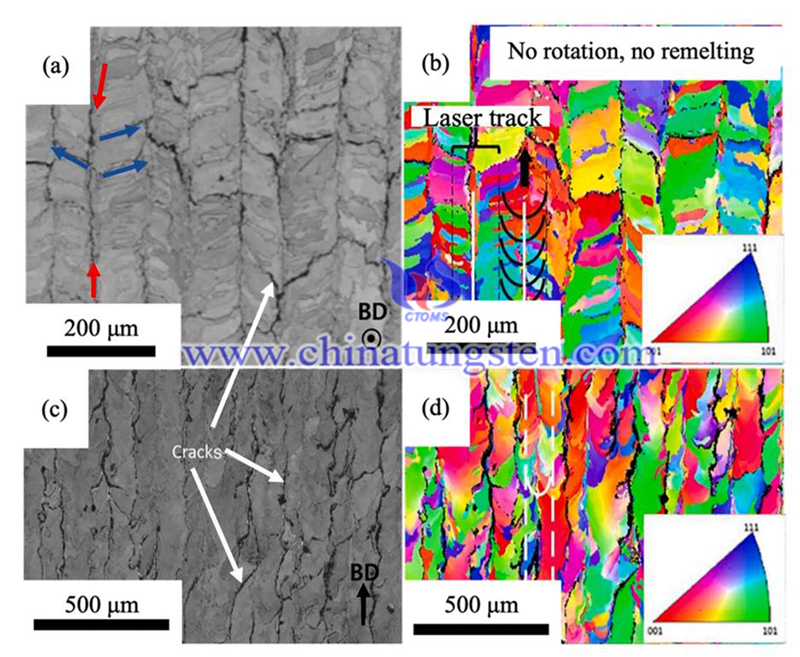

This paper notes that the cracking problem is particularly relevant to the PBF-LB process as it relates to tungsten. To reduce cracking, the researchers investigated combining pure tungsten powder with 1, 5, and 10 percent tantalum (Ta) powder. 5 percent Ta blends were shown to reduce grain size, although 10 percent Ta showed no further reduction. The researchers also reported solutions by changing tracking techniques, recrystallization, and reheating of the substrate, thereby reducing (or eliminating) any tension created during additive production of tungsten.

In their research, the team also found that the problems associated with DED additive manufacturing, namely thickness building, permeability, and splitting, can also be addressed by parameter optimization, good material integrity, and surface preheating.

(Credit: Alberico Talignani/Additive Manufacturing)

To date, relatively little research has been done on PBF-EB additive production of refractory tungsten and tungsten alloy. A review on the additive making of refractory tungsten and tungsten alloys reports that their bond strength is lower than that of standard wrought tungsten.

This paper titled: “A review on additive manufacturing of refractory tungsten and tungsten alloys” was published in Additive Manufacturing, Volume 58, 2022,103009, and was authored by Alberico Talignani, Raiyan Seede, Austin Whitt, Shiqi Zheng, Jianchao Ye, Ibrahim Karaman, Michael M Kirka, Yutai Kato, and Y Morris Wang.

(Source: Metal AM)

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com